Colorant presentation for pad printing

A technology of colorants and pad printing heads, which can be used in printing, printing machines, rotary printing machines, etc., and can solve problems such as changes in the viscosity of colorants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] overview

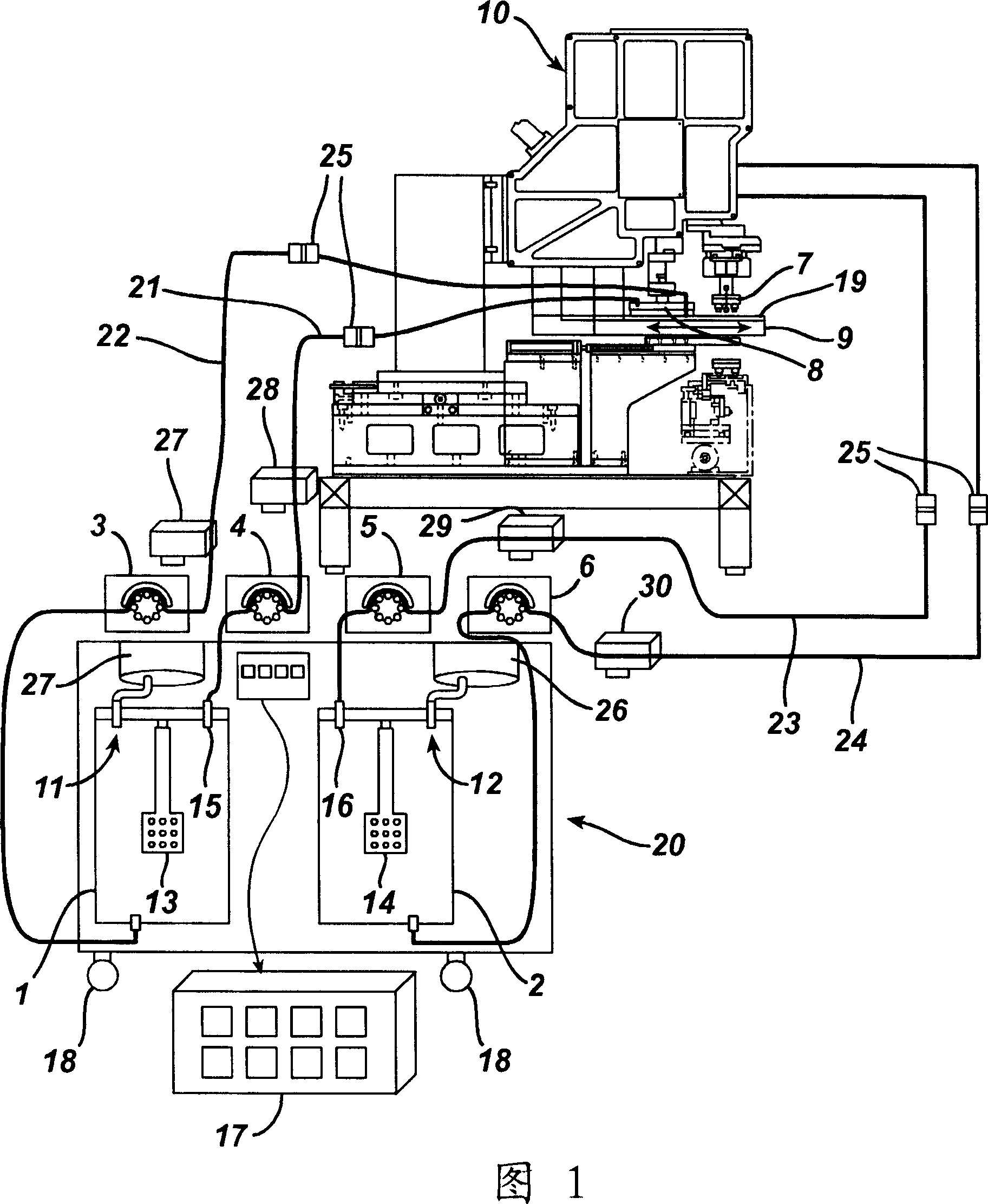

[0014] The present invention focuses on systems and methods for providing colorants, such as ink solutions, onto print cups and printing cliches for use in conjunction with pad printing. According to the present invention, a self-contained cart includes a colorant supply, an inline viscometer, a solvent supply, an automatic solvent dispenser, and a mixer for mixing solvent and colorant. The cart can be transported to the printing position on castors so that the supply and return lines can be quickly connected to the printing position, wherein the printing operation does not need to be interrupted in order to replenish the ink supply. The built-in viscometer and solution dispenser automatically maintain the colorant at the desired viscosity.

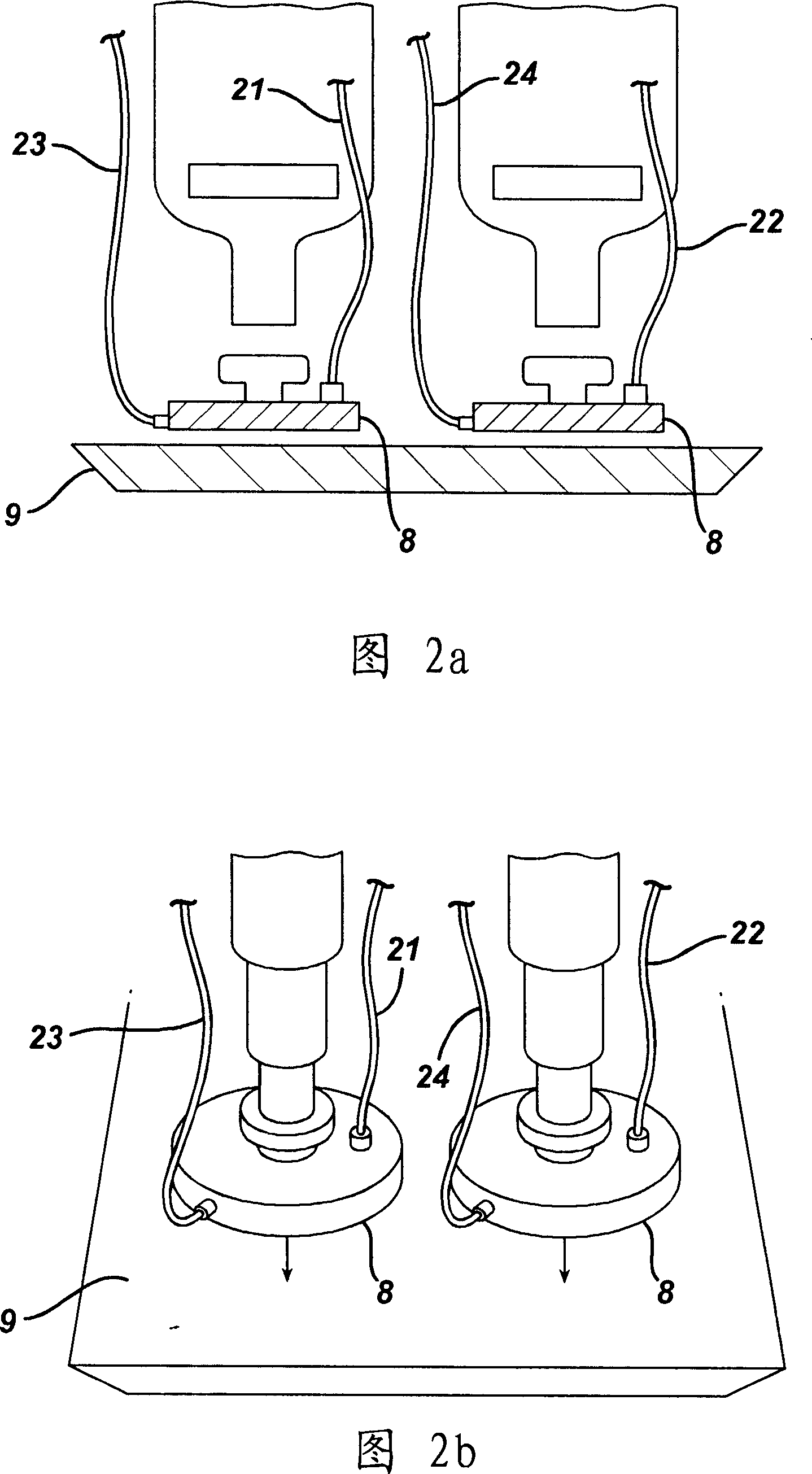

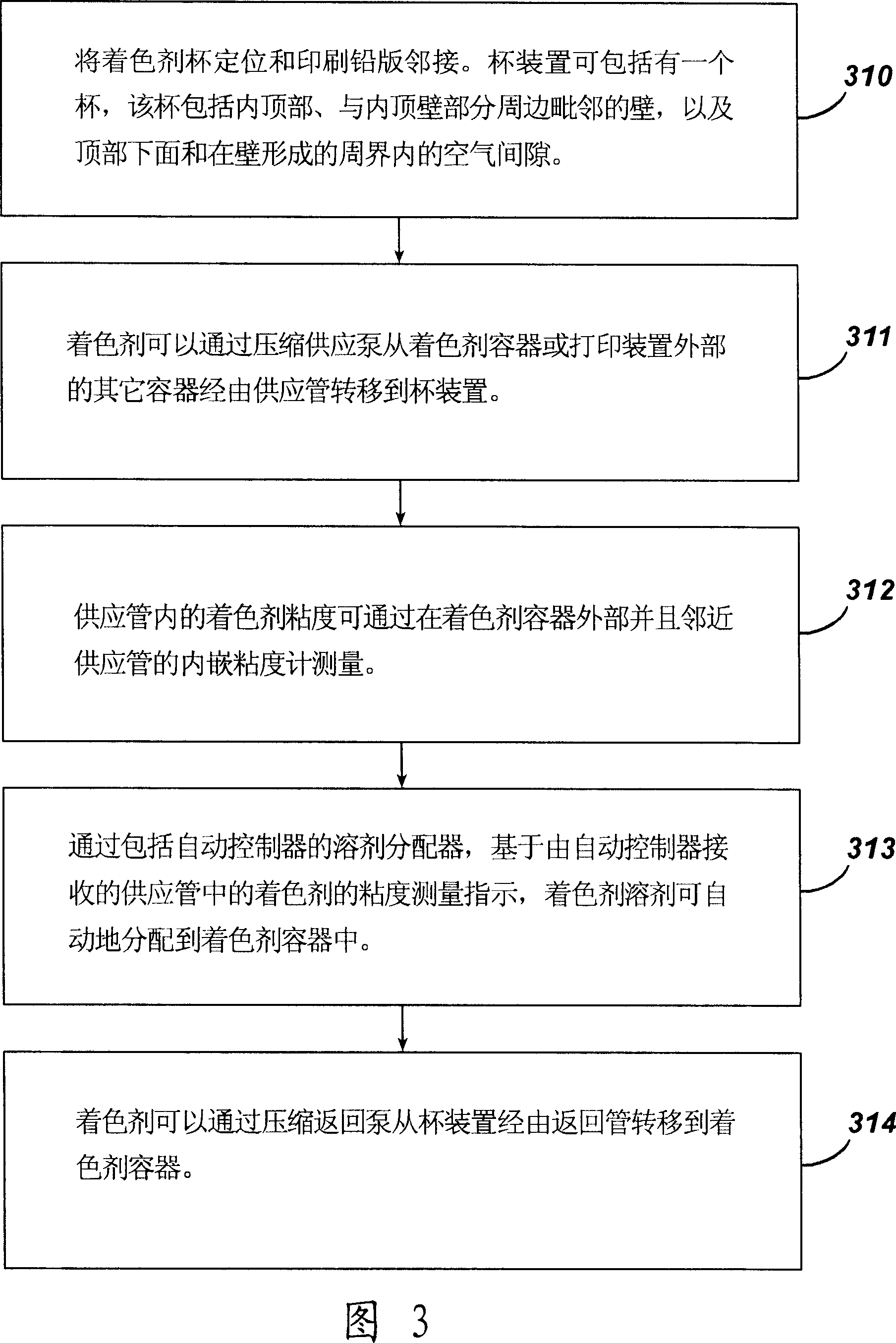

[0015] In some preferred embodiments of the present invention there is provided a method of circulating colorant in a pad printing system comprising a sealed colorant cup 8 adjacent to a cliche 9 containing colorant th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com