Drive device for refitted spinning machine or twisting machine

A technology for driving equipment and spinning machines, which is applied in the direction of continuous winding spinning machines, spinning machines, textiles and paper making, etc., and can solve the problem of difficulty in assisting driving motors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

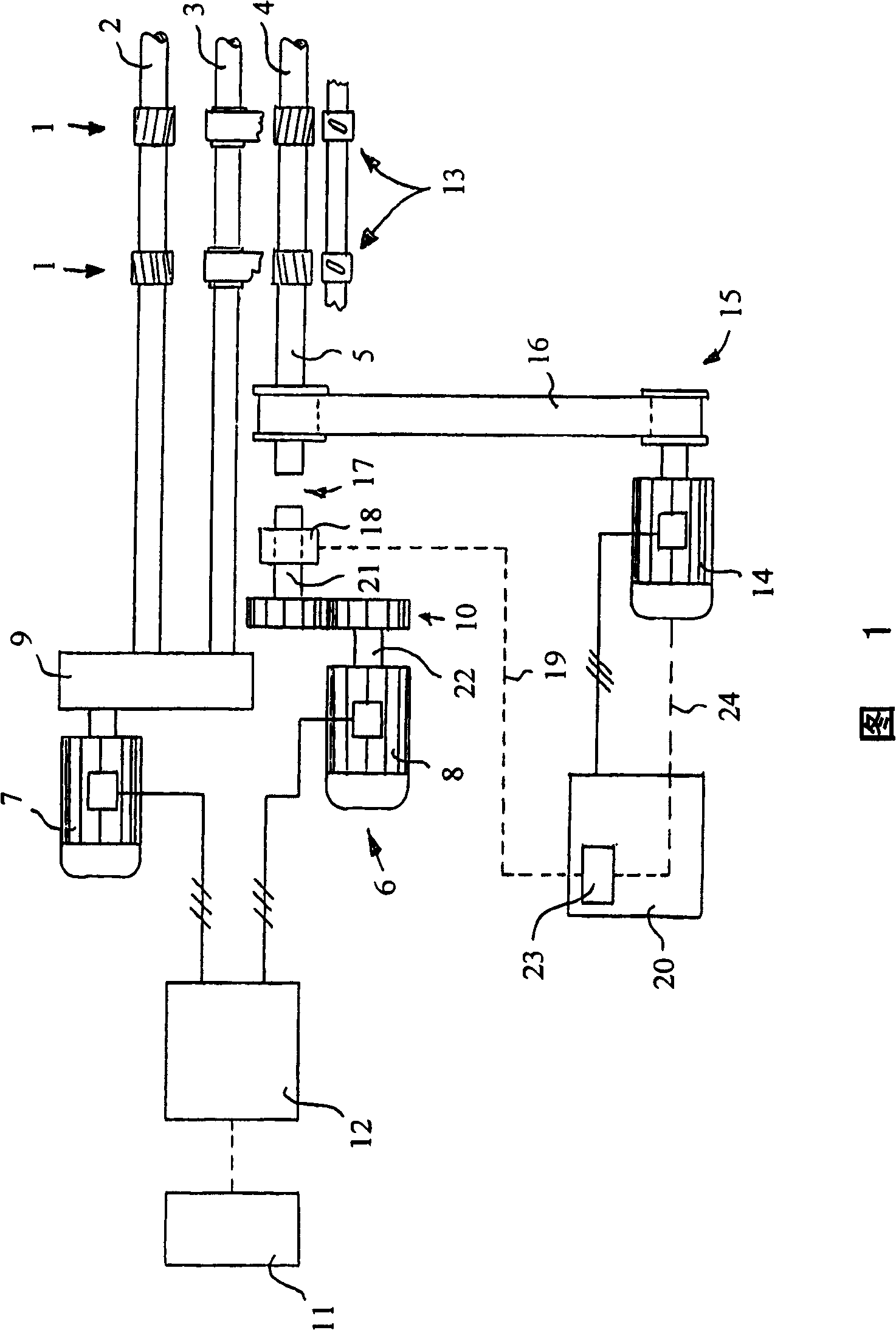

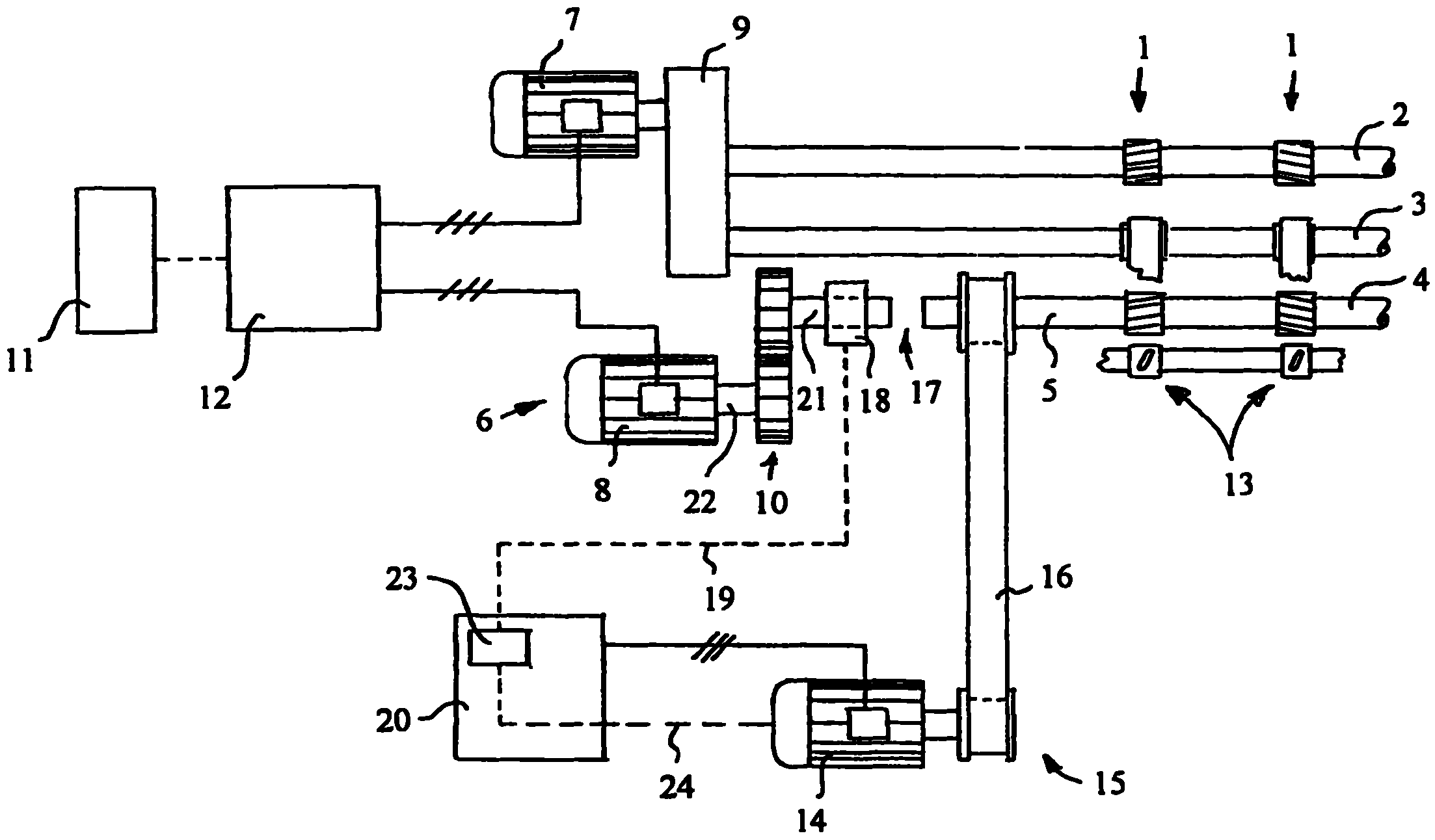

[0017] Only two such drafting units are designated here with the reference number 1 , which are likewise referred to as machine parts in this application. Such a drafting unit 1 usually consists of a plurality of roller rows 2 , 3 and 4 , wherein the last roller row in the direction of transport of the fiber material to be spun is designated as drive shaft 5 . This refers to the drafting mechanism feed roller 4 .

[0018] The roller rows 2, 3, 4 of the drafting mechanism 1 are originally driven by the original drive 6, which includes the original drive motors 7 and 8 and the transmissions 9 and 10 as main components. The original driving motor 7 drives the two roller rows 2 and 3 through the transmission device 9 . The original drive motor 8 is connected with the drive shaft 5 in the original state through the transmission device 10, and drives the drafting mechanism to supply the cylinder 4 before the machine is refitted. The primary drive motors 7 , 8 are connected to a fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com