Process to produce synthetic fuels and lubricants

A technology for synthesizing lubricants and lubricants, applied in hydrocarbon distillation, hydrocarbon oil treatment products, hydrocarbon oil treatment, etc., can solve the problems of expensive equipment and catalyst purchase and operation, and achieve the effect of increasing total capital efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

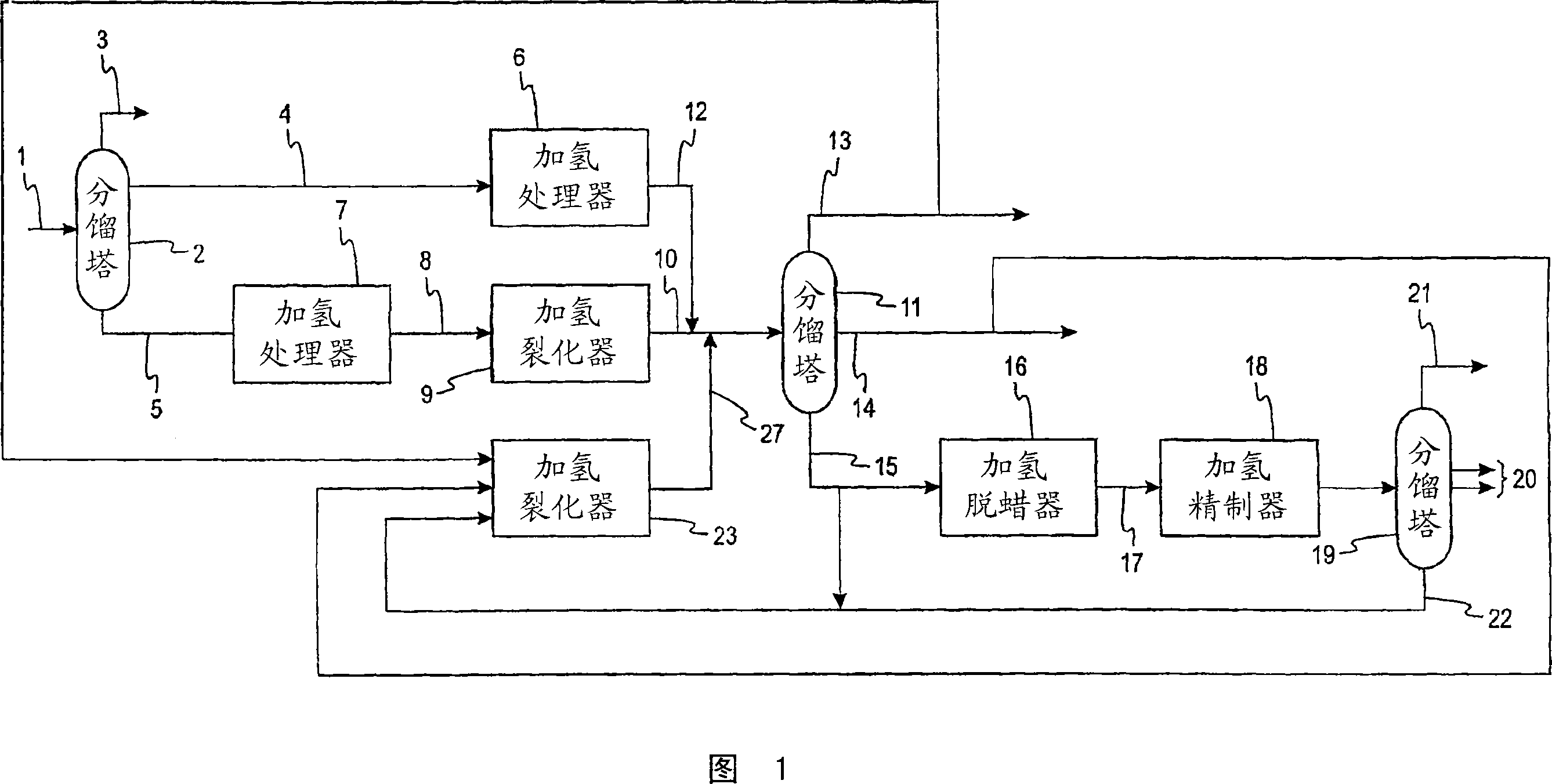

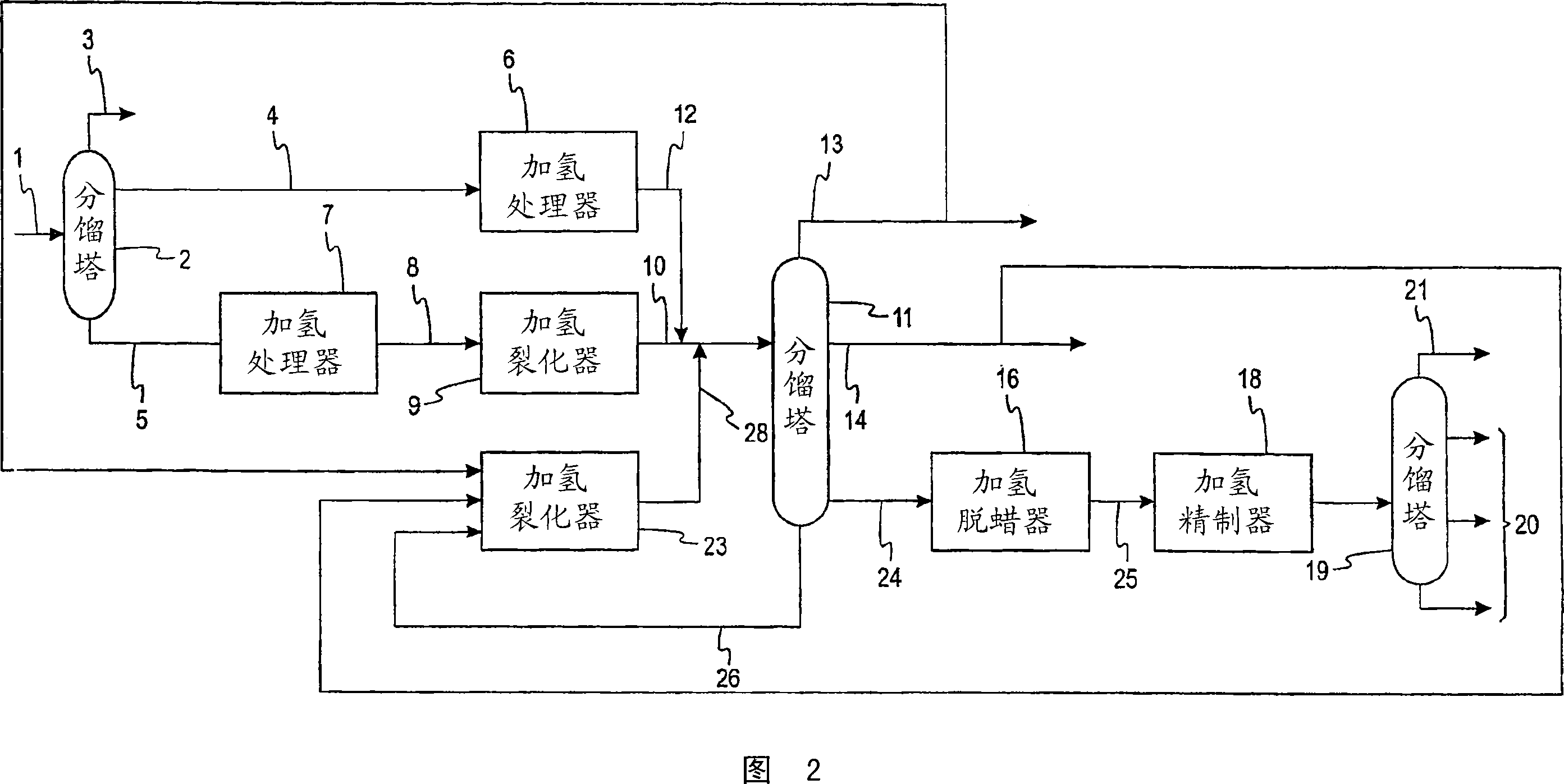

[0020] The process of the present invention first uses a low-severity hydrocracker to process a waxy feed heavier than distillate fuel into a lower turbidity and / or freezing point distillate fuel, and converts heavy isoparaffins suitable for dewaxing The stream is processed either catalytically or by solvent extraction to low pour point isoparaffinic base stocks of exceptionally high viscosity index and low volatility.

[0021] Feeds useful in the process of the present invention are typically characterized as broad boiling range petroleum derived feeds including: heavy gas oils containing about 50% by weight components boiling above 371°C [700°F] or Contains vacuum gas oils boiling in the range between about 316°C [600°F] and about 566°C [1050°F]. Alternatively, the feed may be all or part of the product from synthesis, eg Fischer-Tropsch synthesis.

[0022] In one embodiment of the present invention, the method for improving feed quality is integrated with Fischer-Tropsch s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com