Horizontal flux flat-plate type permanent-magnetic linear electric machine

A permanent magnet linear motor, transverse magnetic flux technology, applied in electrical components, electromechanical devices, electric components, etc., can solve problems such as low force density, large edge effect, and difficulty in producing laminations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

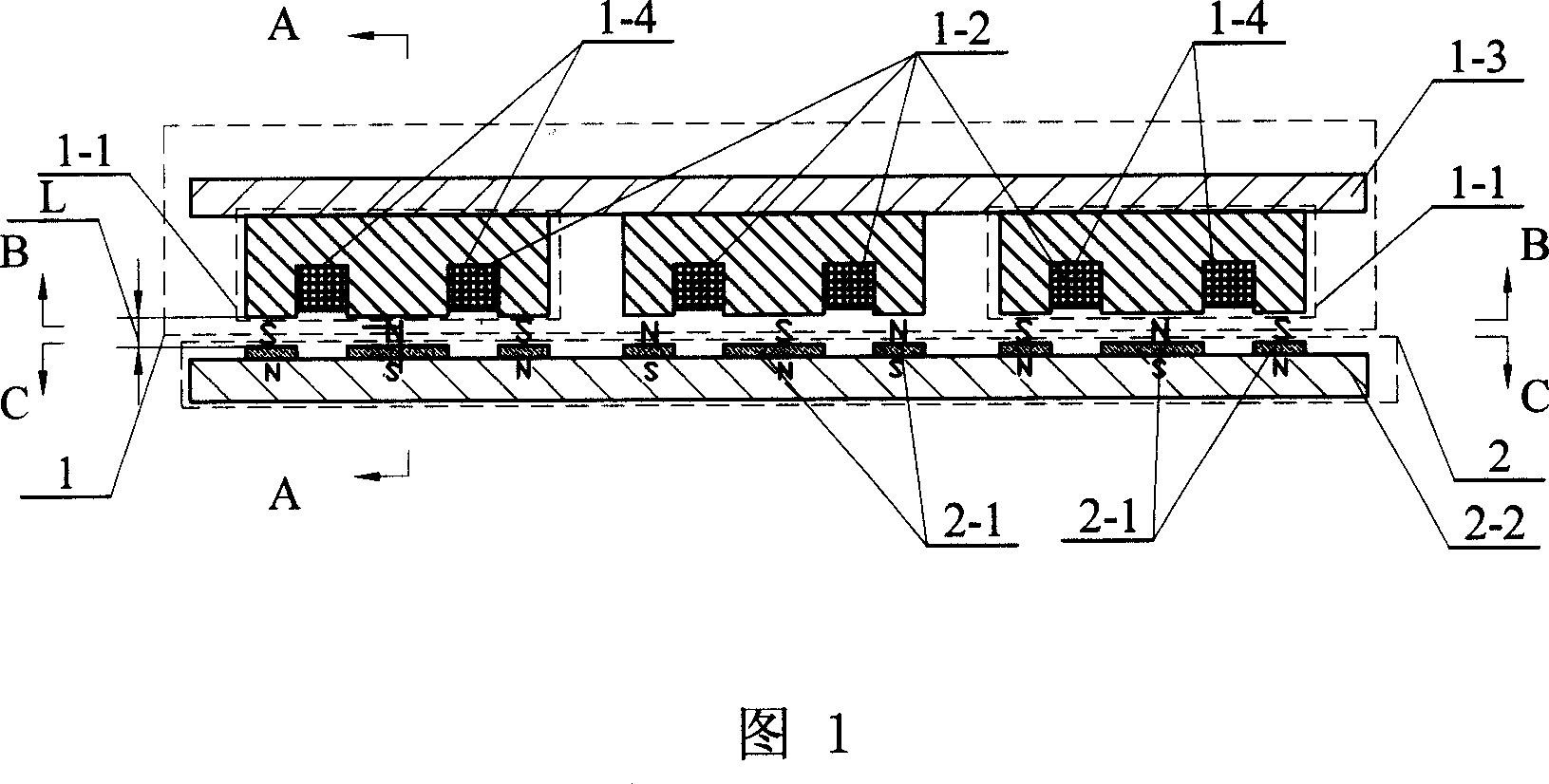

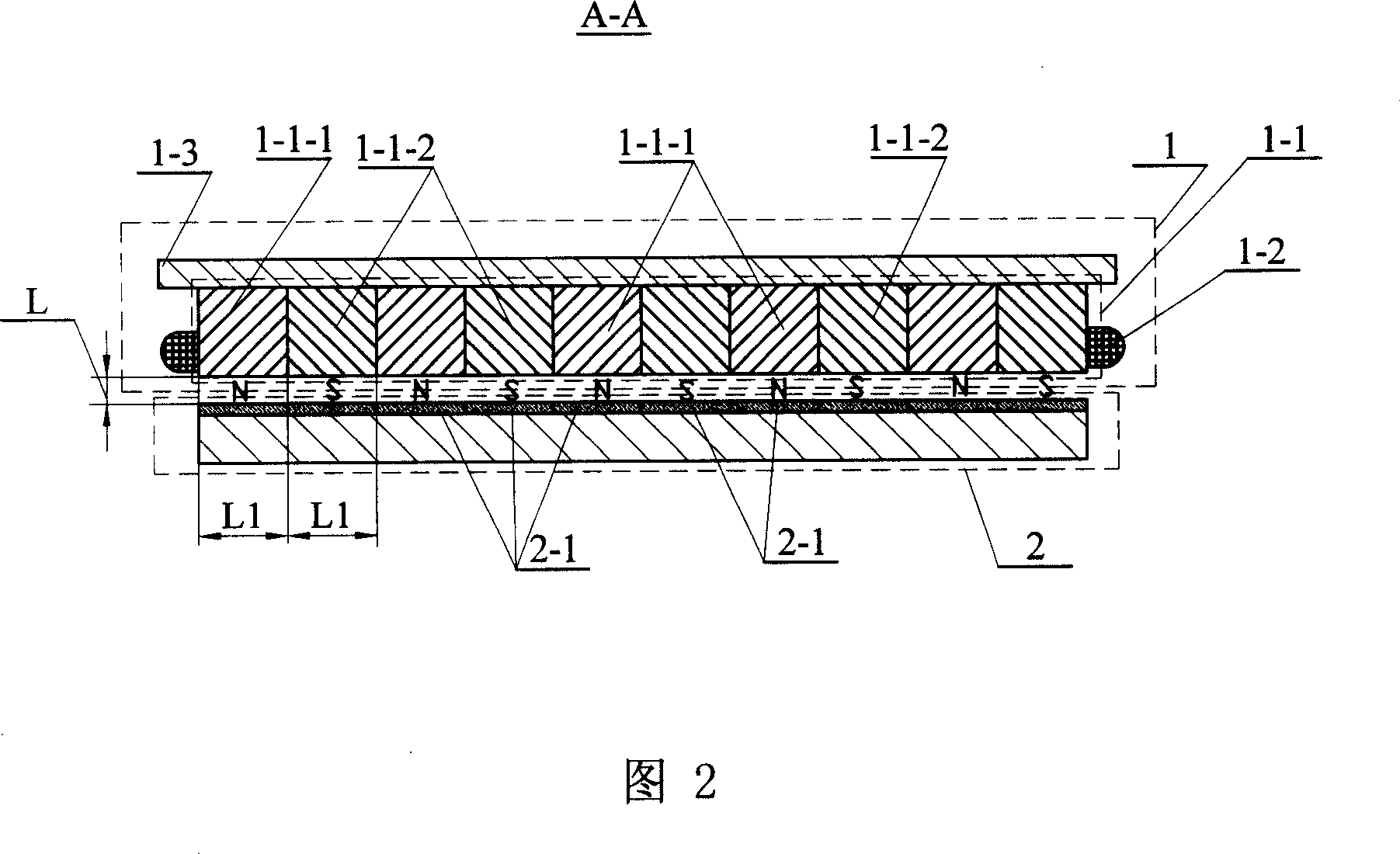

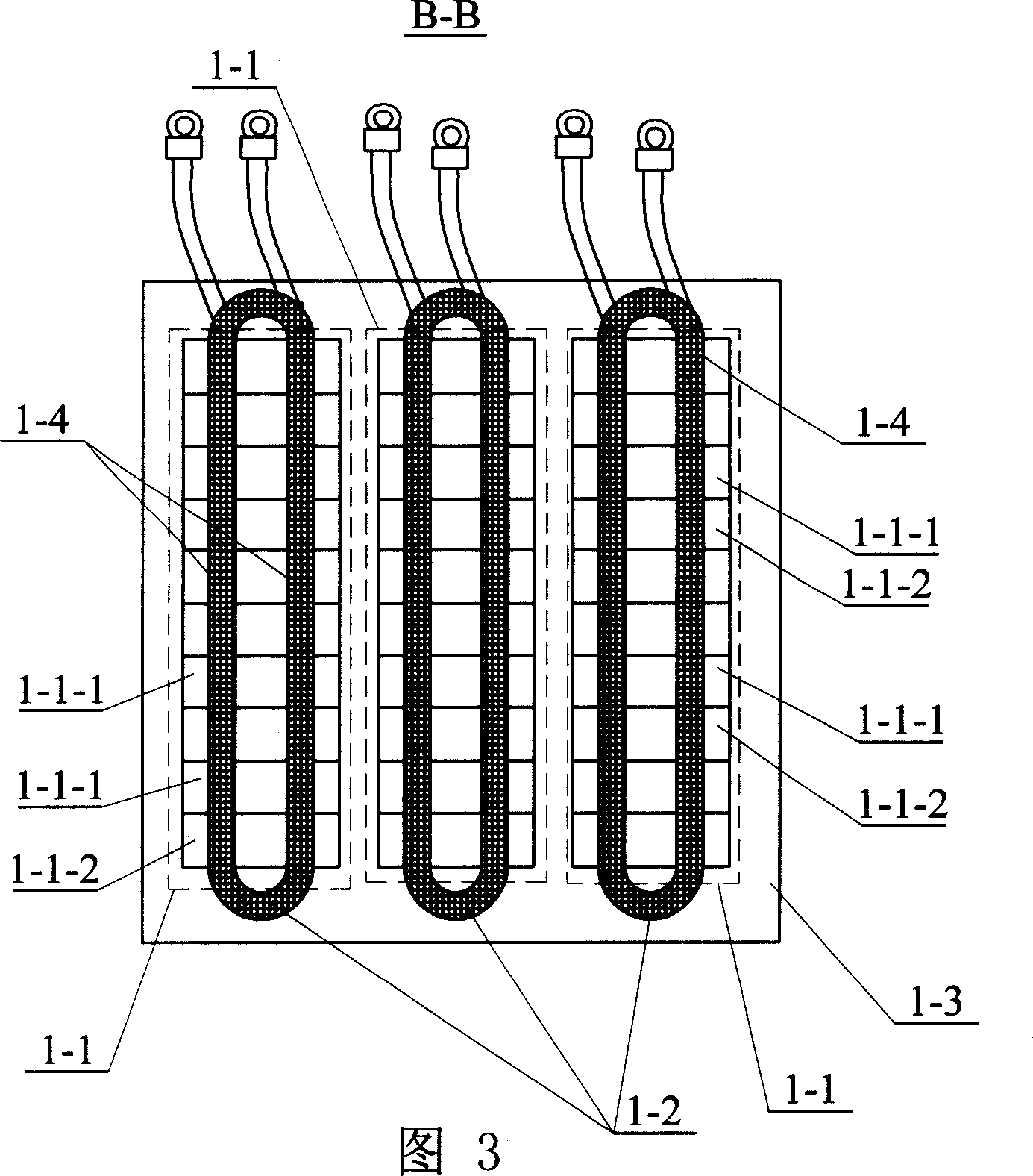

[0011] Specific implementation mode 1: This implementation mode is described in conjunction with FIG. 1 , FIG. 2 , FIG. 3 , and FIG. 4 ;

[0012] This embodiment is composed of a first primary 1 and a permanent magnet secondary 2; the first primary 1 is composed of a plurality of E-shaped cores 1-1, windings 1-2, and a bottom plate 1-3;

[0013] The E-shaped outer bottom end surfaces of multiple E-shaped cores 1-1 are arranged side by side with gaps on one side of the bottom plate 1-3; the slots 1-4 of multiple E-shaped cores 1-1 are jointly embedded with windings 1- 2; each E-shaped core 1-1 is composed of a plurality of E-shaped magnetic permeable blocks 1-1-1 and a plurality of E-shaped magnetic isolation blocks 1-1-2 arranged evenly with each other; all of the first primary 1 There is a gap L between the end faces of the three claws of the E-shaped core 1-1 and one end face of the permanent magnet secondary 2;

[0014] In one end face of the permanent magnet secondary 2, ...

specific Embodiment approach 2

[0016] Embodiment 2: This embodiment is described with reference to FIG. 7 . On the basis of Embodiment 1, each E-shaped magnetic permeable block 1-1-1 is composed of several iron core sheets 1-1-3 superimposed.

specific Embodiment approach 3

[0017] Specific embodiment three: This embodiment is described in conjunction with Fig. 5 and Fig. 6. On the basis of specific embodiment one, a second primary 3 is added, and the composition and connection relationship of the second primary 3 are the same as those of the first primary 1. The other side end face of the magnetic secondary 2 is increased with three claw surfaces of each E-type magnetic permeable block 3-1-1 in the second primary 3 or three claw faces of each E-type magnetic isolation block 3-1-2. The permanent magnet blocks 2-3 with claw faces facing each other respectively, the arrangement mode and magnetization direction of all permanent magnet blocks 2-3 are the same as the arrangement mode and magnetization direction of all permanent magnet blocks 2-1; The winding 1-2 is connected in series with the winding 2-2 in the second primary 3 in the same phase and forward direction. This embodiment can improve the force density of the motor and eliminate the adverse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com