Offline teaching apparatus for robot

An off-line teaching and robot technology, applied in the direction of instruments, simulators, manipulators, etc., can solve problems such as the range and difficulty of spaces where the safety of robot actions cannot be confirmed, and the difficulty of optimizing teaching information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be described in detail below with reference to the drawings. In the drawings, the same or similar components are given common reference signs.

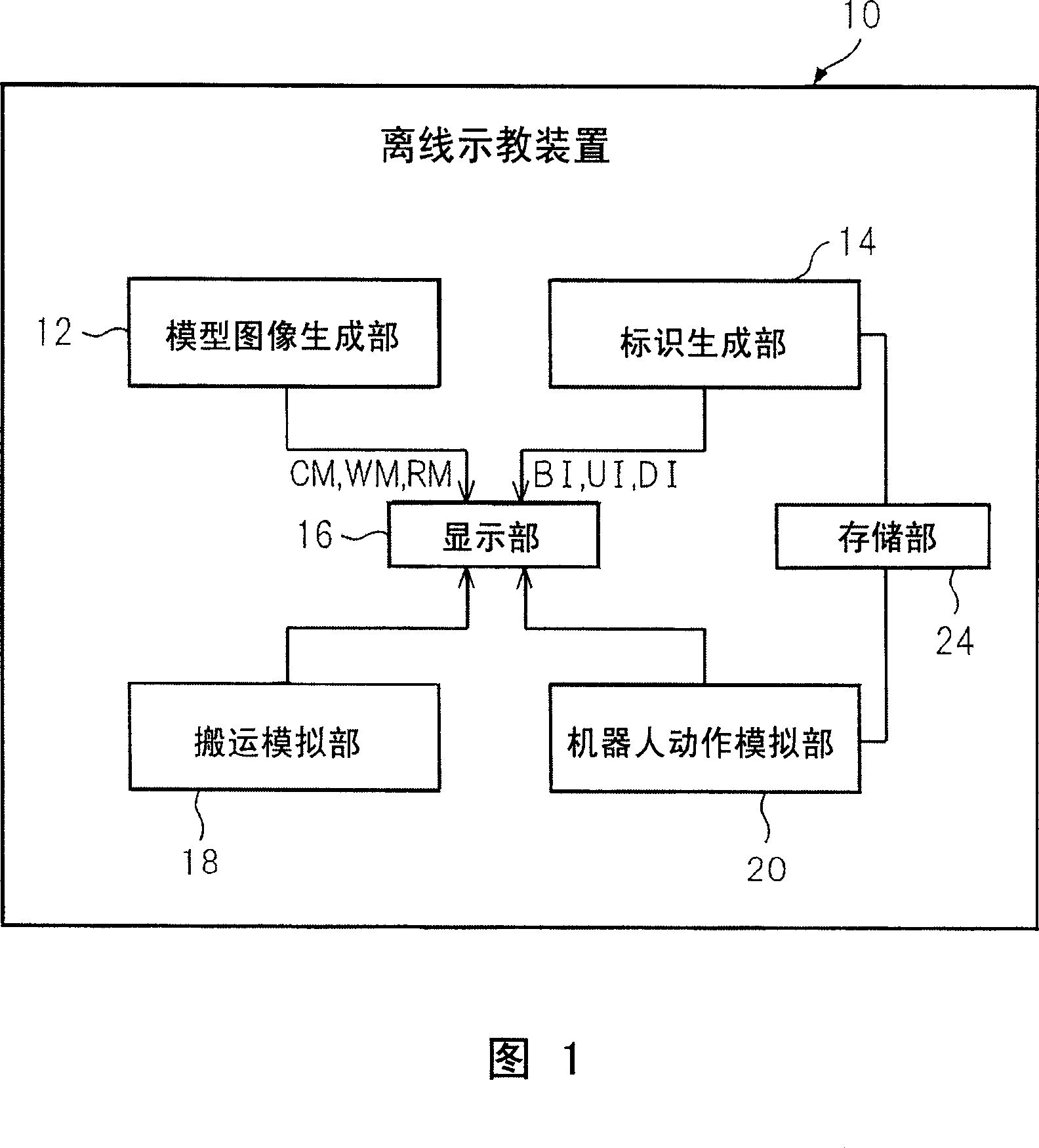

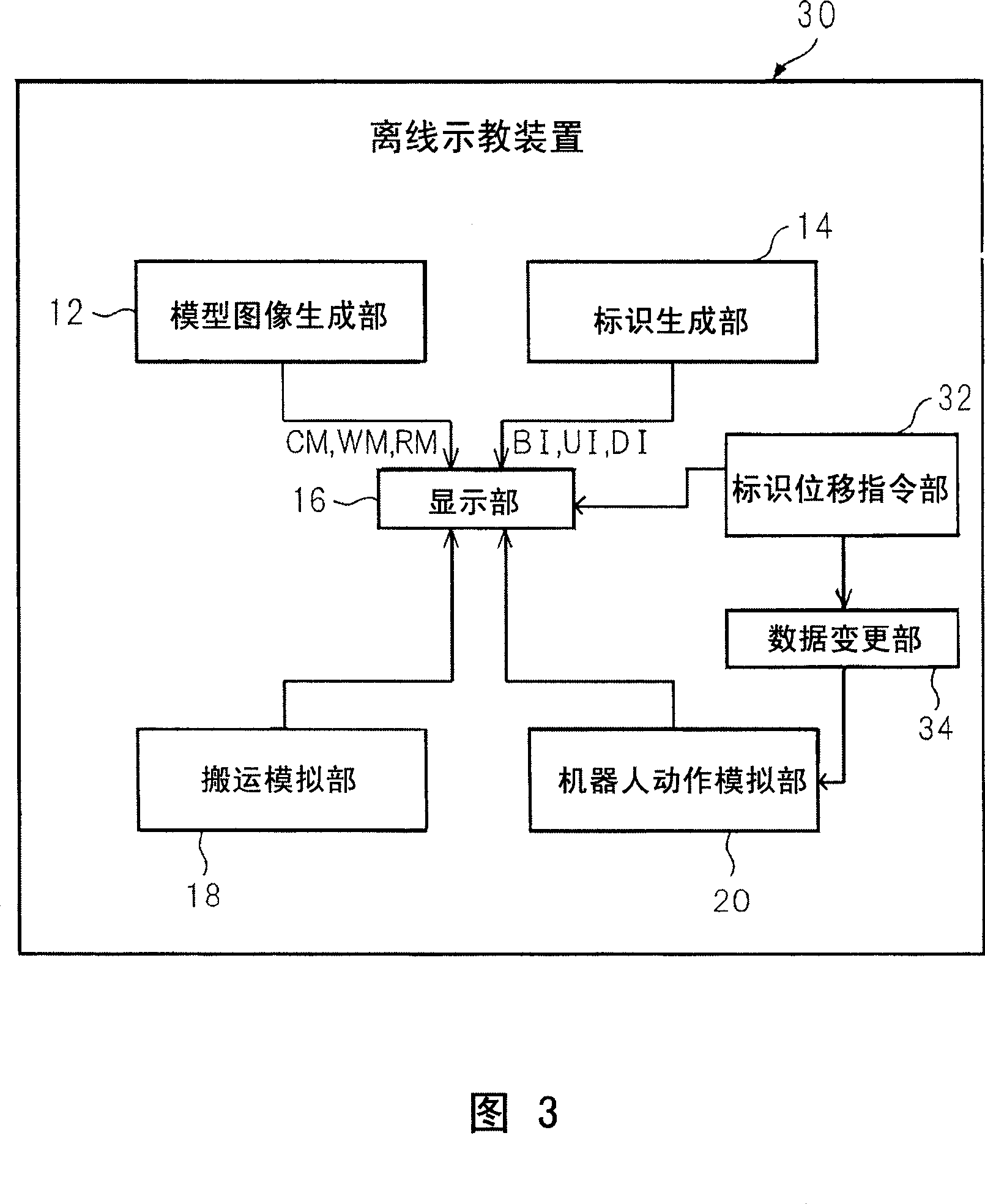

[0020] Referring to the drawings, FIG. 1 is a functional block diagram showing the basic structure of the offline teaching device 10 of the present invention. Off-line teaching device 10, while tracking the workpiece moving along the conveying path, generates and teaches offline the robot's motion about tracking and operation of the robot performing the operation on the workpiece, for example, by installing the software required by electronic computers such as personal computers to form.

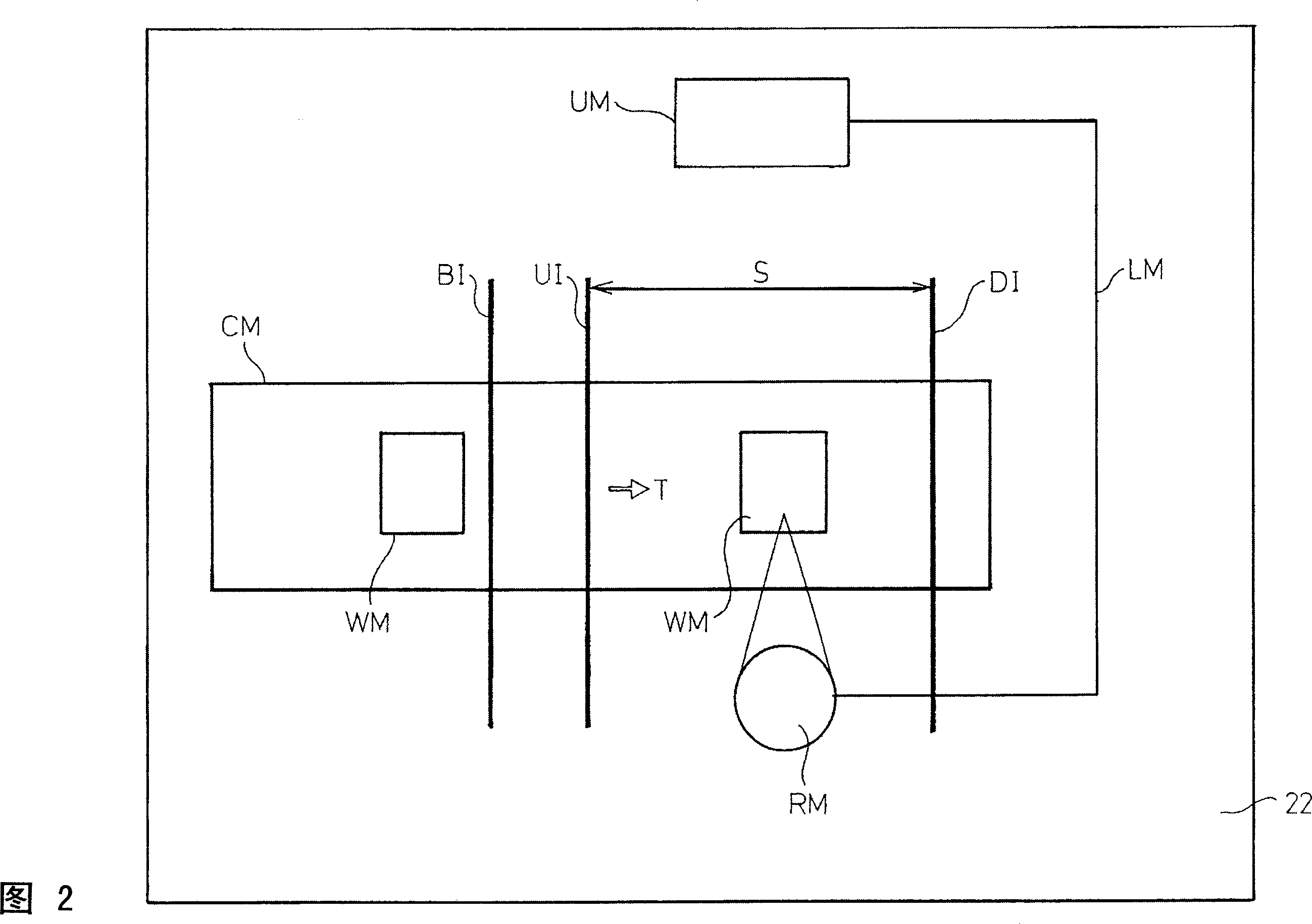

[0021] The offline teaching device 10 is configured to include: an image generating unit 12 that generates images of a model CM, a workpiece model WM, and a robot model RM modeled on the conveyance path, workpiece, and robot conveyance path; , which generates the reference point mark BI representing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com