Open/close cap and manufacturing method thereof

A cap-closing, circumferential technology, applied in the directions of bottle/container cap, capping, closing, etc., can solve the problems of disconnection, deformation, and inability to realize anti-tampering function of connecting parts and connecting parts, so as to achieve anti-tampering opening. , The effect of preventing the deformation of the belt ring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

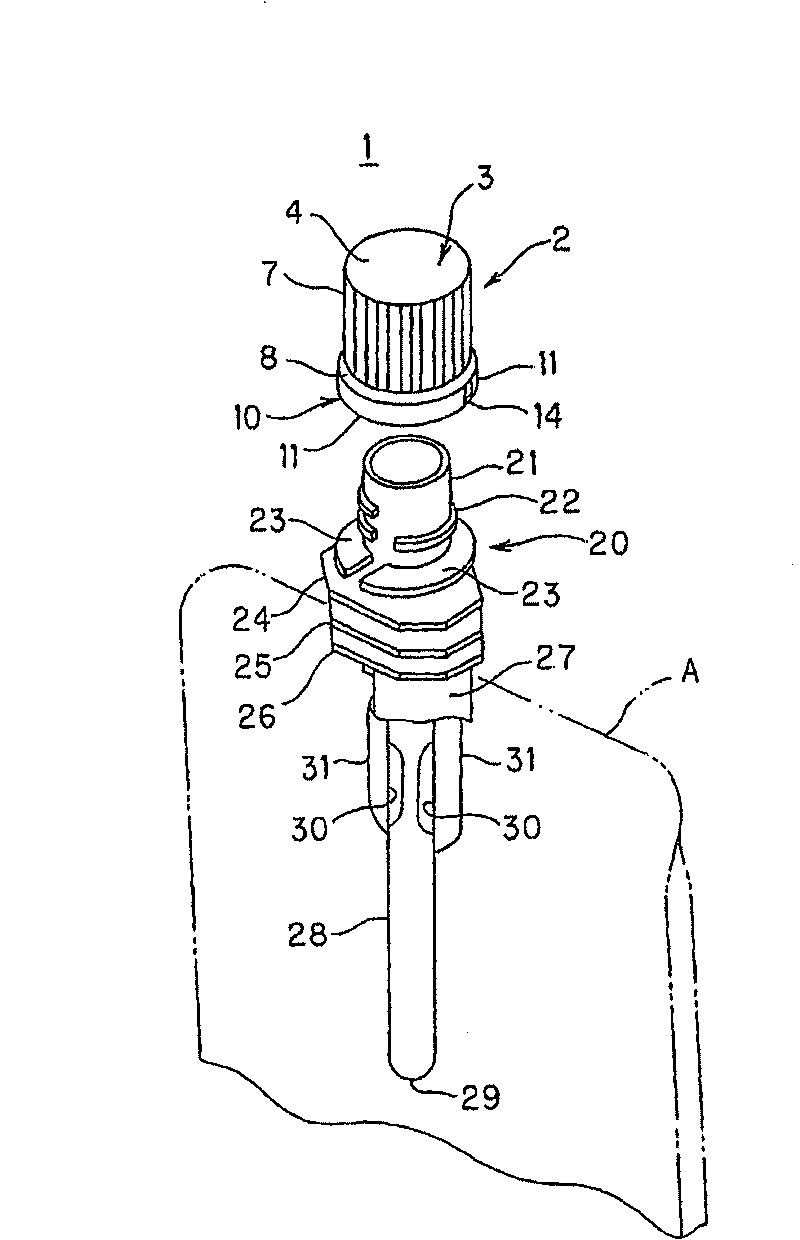

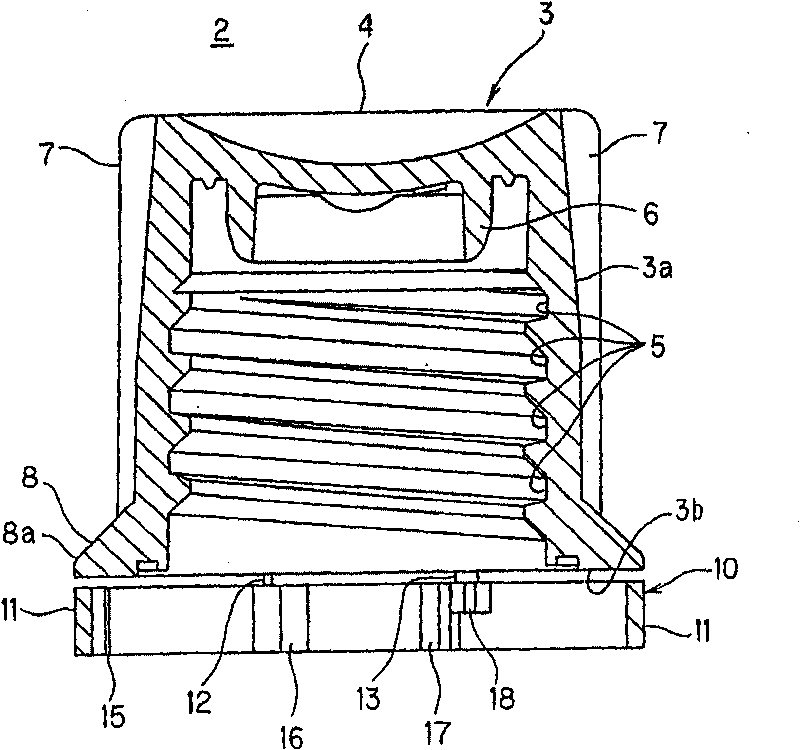

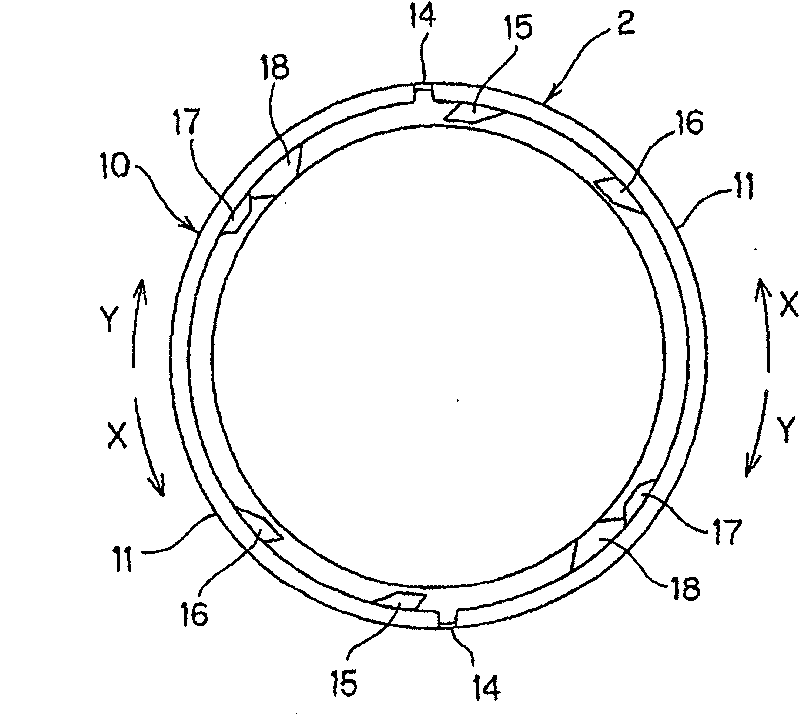

[0067] figure 1 The perspective view of is showing a spout plug device 1 sealing a pouring spout 20 of a container A having an opening / closing cap 2 according to an embodiment of the present invention. The spout device 1 includes a pouring spout 20 mounted on the top of the container A and an opening / closing cap 2, the opening / closing cap 2 is formed on the top of the pouring spout 20 so as to be threadedly engaged with the mouth 21 to open or close the pouring spout 20 . The spout device 1 is attached to the upper end of the container A by inserting the lower portion of the pouring spout 20 into the container A. As shown in FIG. Viewed from the top of the opening / closing lid 2, when the opening / closing lid 2 is rotated clockwise, the lid 2 is tightened downwards with the pouring spout 20 and the spout plug device 1 seals the mouth 21, on the contrary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com