Charging sorting device and method

A charging sequence and friction charging technology, which is applied in chemical instruments and methods, electrostatic effect separation, solid separation, etc., can solve the problem of complete selection of materials and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018]

[0019] This embodiment is a charged sorting device for sorting out the first and second materials from a mixture containing the first and second materials, and is a charged sorting device for performing secondary sorting on the mixture.

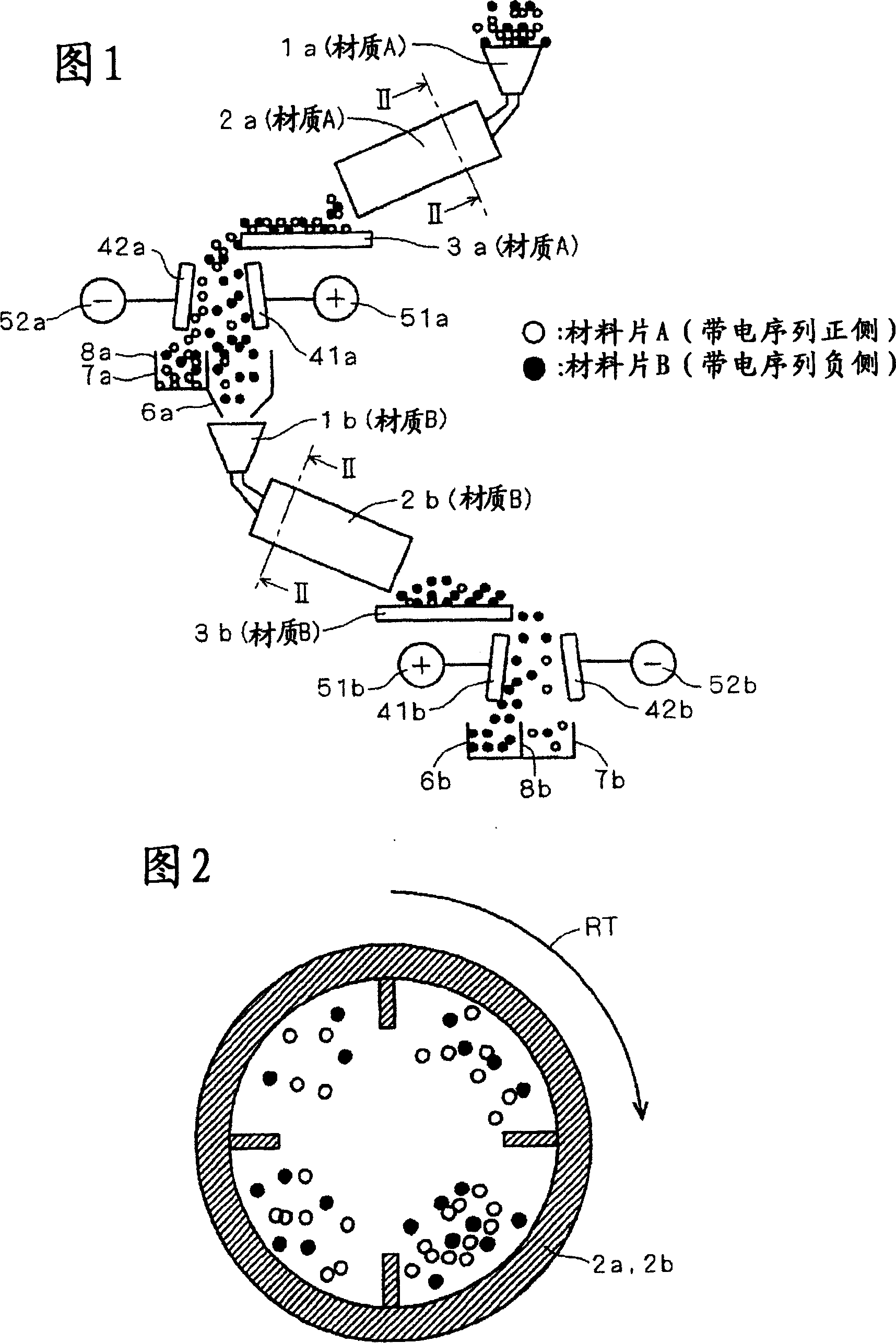

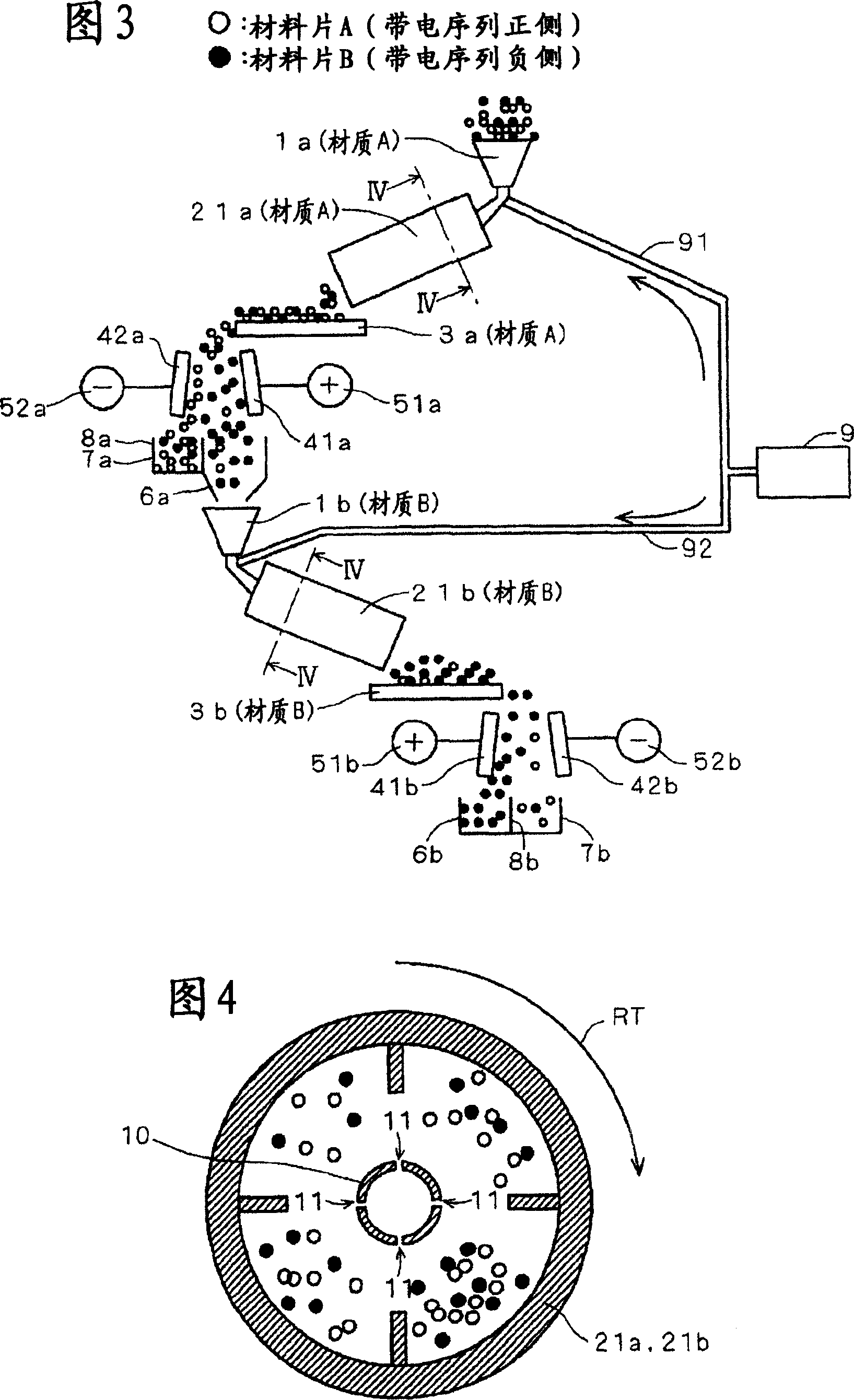

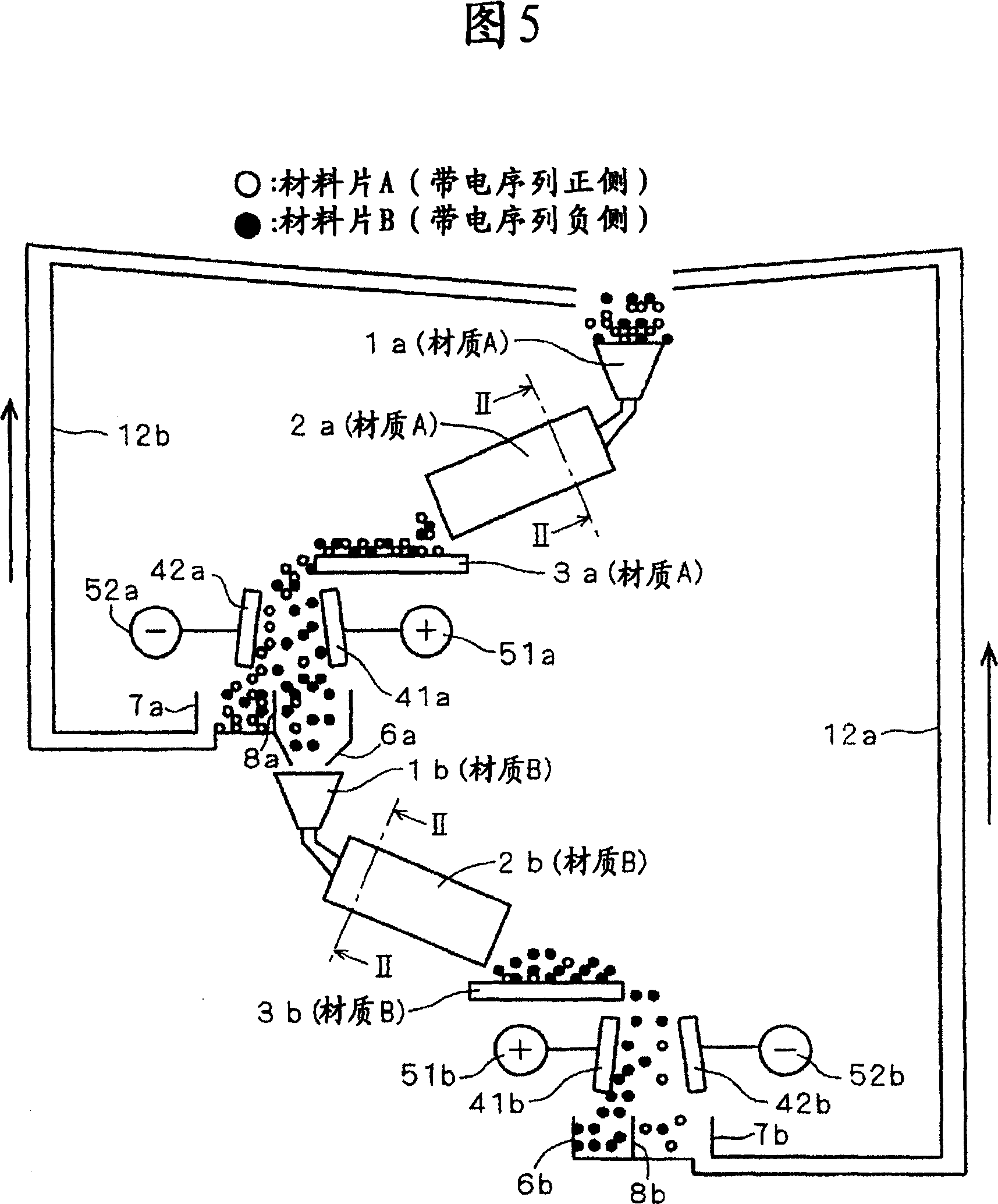

[0020] FIG. 1 is a diagram showing a charged sorting device according to the present embodiment. As shown in Figure 1, this electrified selection device has: the first stage material supply device 1a; The first stage friction electrification device 2a; The first stage electric field input device 3a; 42a; the first stage power supply 51a, 52a; the first stage recovery box 8a; the second stage material supply device 1b; the second stage friction electrification device 2b; the second stage electric field input device 3b; Set the electrodes 41b, 42b; the second stage power supply 51b, 52b; and the second stage recovery box 8b.

[0021] A mixture containing the first material (material piece A) and the second material (material piece B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com