Automatic vending machine

A vending machine and casing technology, applied in the direction of instruments, coin-operated equipment for distributing discrete items, coin-operated equipment for distributing discrete items, etc., can solve vending machine failures, decreased work efficiency, wire burning To prevent problems such as breakage, to prevent the decline in work efficiency, reduce the possibility of failure, and reduce the possibility of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

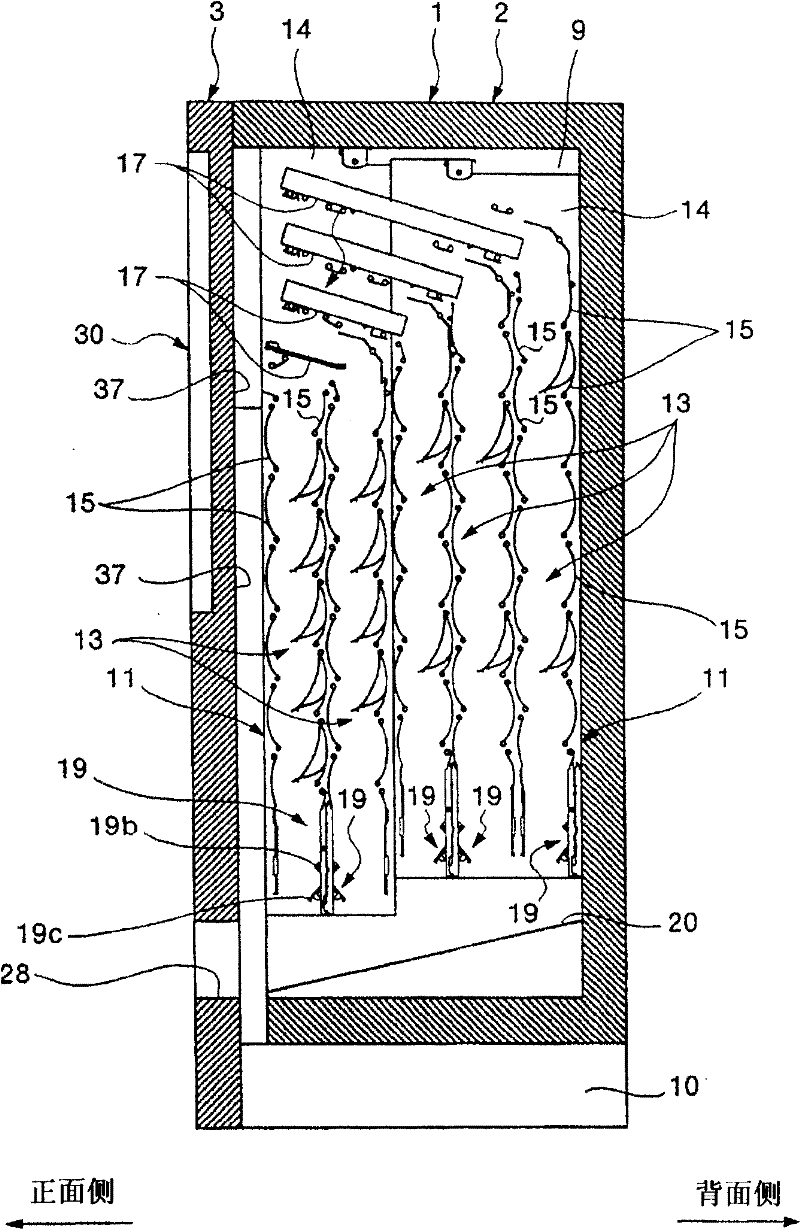

[0026] Specific embodiments of the automatic vending machine according to the present invention will be described in detail below with reference to the accompanying drawings.

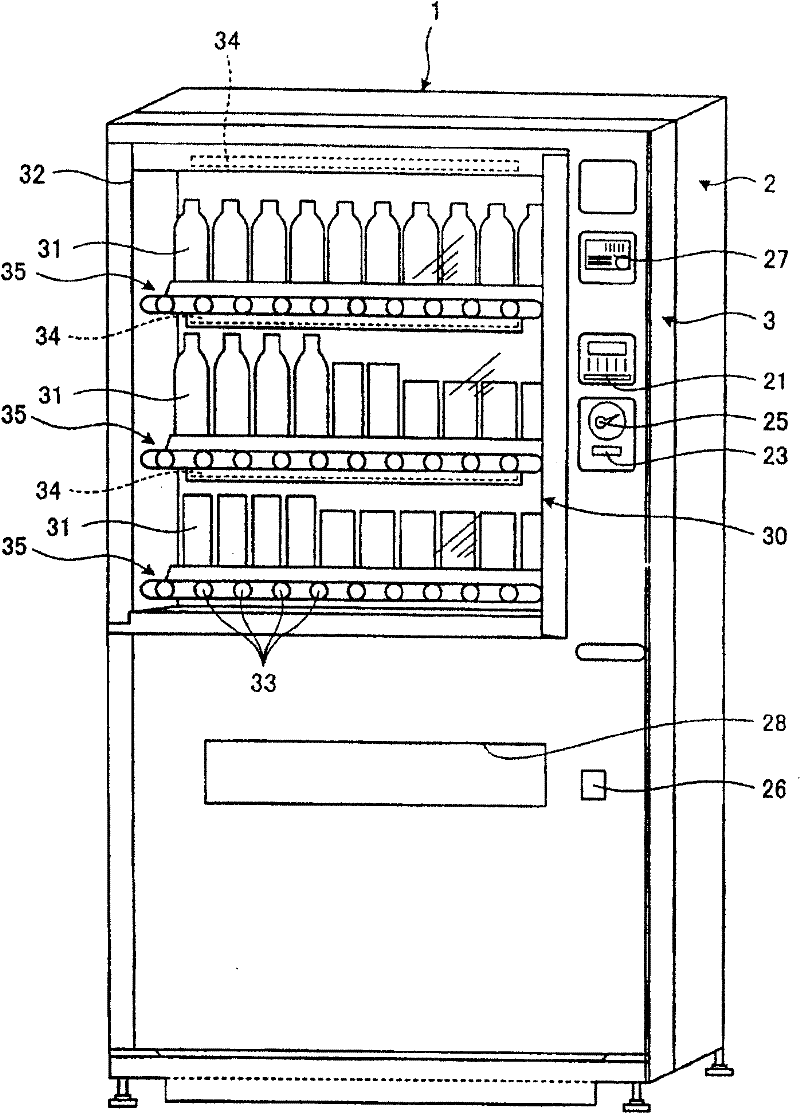

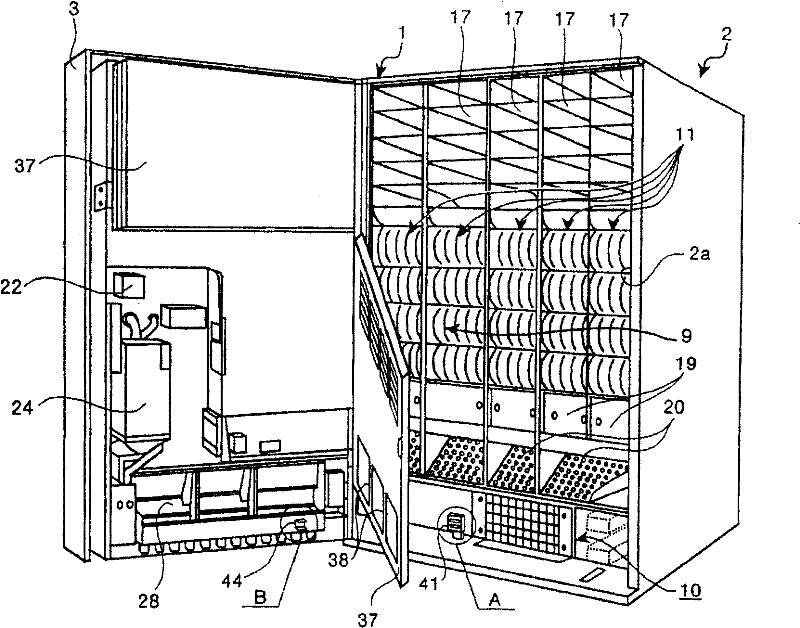

[0027] Figure 1 to Figure 3 The vending machine 1 according to the present invention is shown. The vending machine 1 illustrated here sells containerized beverages such as canned beverages, bottled beverages, soft-packed beverages, and plastic bottled beverages as commercial products, and a door (outer door) 3 is provided on the front surface of the main body casing 2 .

[0028] The main body casing 2 has a rectangular shape and is appropriately assembled from a plurality of steel plates, and an opening is formed on the front surface thereof.

[0029] The interior of the main body casing 2 is provided with Figure 4 Voltage control unit 4 shown. The voltage control unit 4 converts the voltage and frequency of the commercial power supply 5 into a predetermined voltage and frequency, and supplies the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com