Cordwood special-shaped diaphragm flexible shaft coupling

A special-shaped diaphragm flexible coupling technology, applied in elastic couplings, couplings, mechanical equipment and other directions, can solve the problems of restricting the popularization and application of traditional diaphragm couplings, and improve displacement compensation (correction correction). ) ability, avoid sudden attack damage, the effect of strict electrical insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

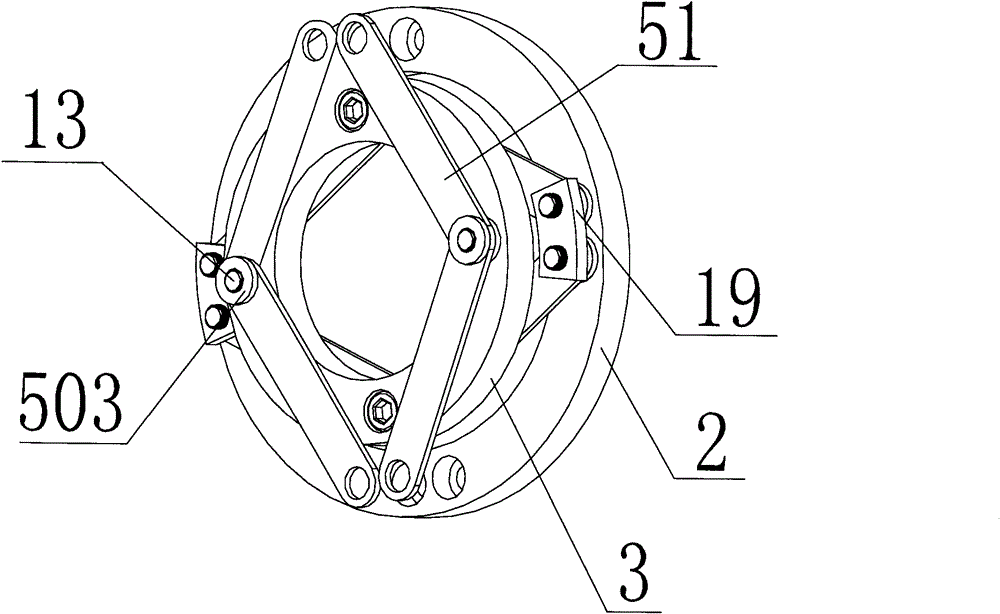

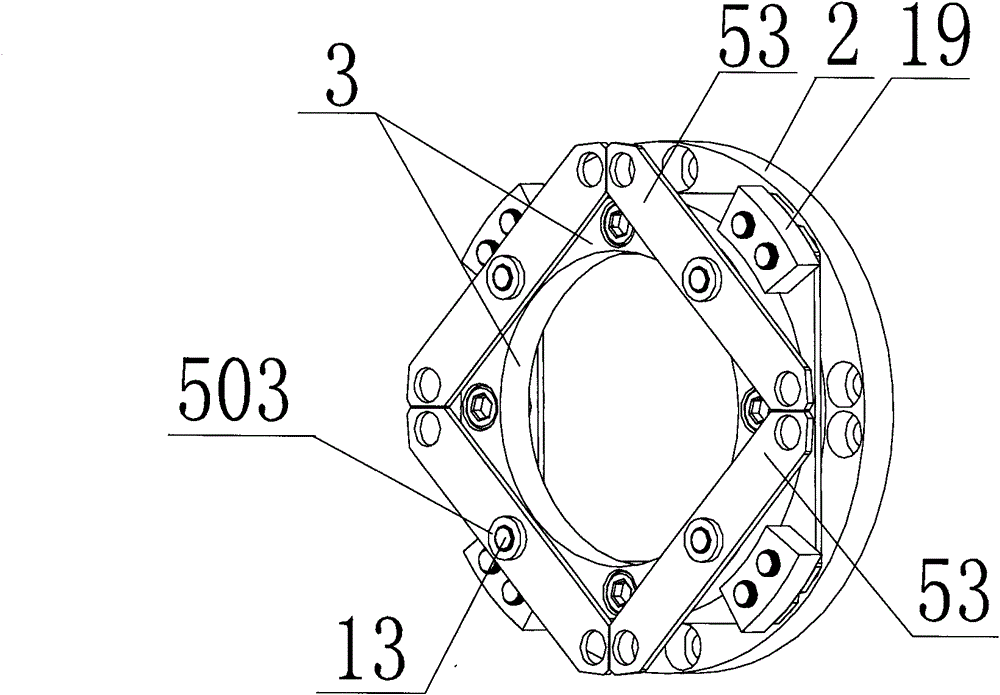

[0049] Embodiment 1: A six-unit / air-flow shielded / conventional / triangular special-shaped diaphragm coupling, such as figure 2 , Figure 14 As shown, it includes three special-shaped diaphragm assembly units 4 formed by sandwiching six single-layer triangular diaphragm chains 52 with three spacers 2 , input and output flanges 1 at both ends, and six screen nuts 16 . The special-shaped diaphragm combination unit 4 includes two single-layer triangular diaphragm chains 52 and a spacer 2 between the two single-layer triangular diaphragm chains 52, and a linkage ring is connected between every two special-shaped diaphragm combination units 4 3. The single-layer triangular diaphragm chain 52 is composed of three three-hole crescent-shaped diaphragm stacks that are closely connected end to end, and the three-hole crescent-shaped diaphragm stacks include several three-hole crescent-shaped diaphragms and several A spacer 502, the three-hole crescent-shaped diaphragm and the spacer 502...

Embodiment 2

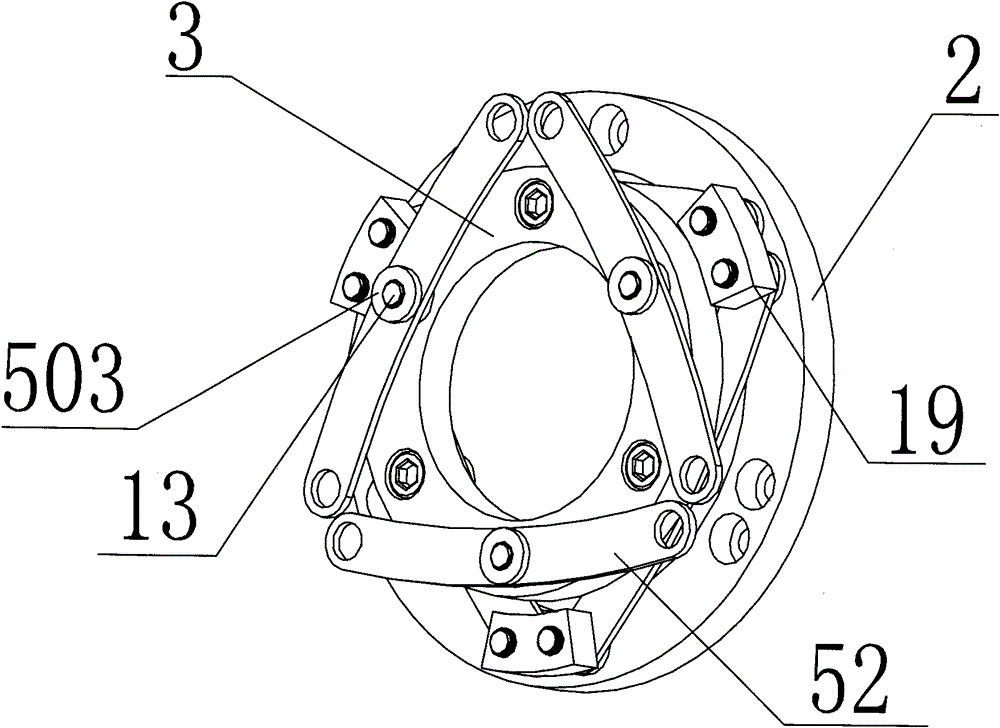

[0052] Embodiment 2: A six-unit / air-flow shielded / ultra-compact accordion type / triangular special-shaped diaphragm coupling, such as figure 2 , Figure 15 As shown, it includes three special-shaped diaphragm assembly units 4 formed by sandwiching six single-layer triangular diaphragm chains 52 with three spacers 2 , input and output flanges 1 extending inward at both ends, and six screen nuts 16 . The special-shaped diaphragm combination unit 4 includes two single-layer triangular diaphragm chains 52 and a spacer 2 between the two single-layer triangular diaphragm chains 52, and a linkage ring is connected between every two special-shaped diaphragm combination units 4 3. The single-layer triangular diaphragm chain 52 is composed of three three-hole crescent-shaped diaphragm stacks that are closely connected end to end, and the three-hole crescent-shaped diaphragm stacks include several three-hole crescent-shaped diaphragms and several A spacer 502, the three-hole crescent-sh...

Embodiment 3

[0055] Embodiment 3: A short eight-peak double square diaphragm coupling, such as Figure 11 , Image 6 , Figure 9 As shown, it includes a special-shaped diaphragm combination unit 4 formed by two eight-peak double square diaphragm chains 64 sandwiched by a spacer 2 , and an input and output flange 1 .

[0056] The eight-peak double square diaphragm chain 64 is composed of two square stepped special-shaped diaphragm chains spaced complementary to each other; Staggered end-to-end overlapping connection composition, such as Figure 8 As shown; the two-hole special-shaped diaphragm laminate 60 includes several two-hole special-shaped diaphragms 601 and several spacers 502, and the two-hole special-shaped diaphragm 601 and spacer 502 are formed by a two-hole special-shaped diaphragm 601 A spacer 502 is sandwiched or a plurality of two-hole special-shaped diaphragms 601 are sandwiched by a spacer 502 to form a two-hole special-shaped film laminate 60 . The two-hole special-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com