Converter movable hood flexible ring mechanical sealing device and sealing method

A technology of mechanical sealing device and movable smoke hood, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of complex structure of sealing device, high management and maintenance cost, poor gas quality, etc., and achieve good sealing effect and reduce Construction investment, production and operation costs, and good cooling conditions

Inactive Publication Date: 2011-01-05

BEIJING MINGCHENG TECH DEV

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although the currently known nitrogen or steam sealing technology for the movable hood of the converter is an advanced technology to replace the previous water sealing technology, there are still complex structures of the sealing device, which require special gas (steam) pipeline facilities, energy consumption, and high management and maintenance costs. , the defect of poor gas quality

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

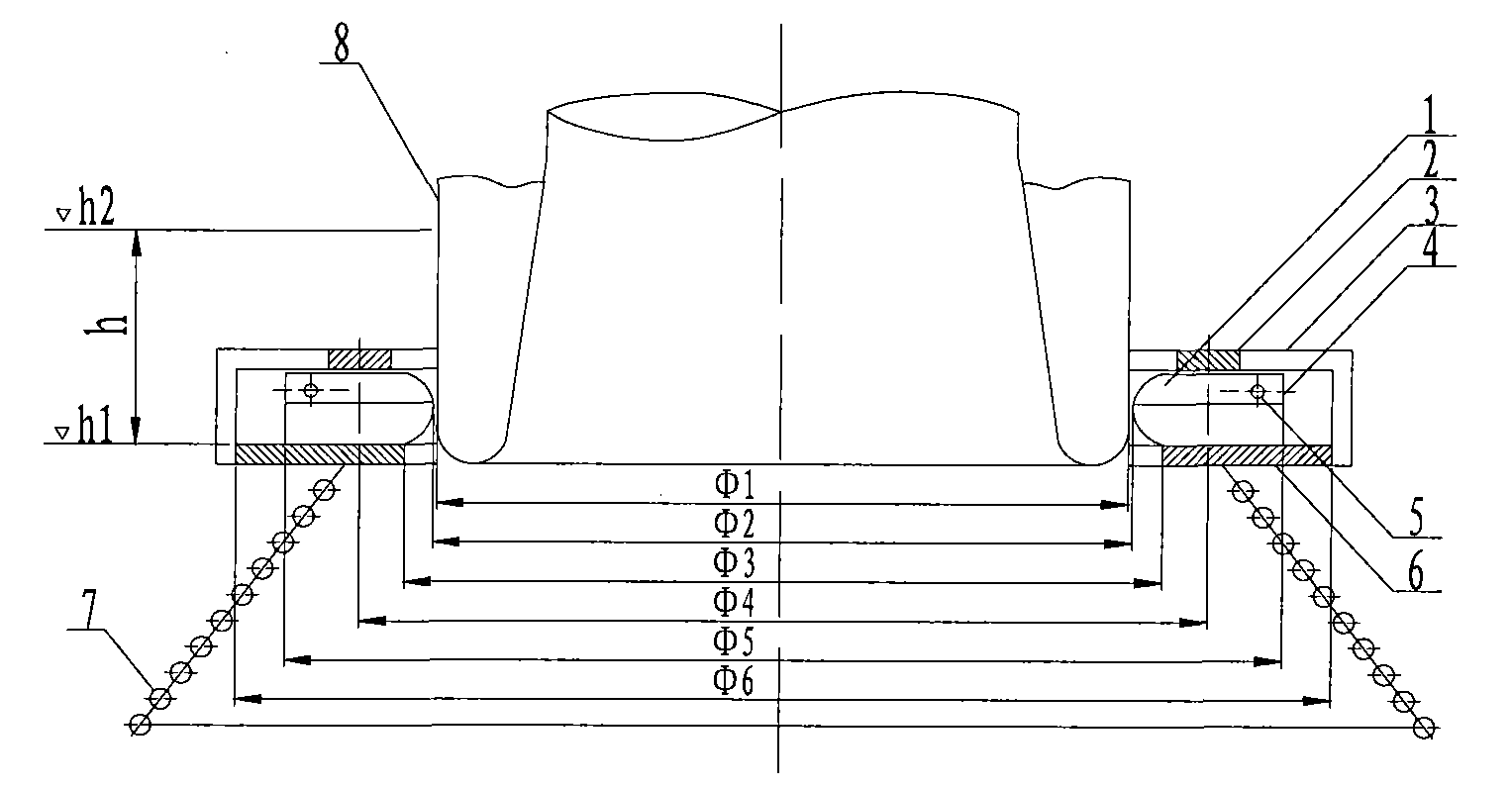

The invention discloses a converter movable hood flexible ring mechanical sealing device and a sealing method. The device comprises a fixed flue, a movable hood and a protective flange fixed on the upper end of the movable loop. The movable loop is sleeved outside the fixed flue. The protective flange is provided with a flexible ring for sealing the annular air duct between the protective flange and the fixed flue. The invention has simple structure, avoids the pipeline and valve block facility necessary for nitrogen gas or steam sealing. The invention uses cheap seal ring and simple mechanical means to solve the seal problem of the converter movable hood, thus achieving good sealing effect, reducing the construction investment and production operating cost, and improving the recovered coal gas quality.

Description

Mechanical sealing device and sealing method of flexible ring of converter movable fume hood technical field The invention relates to a sealing device and a sealing method, in particular to a flexible ring mechanical sealing device for a converter movable fume hood and a flexible ring mechanical sealing method for a converter movable fume hood. Background technique In the production of steelmaking converters, due to the requirements of gas recovery and process technology, the movable hood above the furnace mouth not only needs to be able to move up and down along the vertical section below the fixed flue of the furnace mouth, but also needs to control the movement of the movable hood within the lifting stroke. The annular gap formed between the fixed flues performs good dynamic and static sealing. Although the currently known nitrogen or steam sealing technology for the movable hood of the converter is an advanced technology to replace the previous water sealing technology...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F27D17/00C21C5/46F16J15/06

Inventor 史文锦邓刚计宝山唐武斌郭庆生

Owner BEIJING MINGCHENG TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com