Patents

Literature

36results about How to "Avoid the danger of vandalism" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

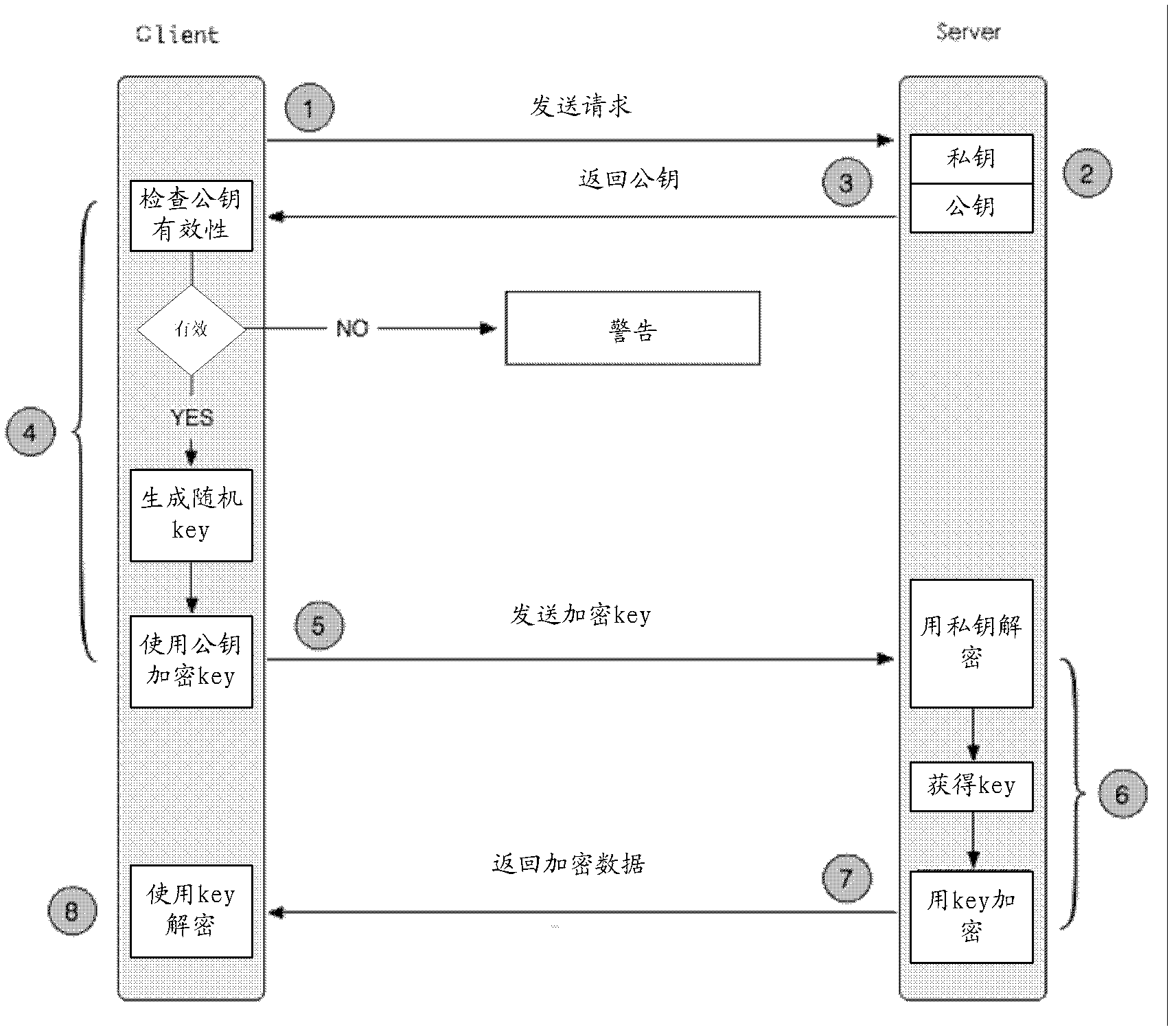

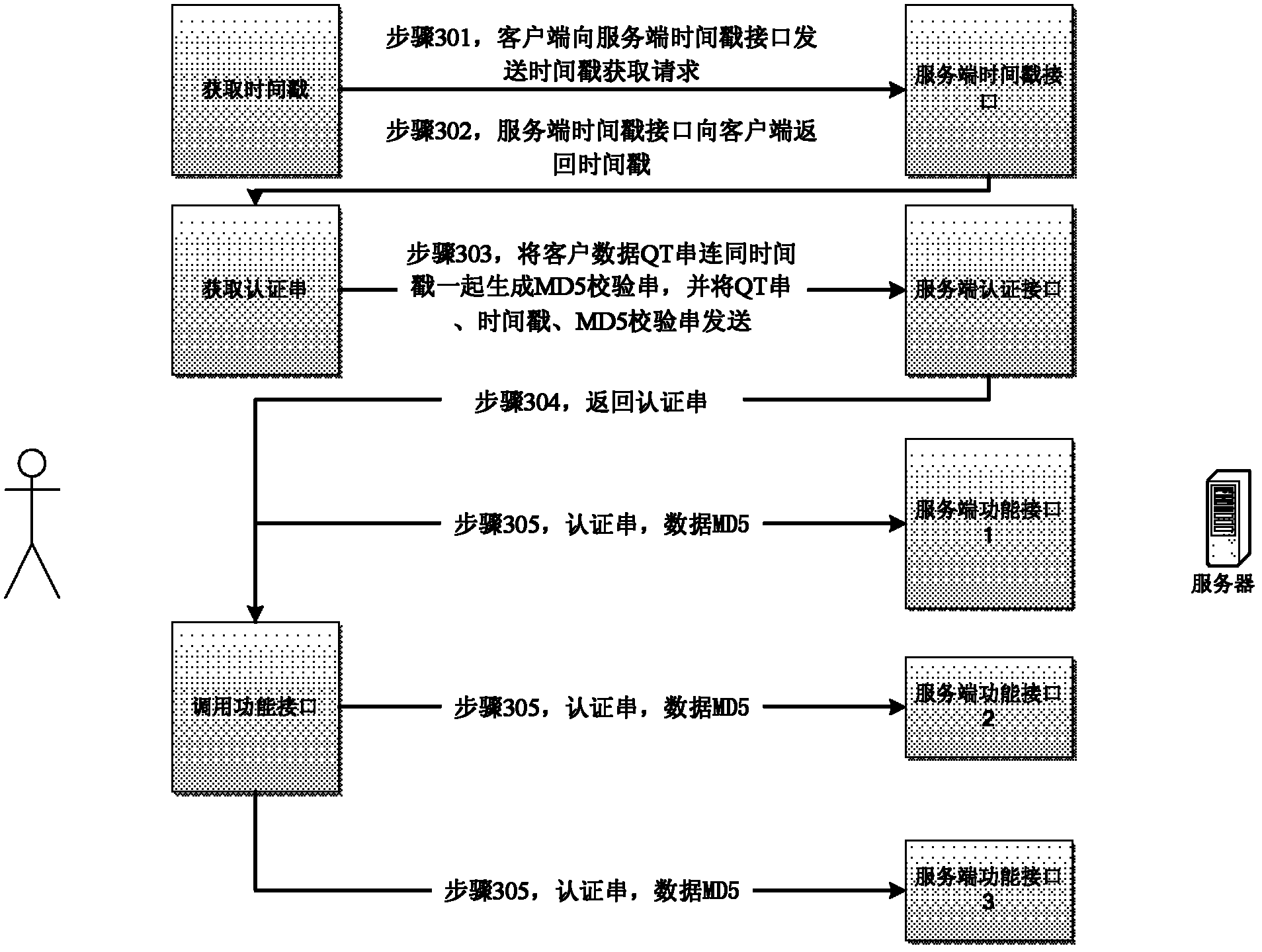

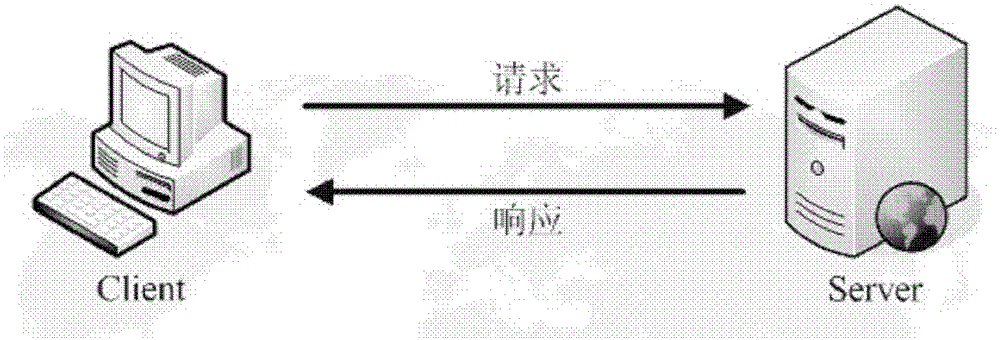

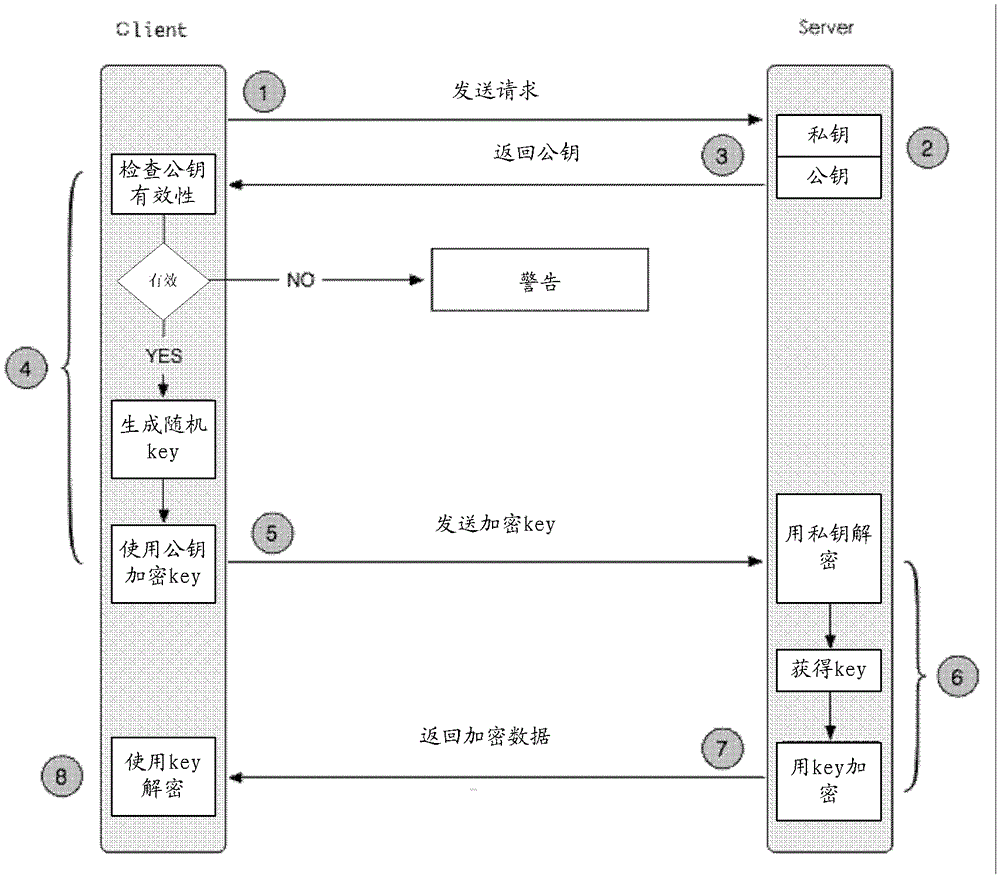

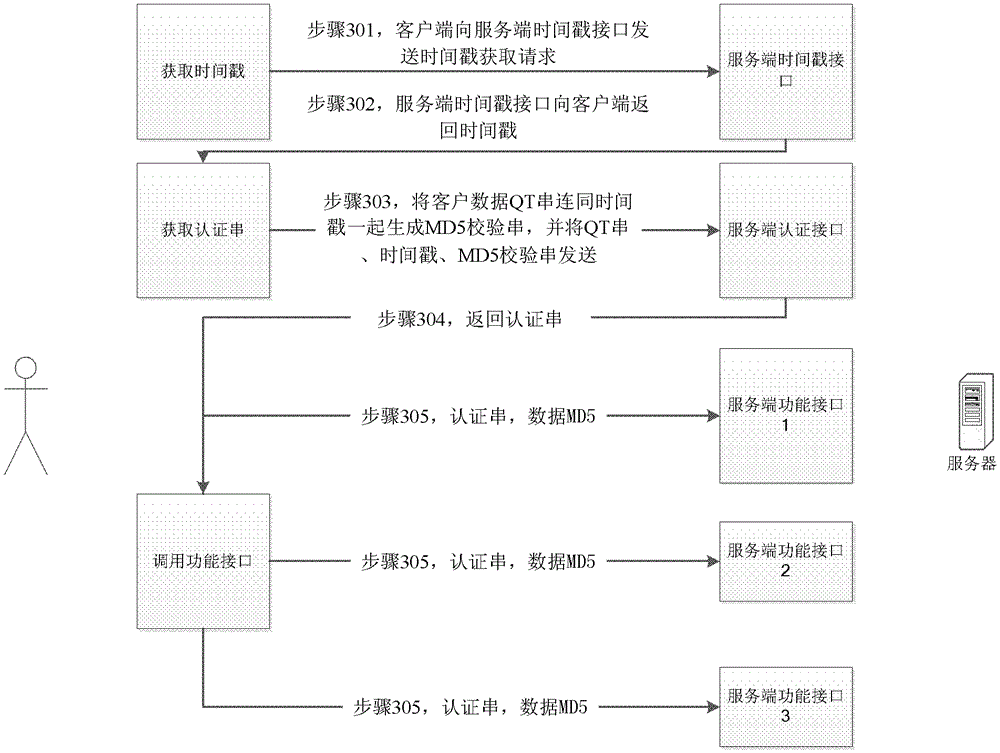

Data interaction method, client and server

ActiveCN102624740APrevent tamperingAvoid the danger of vandalismUser identity/authority verificationTimestampHypertext Transfer Protocol over Secure Socket Layer

The invention provides a data interaction method, a client and a server, so as to solve the problems of requested replaying and client computer safety that cannot be solved by adopting HTTPS (Hyper Text Transfer Protocol Secure) technique. The method comprises the following steps: obtaining a timestamp from a service terminal; sending the first identifying information of a user, the timestamp and verifying data generated according to the first identifying information of the user and the timestamp to the service terminal; obtaining certified data encrypted by the service terminal, wherein the certified data comprises the encrypted data generated for the timestamp and second identifying information of the user; and using the certified data to access the service terminal. According to the method provided by the invention, HTTPS encryption and improved MD5 are used together while the encryptions at the client and service terminal are adopted, so that the possibility of distorting and falsifying data at 'end' and 'path' is efficiently avoided. Besides, the timeliness control is performed on interface calling by using effective time through the timestamp, so that the data damage risk caused by recording and largely replaying a user request is efficiently avoided.

Owner:BEIJING QIHOO TECH CO LTD

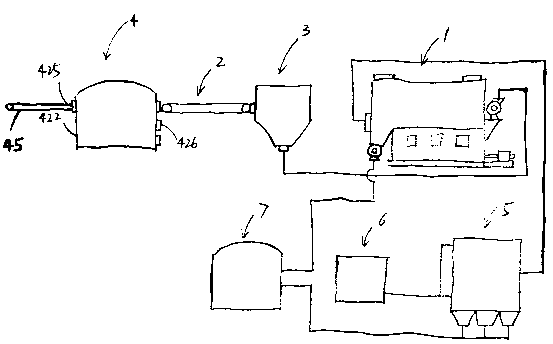

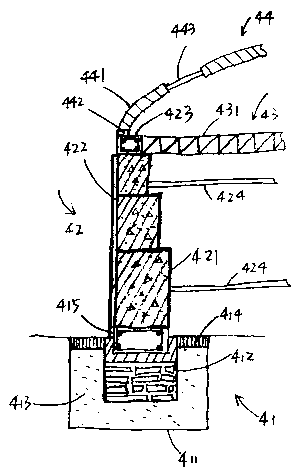

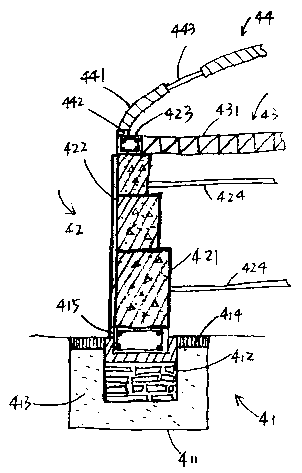

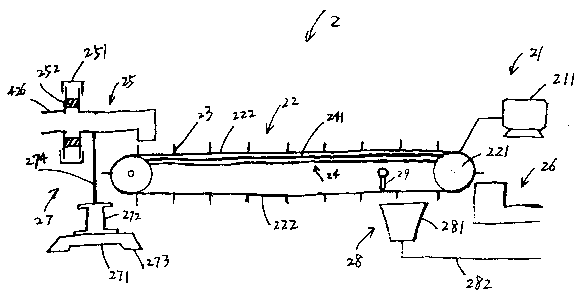

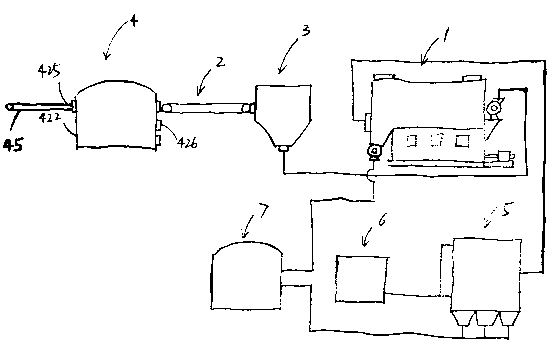

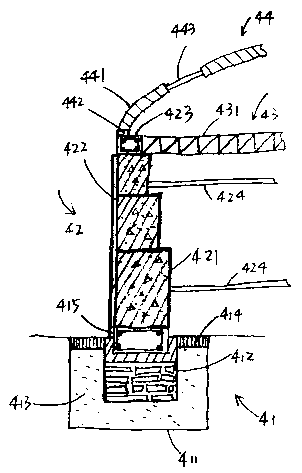

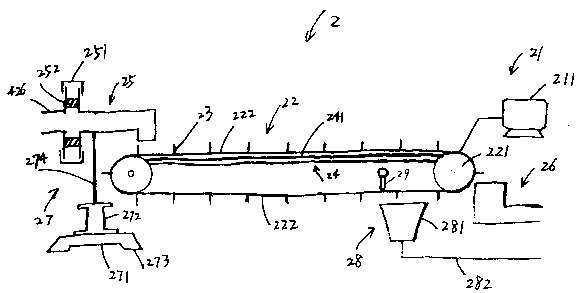

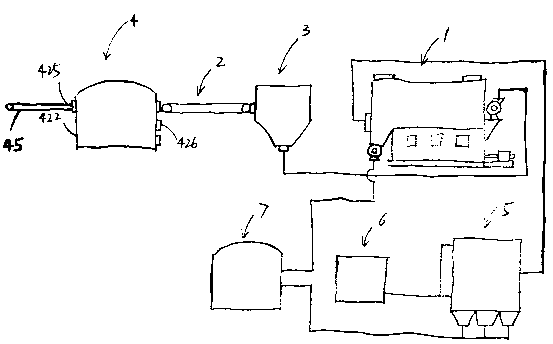

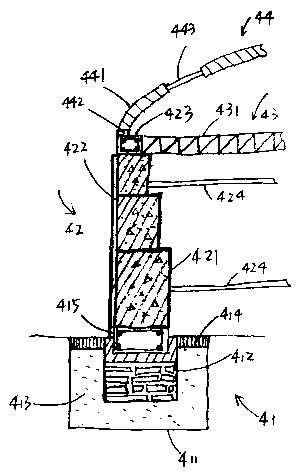

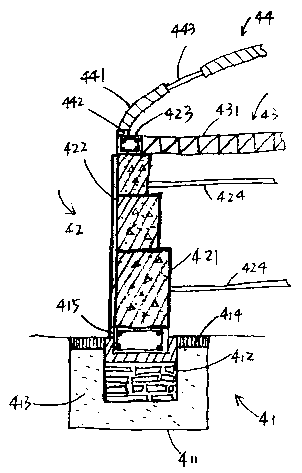

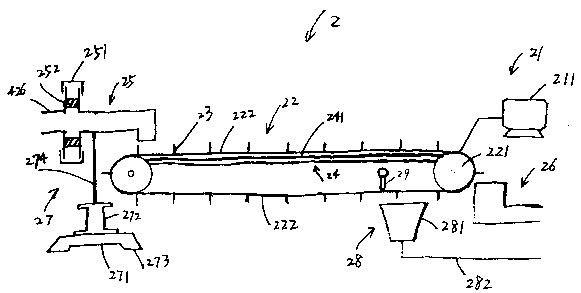

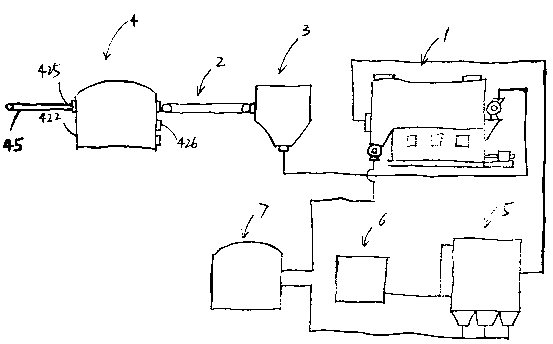

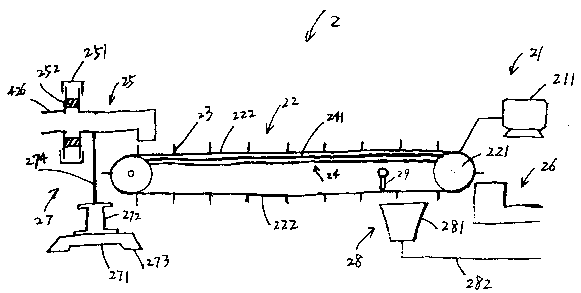

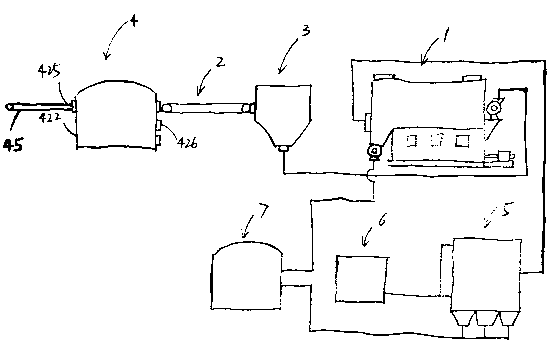

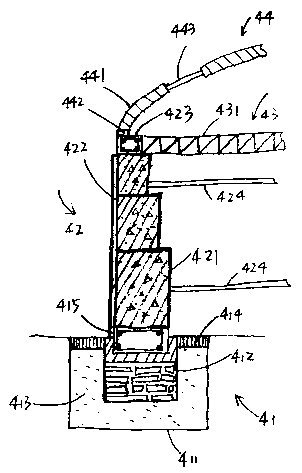

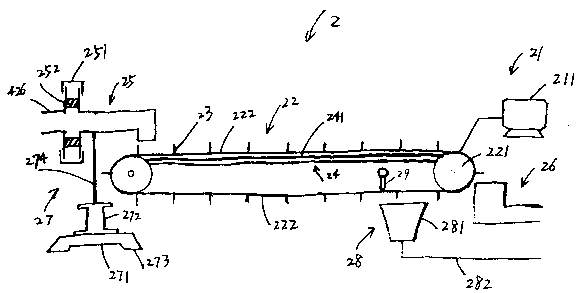

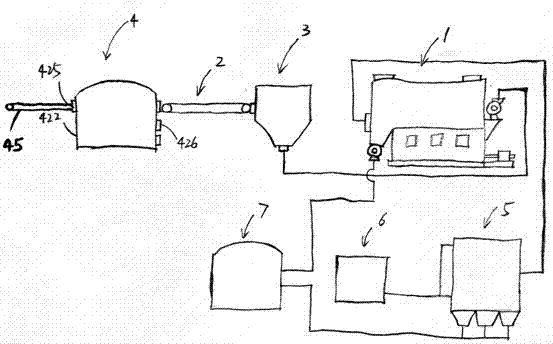

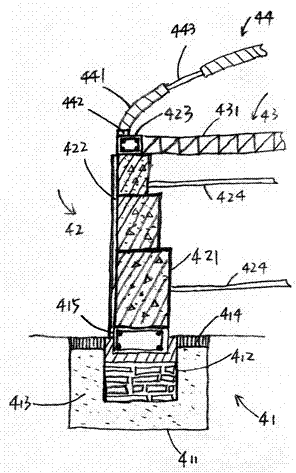

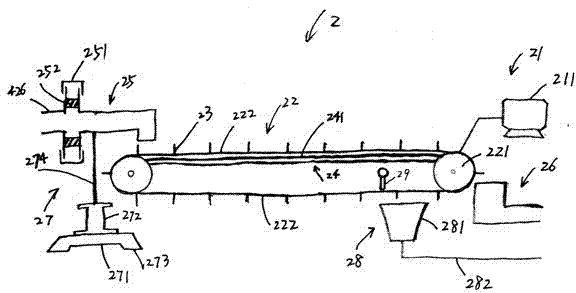

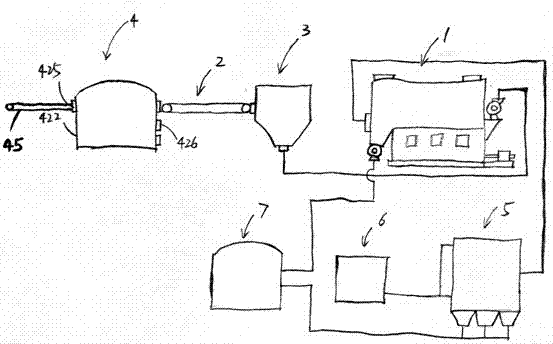

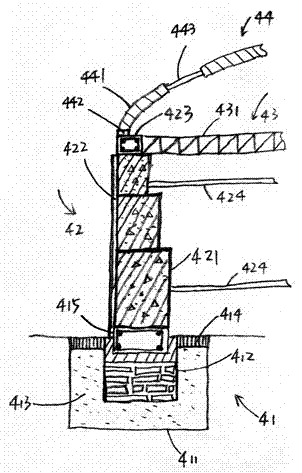

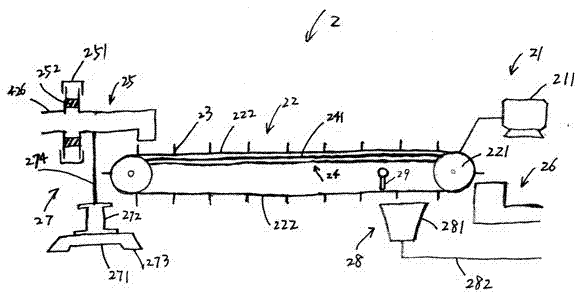

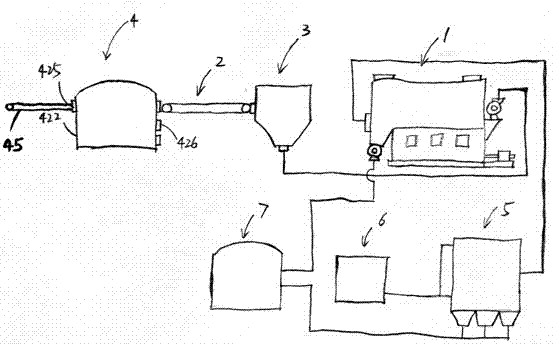

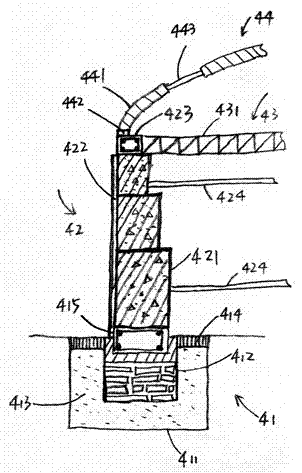

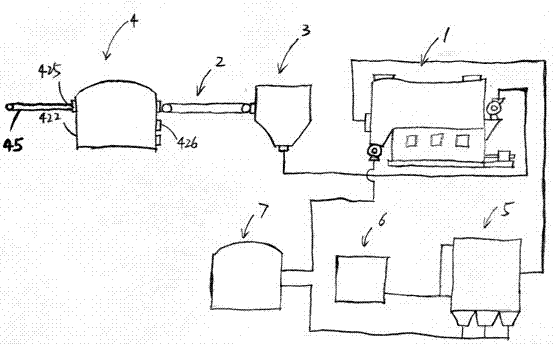

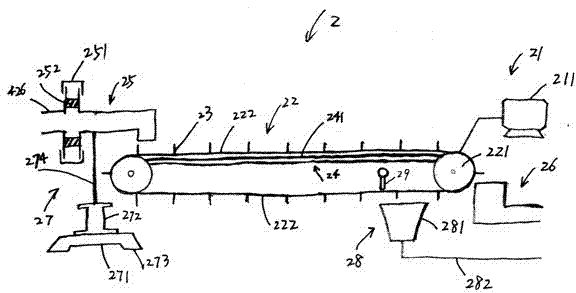

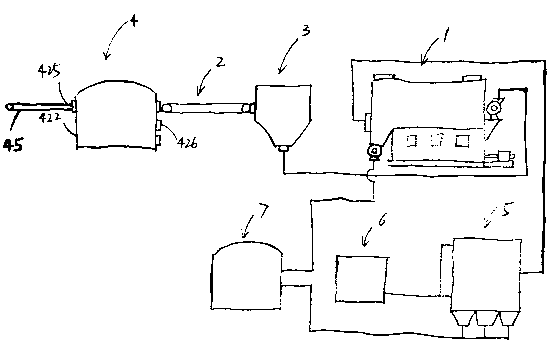

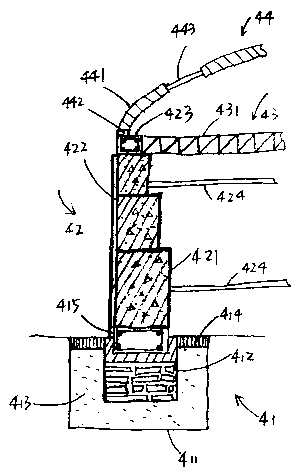

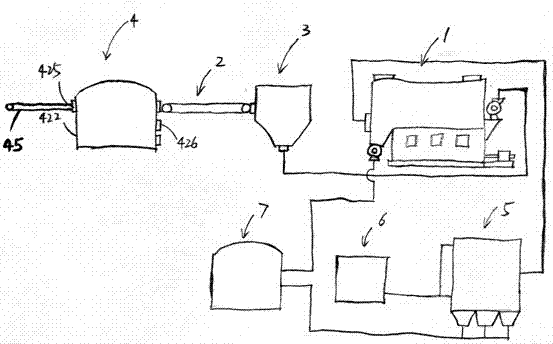

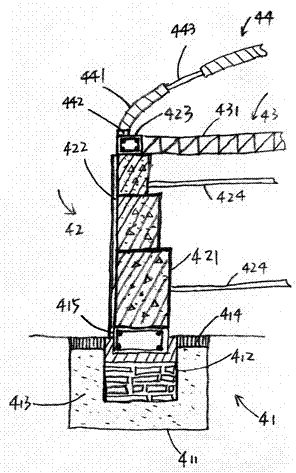

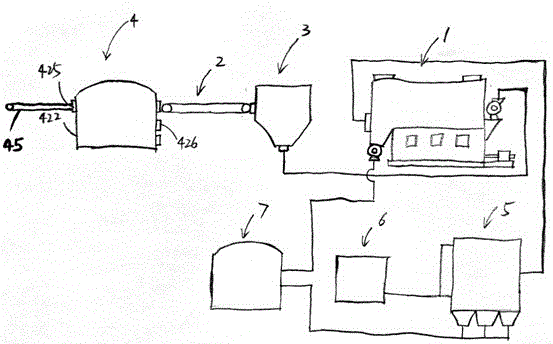

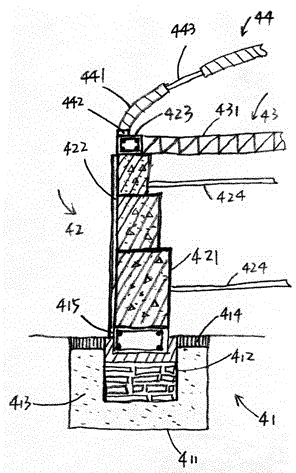

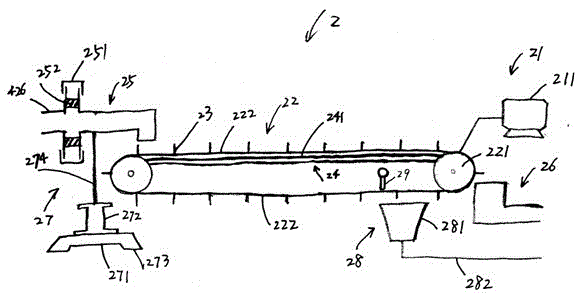

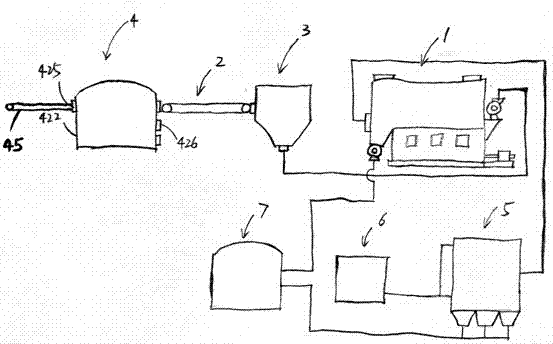

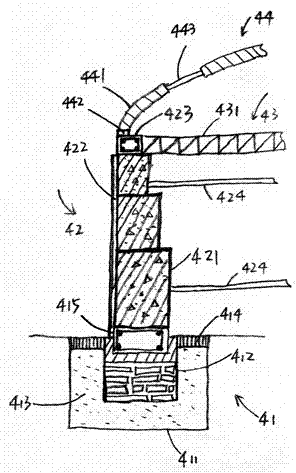

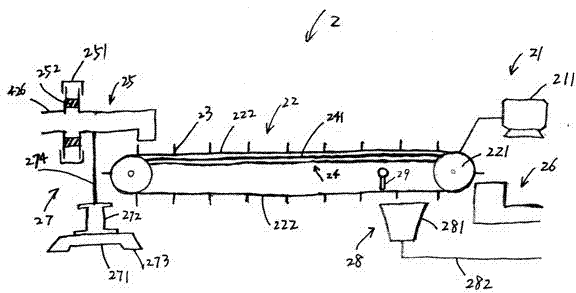

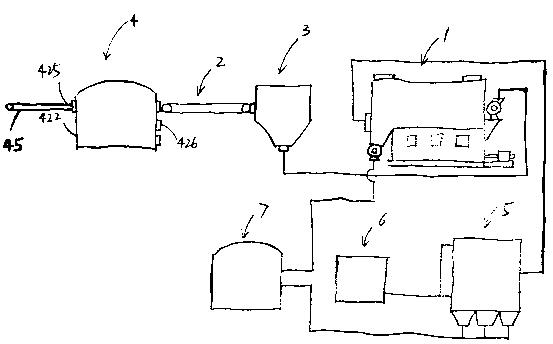

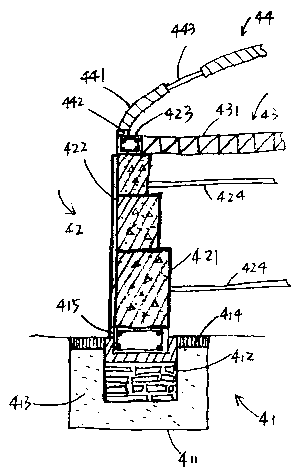

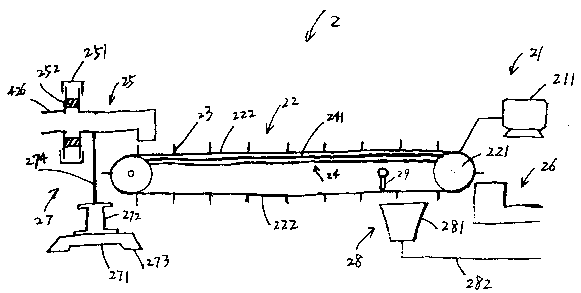

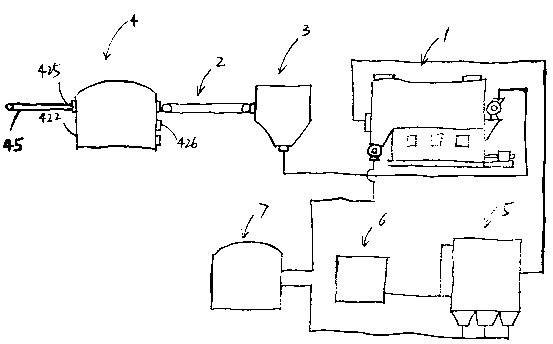

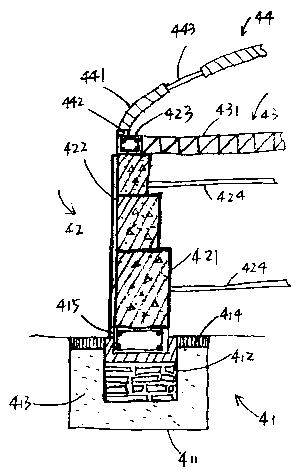

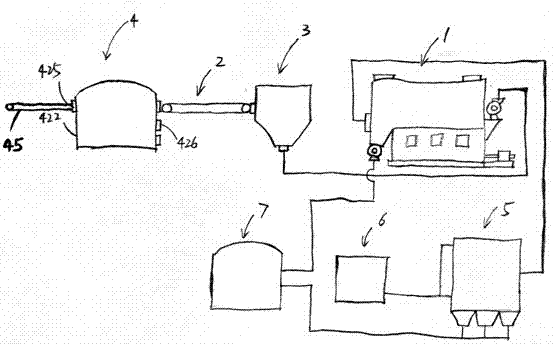

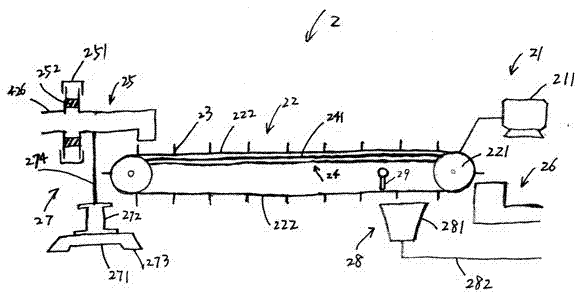

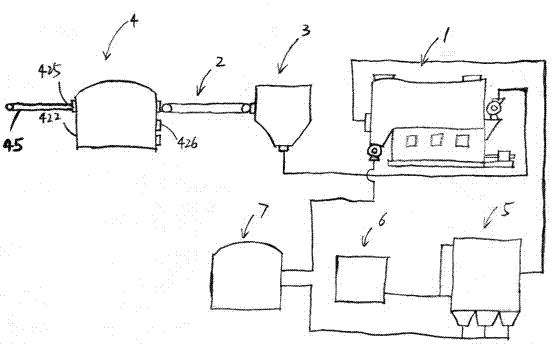

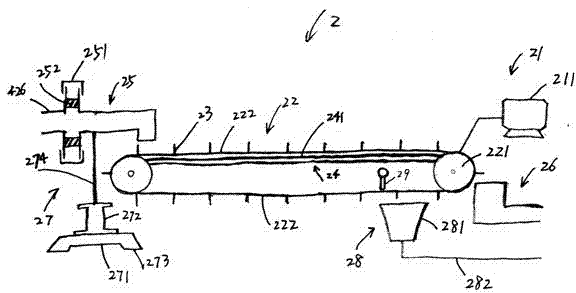

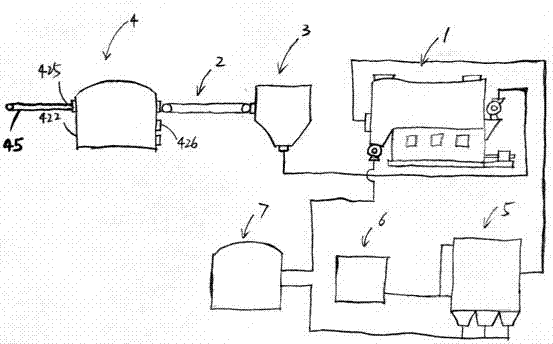

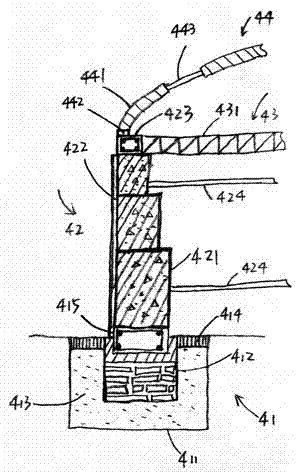

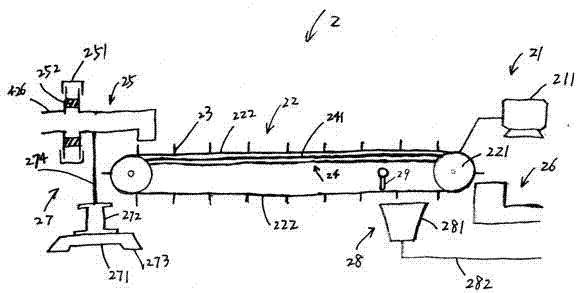

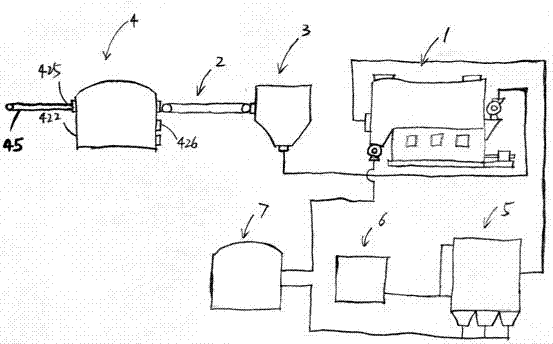

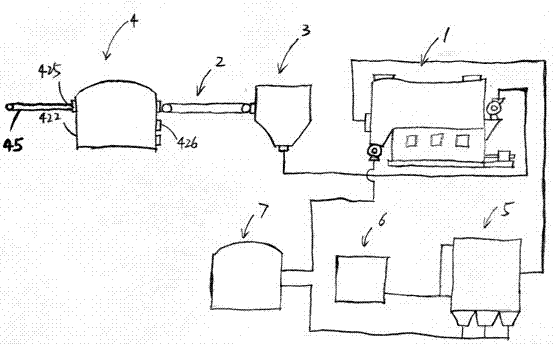

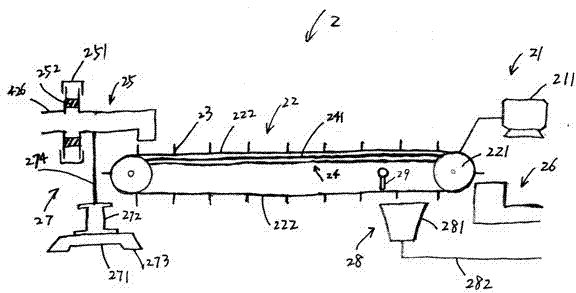

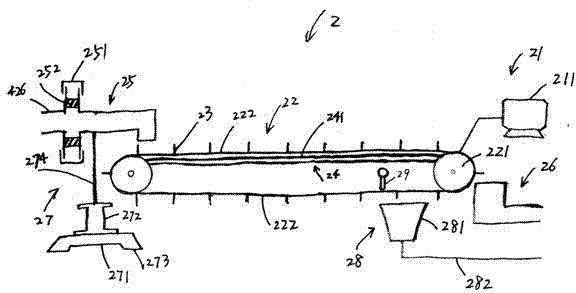

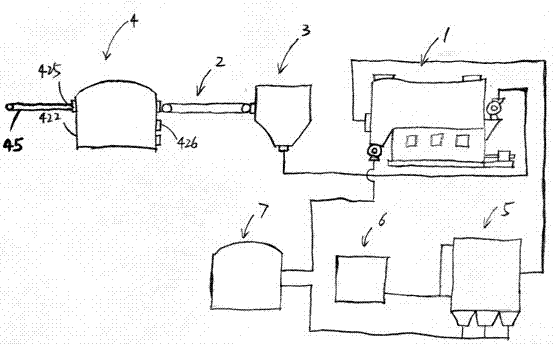

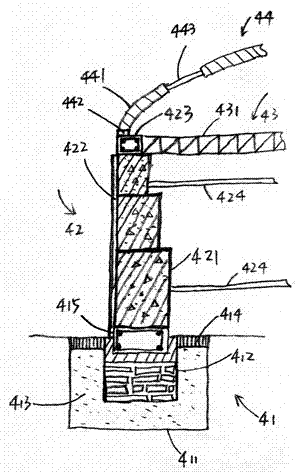

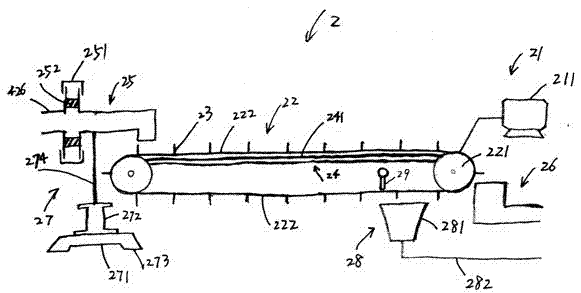

Production line used for drying coal slime

ActiveCN103134289AImprove stabilityLow costDrying machines with non-progressive movementsPreliminary solid treatment for dryingLow noiseProduction line

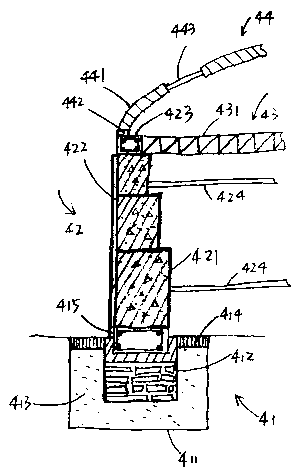

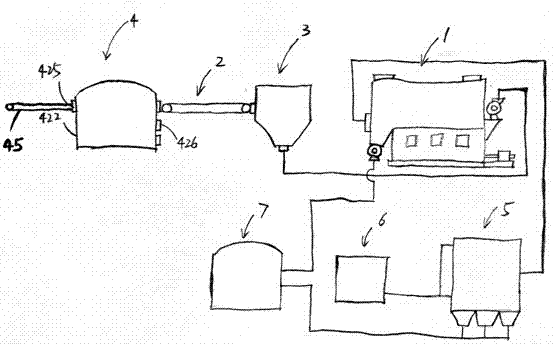

The invention relates to a production line used for drying coal slime. The production line used for drying the coal slime is characterized by comprising a coal slime raw material repository, a scraper conveyor, a preparatory material storage bin, a coal slime drier, a coal dust gas dusting machine, a gas recycling device and a finished product repository, wherein reinforcing ribs arranged in a drying cabin of the coal slime drier of the production line can guarantee no deformation of the cabin body of the drying cabin in a high pressure environment; and thermal insulation cotton among the reinforcing ribs guarantees heat loss of the drying cabin to be as low as possible, realizes the energy-saving purpose and lowers the production cost. The production line used for drying the coal slime has the advantages of low energy consumption, low noise, strong structure stability, high processing efficiency, low equipment cost, strong equipment adaptability, no material blockage phenomenon, few production faults, low manufacturing cost and resource economization.

Owner:YUNNAN ZHONGYI DINGDONG ENERGY TECH DEV

Drying treatment system of slurry

ActiveCN103134284AImprove stabilityLow costDrying machines with non-progressive movementsPreliminary solid treatment for dryingLoad torquePulp and paper industry

The invention relates to a drying treatment system of slurry. The drying treatment system is characterized by comprising a slurry raw material storing warehouse, a scraper conveying machine, a prepared material cabin, a slurry drying machine, a coal dust gas dusting machine, a gas recycling device and a finished product storing warehouse. A material raising shaft of the slurry drying machine in the treatment system is made of high-temperature-resisting materials and adopts a loading torque loop, so that the material raising shaft cannot deform under high-temperature, high-speed and large-torque operation, the material raising capability and the torque bearing capability of the material raising shaft are greatly improved, and the material raising efficiency and the working stability are greatly improved. The drying treatment system has the advantages of being low in energy consumption, low in noise, strong in structural stability, high in processing efficiency, low in device cost, strong in device adaptation, free of blocking, less in production failure, low in manufacture cost, and capable of saving resources.

Owner:YUNNAN ZHONGYI DINGDONG ENERGY TECH DEV

Production line used for drying coal slime

ActiveCN103134290AImprove stabilityLow costDrying machines with non-progressive movementsPreliminary solid treatment for dryingLow noiseThermal insulation

The invention relates to a production line used for drying coal slime. The production line used for drying the coal slime is characterized by comprising a coal slime raw material repository, a scraper conveyor, a preparatory material storage bin, a coal slime drier, a coal dust gas dusting machine, a gas recycling device and a finished product repository, wherein an air speed adjusting valve which is convenient to control a flow speed of hot air in the coal slime drier is arranged at an air outlet of a blower of the coal slime drier of the production line, and a temperature control device which is convenient to control the temperature of the hot air flowing into the coal slime drier is arranged in a hot air inlet pipe, so that heat energy waste is avoided; and thermal insulation cotton is sleeved outside the hot air inlet pipe, so that heat loss is further reduced, and production cost is saved. The production line used for drying the coal slime has the advantages of low energy consumption, low noise, strong structure stability, high processing efficiency, low equipment cost, strong equipment adaptability, no material blockage phenomenon, few production faults, low manufacturing cost and resource economization.

Owner:YUNNAN ZHONGYI DINGDONG ENERGY TECH DEV

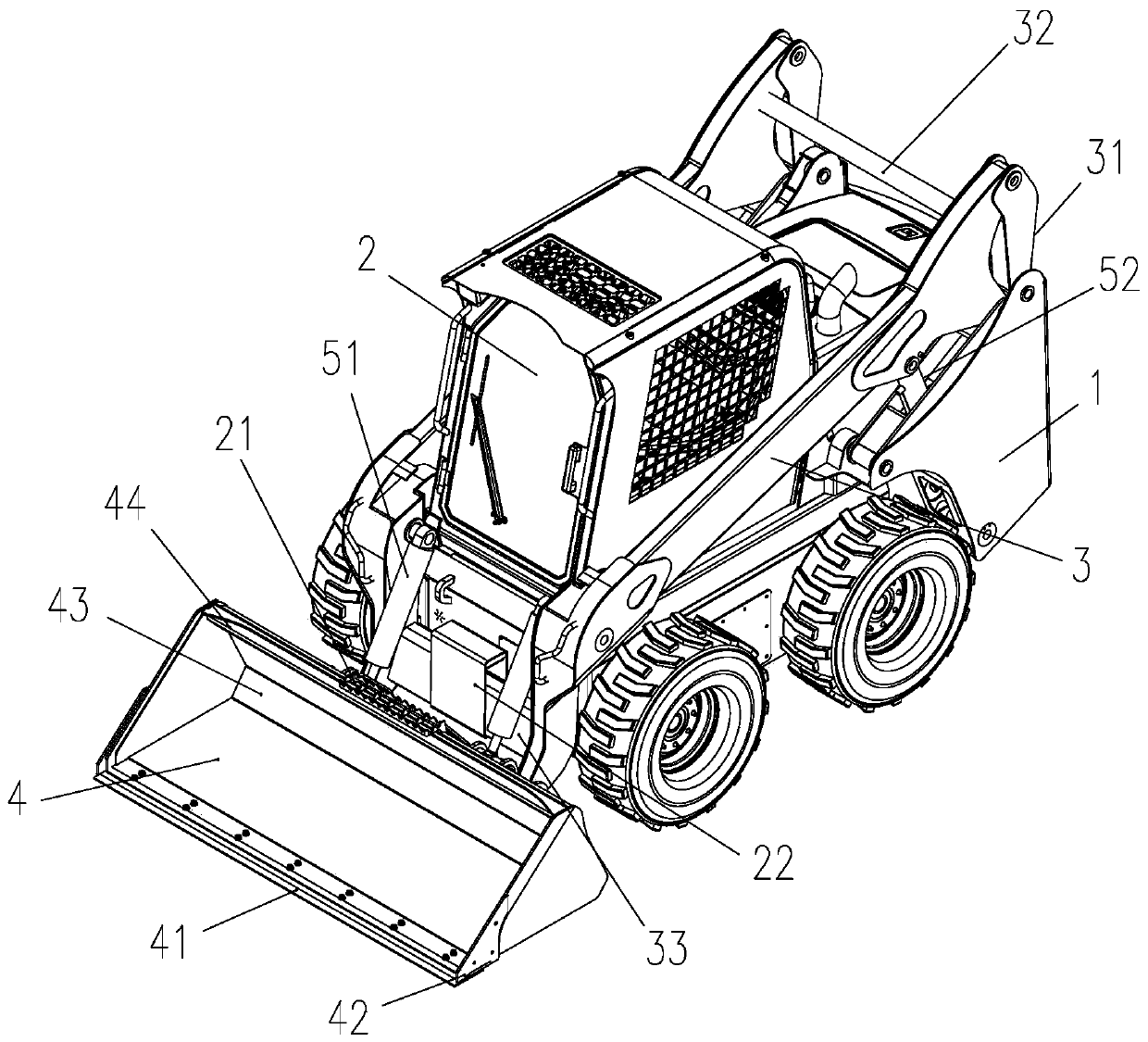

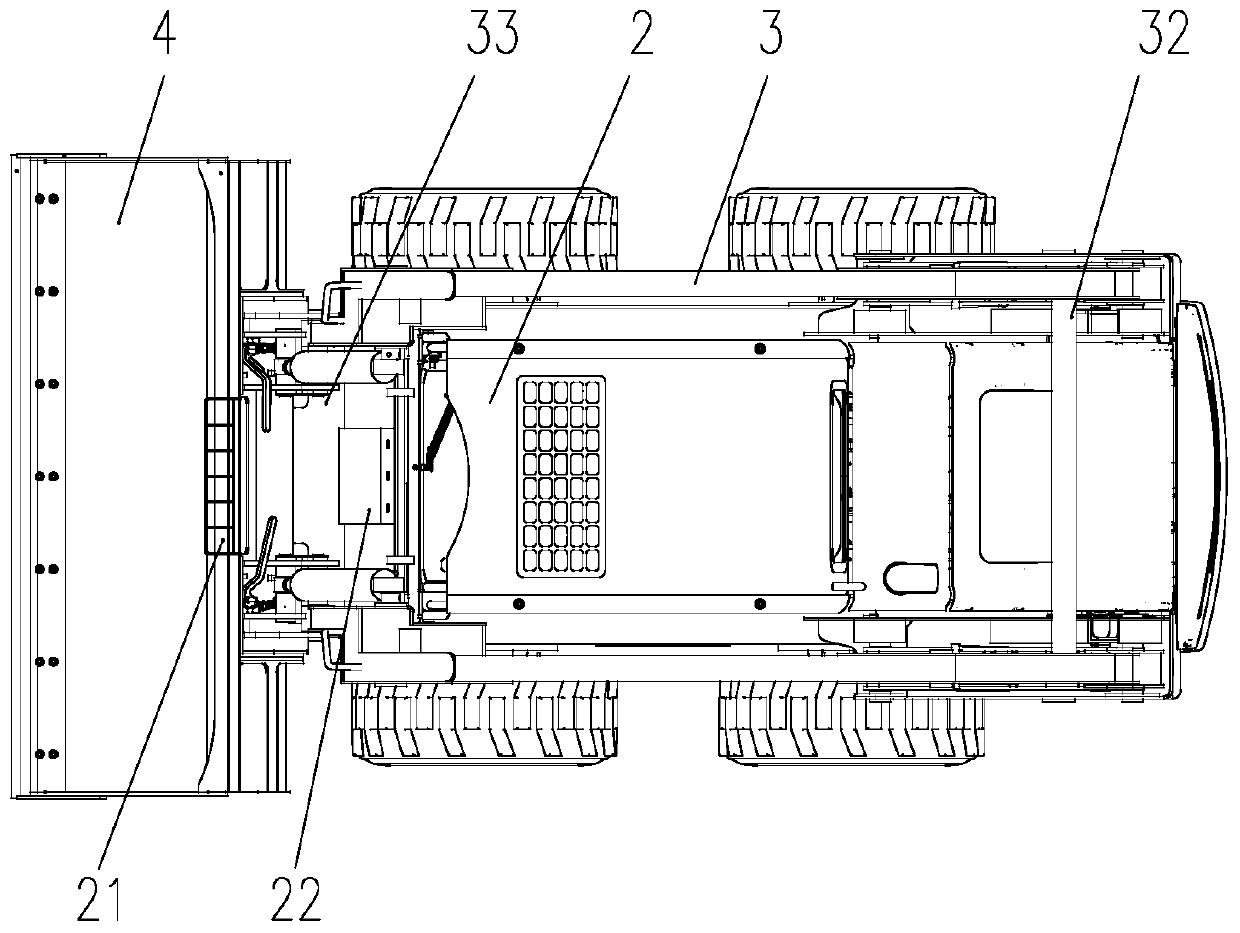

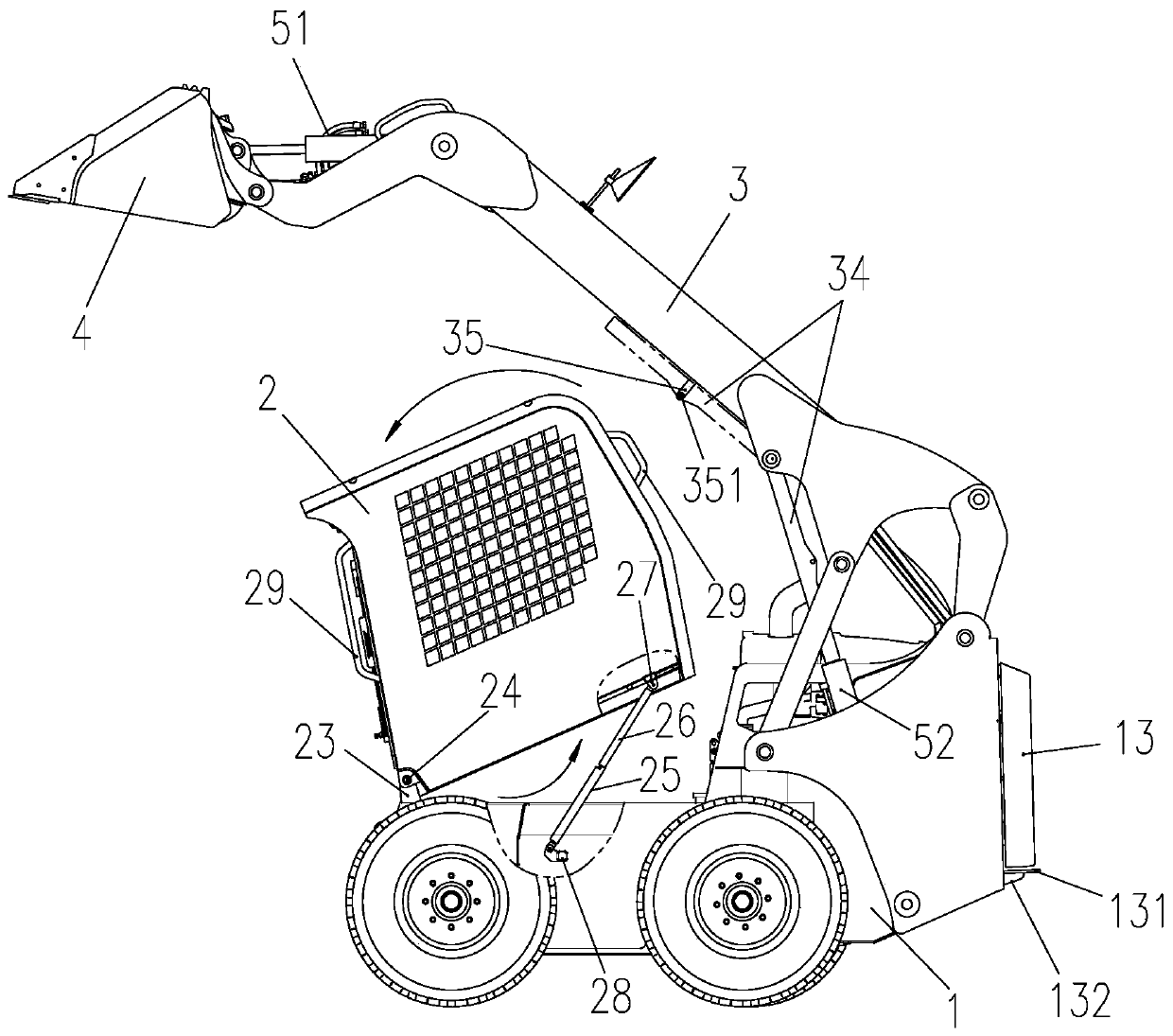

Sliding loading machine

PendingCN110984262ASmall working capacityImprove work performanceMechanical machines/dredgersClassical mechanicsMachine

The invention discloses a sliding loading machine. A chassis frame, a cab, a main beam and a bucket are included. The chassis frame and a walking system are assembled to form a moving chassis of the sliding loading machine, and a power system of the sliding loading machine is assembled to the tail of the chassis frame. The cab is arranged at the front portion of the chassis frame in an overturnedmanner. The cab is horizontally borne on the chassis frame when a telescopic supporting rod is in a contraction state and forwards overturns when the telescopic supporting rod is in a stretching-out state. The tail end of the main beam is movably hinged to the tail of the chassis frame through a four-connecting-rod mechanism, the bucket is assembled to the front end of the main beam, an unloadingoil cylinder for driving loading and unloading is assembled between the bucket and the main beam, and a lifting oil cylinder for driving the main beam to swing up and down to achieve lifting of the bucket is assembled between the main beam and the chassis frame. Compared with existing loading equipment, the sliding loading machine has the advantages that detachment and maintenance are convenient,work is reliable, and the structure is compact.

Owner:SUNWARD INTELLIGENT EQUIP CO LTD

Method for preparing catalyst in preparation of acrylic acid by oxidizing acrolein

ActiveCN102114427BAvoid the danger of vandalismEasy to useOrganic compound preparationCarboxylic compound preparationPtru catalystAcrolein

Owner:SHANGHAI HUAYI NEW MATERIAL

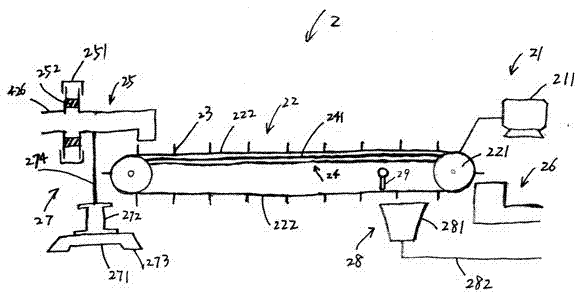

Drying treatment system of slurry

ActiveCN103134288AImprove stabilityLow costDrying machines with non-progressive movementsPreliminary solid treatment for dryingCouplingSlurry

The invention relates to a drying treatment system of slurry. The drying treatment system is characterized by comprising a slurry raw material storing warehouse, a scraper conveying machine, a prepared material cabin, a slurry drying machine, a coal dust gas dusting machine, a gas recycling device and a finished product storing warehouse. If a chain wheel of the scraper conveying machine in the treatment system needs to be replaced, users only need to detach a plurality of bolts instead of detaching a coupler, a bearing base, an end cover and a bearing, so that the chain wheel can be replaced, the replacing procedures are greatly reduced, and the replacing efficiency is greatly improved. The drying treatment system has the advantages of being low in energy consumption, low in noise, strong in structural stability, high in processing efficiency, low in device cost, strong in device adaptation, free of blocking, less in production failure, low in manufacture cost, and capable of saving resources.

Owner:YUNNAN ZHONGYI DINGDONG ENERGY TECH DEV

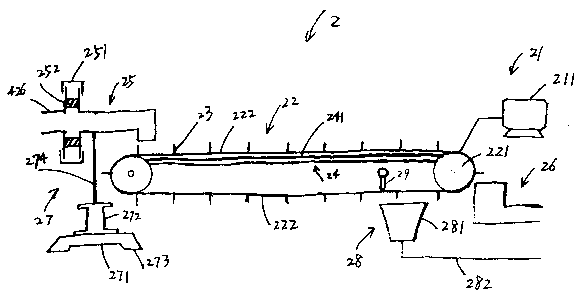

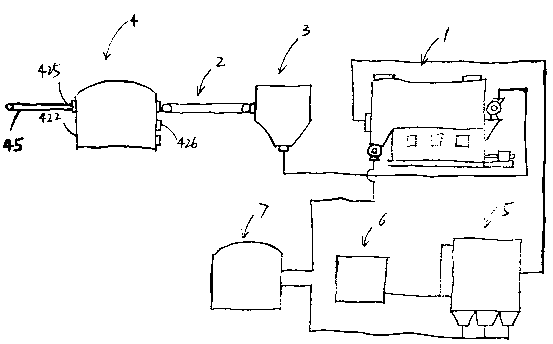

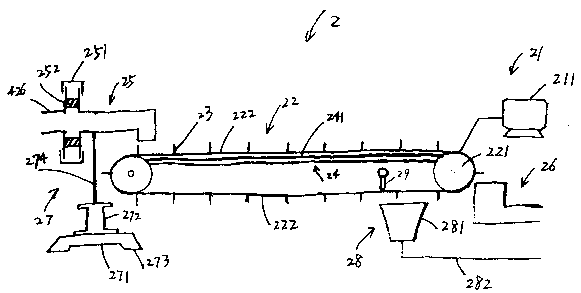

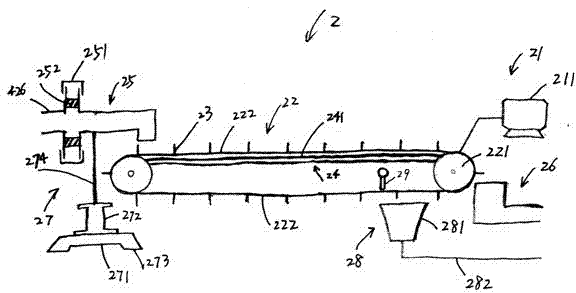

Drying process production line of coal slime

ActiveCN103123211AImprove stabilityLow costDrying machines with non-progressive movementsPreliminary solid treatment for dryingResource savingCoal dust

The invention relates to a drying process production line of coal slime. The drying process production line of the coal slime is characterized by comprising a coal slime raw material storage warehouse, a scraper conveyer, a preparing storage bin, a coal slime drying machine, a coal dust gas dusting machine, a gas recycling device and a finished product storage warehouse. A stirring device of the coal slime drying machine in the production line is provided with a large torque starter. A motor can recover to a normal working state rapidly by the starter so that drying production efficiency of the coal slime materials can be improved, and meanwhile labor cost is saved. The drying process production line of the coal slime has the advantages of being low in energy consumption, low in noise, good in structure stability, high in processing efficiency, low in equipment cost, good in equipment adaptability, free from material blocking phenomenon, small in production malfunction, low in manufacturing cost and resource-saving.

Owner:YUNNAN ZHONGYI DINGDONG ENERGY TECH DEV

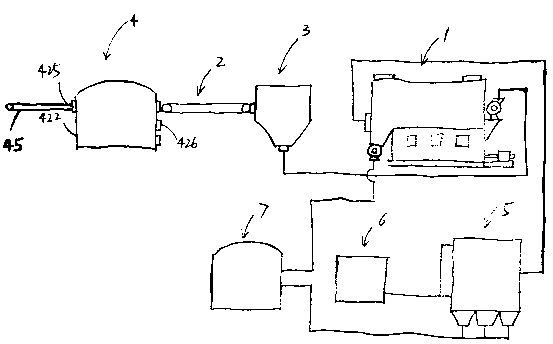

Drying treatment production line of slurry

ActiveCN103134282AImprove stabilityLow costDrying machines with non-progressive movementsPreliminary solid treatment for dryingProduction lineSlurry

The invention relates to a drying treatment production line of slurry. The drying treatment production line is characterized by comprising a slurry raw material storing warehouse, a scraper conveying machine, a prepared material cabin, a slurry drying machine, a coal dust gas dusting machine, a gas recycling device and a finished product storing warehouse. A heat source control device is arranged on a hot air inlet portion of the slurry drying machine of the production line, hot air inlet amount can be regulated according to the moisture content of the fed materials of the drying device to achieve the aim of energy saving, and simultaneously, the drying treatment production line is convenient to adjust, easy to operate and capable of saving a large amount of manpower and time. The drying treatment production line has the advantages of being low in energy consumption, low in noise, strong in structural stability, high in processing efficiency, low in device cost, strong in device adaptation, free of blocking, less in production failure, low in manufacture cost, and capable of saving resources.

Owner:YUNNAN ZHONGYI DINGDONG ENERGY TECH DEV

Drying treatment system of slurry

ActiveCN103134287AImprove stabilityLow costDrying machines with non-progressive movementsPreliminary solid treatment for dryingThermal insulationSlurry

The invention relates to a drying treatment system of slurry. The drying treatment system is characterized by comprising a slurry raw material storing warehouse, a scraper conveying machine, a prepared material cabin, a slurry drying machine, a coal dust gas dusting machine, a gas recycling device and a finished product storing warehouse. Material raising teeth of the slurry drying machine in the treatment system can effectively eliminate the phenomenon of journal sticking of sticky materials, and the drying treatment system of slurry is abrasion-resisting and thermal-insulation and can effectively improve production efficiency and prolong the service life. The drying treatment system has the advantages of being low in energy consumption, low in noise, strong in structural stability, high in processing efficiency, low in device cost, strong in device adaptation, free of blocking, less in production failure, low in manufacture cost, and capable of saving resources.

Owner:YUNNAN ZHONGYI DINGDONG ENERGY TECH DEV

A data interaction method and client and server

ActiveCN102624740BPrevent tamperingAvoid the danger of vandalismUser identity/authority verificationTimestampClient-side

The invention provides a data interaction method, a client and a server, so as to solve the problems of requested replaying and client computer safety that cannot be solved by adopting HTTPS (Hyper Text Transfer Protocol Secure) technique. The method comprises the following steps: obtaining a timestamp from a service terminal; sending the first identifying information of a user, the timestamp and verifying data generated according to the first identifying information of the user and the timestamp to the service terminal; obtaining certified data encrypted by the service terminal, wherein the certified data comprises the encrypted data generated for the timestamp and second identifying information of the user; and using the certified data to access the service terminal. According to the method provided by the invention, HTTPS encryption and improved MD5 are used together while the encryptions at the client and service terminal are adopted, so that the possibility of distorting and falsifying data at 'end' and 'path' is efficiently avoided. Besides, the timeliness control is performed on interface calling by using effective time through the timestamp, so that the data damage risk caused by recording and largely replaying a user request is efficiently avoided.

Owner:BEIJING QIHOO TECH CO LTD

Drying process production line of coal slime

ActiveCN103123211BImprove stabilityLow costDrying machines with non-progressive movementsPreliminary solid treatment for dryingProduction lineResource saving

Owner:YUNNAN ZHONGYI DINGDONG ENERGY TECH DEV

Production line used for drying coal slime

ActiveCN103134289BImprove stabilityLow costDrying machines with non-progressive movementsPreliminary solid treatment for dryingLow noiseProduction line

The invention relates to a production line used for drying coal slime. The production line used for drying the coal slime is characterized by comprising a coal slime raw material repository, a scraper conveyor, a preparatory material storage bin, a coal slime drier, a coal dust gas dusting machine, a gas recycling device and a finished product repository, wherein reinforcing ribs arranged in a drying cabin of the coal slime drier of the production line can guarantee no deformation of the cabin body of the drying cabin in a high pressure environment; and thermal insulation cotton among the reinforcing ribs guarantees heat loss of the drying cabin to be as low as possible, realizes the energy-saving purpose and lowers the production cost. The production line used for drying the coal slime has the advantages of low energy consumption, low noise, strong structure stability, high processing efficiency, low equipment cost, strong equipment adaptability, no material blockage phenomenon, few production faults, low manufacturing cost and resource economization.

Owner:YUNNAN ZHONGYI DINGDONG ENERGY TECH DEV

Production line used for drying coal slime

ActiveCN103134291BImprove stabilityLow costDrying machines with non-progressive movementsPreliminary solid treatment for dryingLow noiseAtmospheric air

The invention relates to a production line used for drying coal slime. The production line used for drying the coal slime is characterized by comprising a coal slime raw material repository, a scraper conveyor, a preparatory material storage bin, a coal slime drier, a coal dust gas dusting machine, a gas recycling device and a finished product repository, wherein a desulfuration and purification device for absorbing sulfur dioxide generated in the coal slime drying process is arranged at an exhaust port of the coal dust gas dusting machine of the production line, so that the quality of gas exhausted to the atmosphere is guaranteed and air pollution is avoided; and an overhaul hole enables the replacement of the desulfuration and purification device to be more convenient, so that the trouble of detaching a pipeline is avoided. The production line used for drying the coal slime has the advantages of low energy consumption, low noise, strong structure stability, high processing efficiency, low equipment cost, strong equipment adaptability, no material blockage phenomenon, few production faults, low manufacturing cost and resource economization.

Owner:YUNNAN ZHONGYI DINGDONG ENERGY TECH DEV

Drying treatment system of slurry

ActiveCN103134286BImprove stabilityLow costDrying machines with non-progressive movementsPreliminary solid treatment for dryingWorking environmentPulp and paper industry

The invention relates to a drying treatment system of slurry. The drying treatment system is characterized by comprising a slurry raw material storing warehouse, a scraper conveying machine, a prepared material cabin, a slurry drying machine, a coal dust gas dusting machine, a gas recycling device and a finished product storing warehouse. A rapping device is arranged on a casing of a drying cabin of the slurry drying machine in the treatment system, so that materials hung on the inner wall of the drying machine are thoroughly eliminated, vibration on the casing of the drying machine is effectively relieved, and working environment protection, service life prolonging of the drying machine and production efficiency improvement are facilitated. The drying treatment system has the advantages of being low in energy consumption, low in noise, strong in structural stability, high in processing efficiency, low in device cost, strong in device adaptation, free of blocking, less in production failure, low in manufacture cost, and capable of saving resources.

Owner:YUNNAN ZHONGYI DINGDONG ENERGY TECH DEV

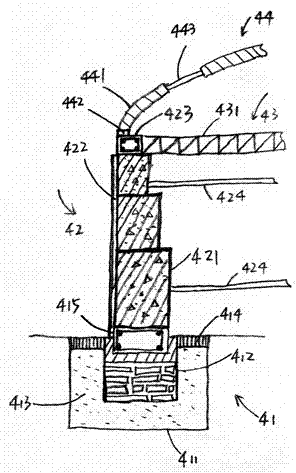

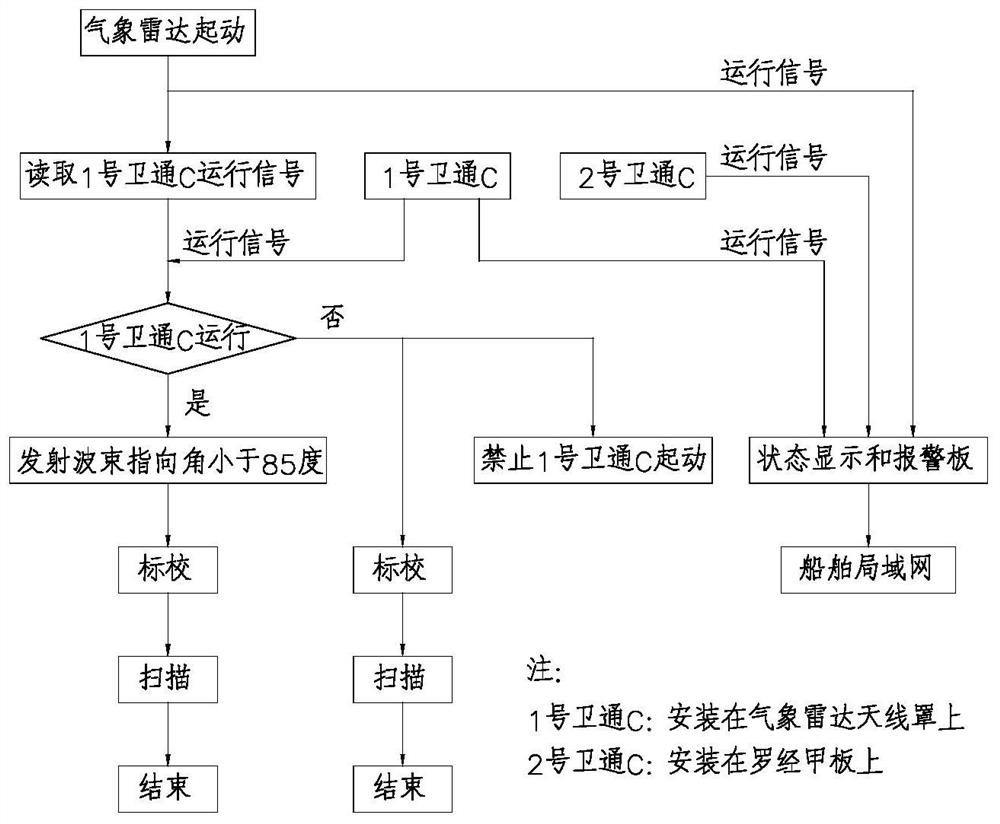

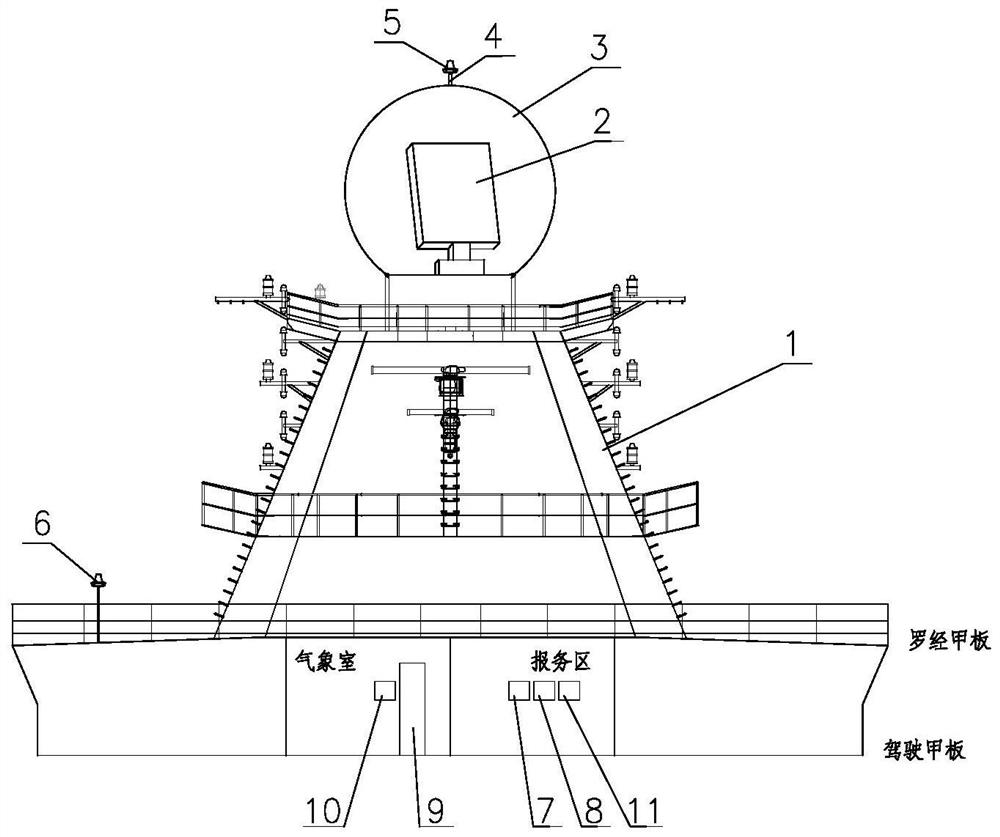

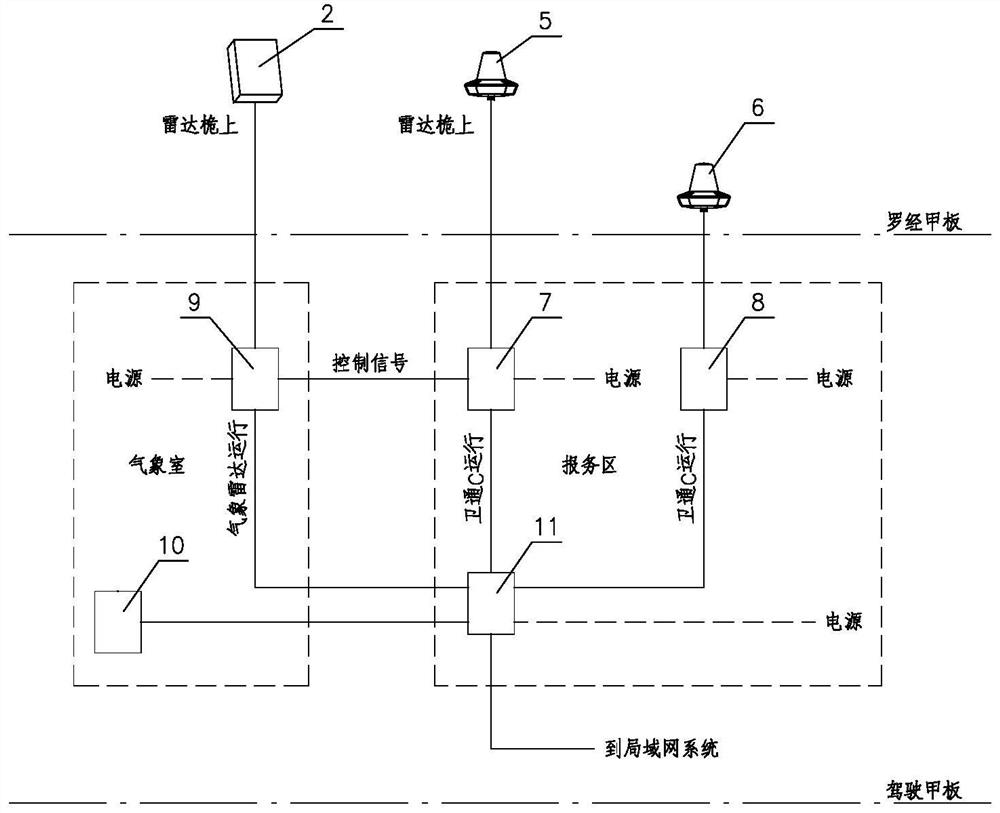

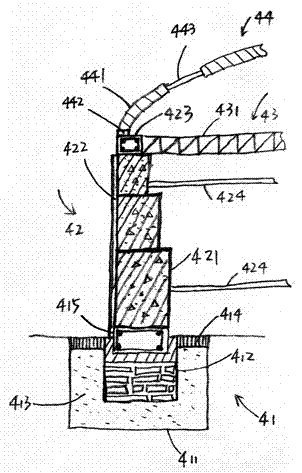

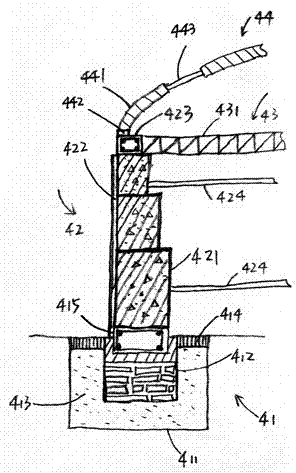

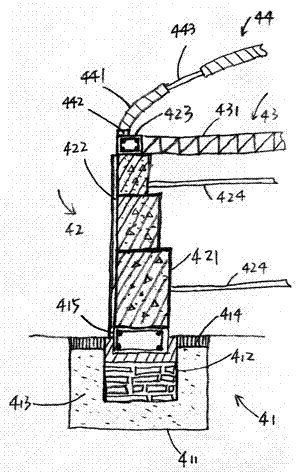

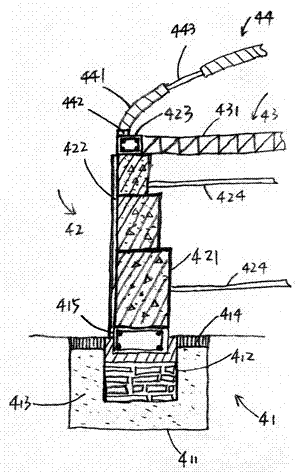

An interlocking control device for scientific research ship weather radar and satellite c-antenna

ActiveCN111834729BAvoid the danger of vandalismAntenna supports/mountingsAntenna adaptation in movable bodiesWeather radarEngineering

The invention discloses a weather radar and satellite communication C antenna interlocking control device for scientific research ship, which includes a radar mast, a weather radar antenna and controller, two satellite C antennas and controllers, several satellite communication C and weather radars Operation status display and alarm board, several power supplies, communication and control cables, weather radar air-to-air calibration and detection requires the antenna to be unobstructed and has a high transmission power, and Satcom C’s air-to-air sending and receiving navigation information also requires the antenna to be unobstructed and easily damaged Signal interference, the two have conflicts in spatial arrangement and signal electromagnetic compatibility. The present invention installs the weather radar antenna at the highest possible point of the radar mast, and wherein a set of satellite communication C antenna is installed on the top of the weather radar antenna. The satellite communication C and The signal transmission between the weather radar controllers realizes the control chain of the two systems, which not only avoids the danger of Satcom C antenna being damaged by the weather radar antenna, but also ensures the effectiveness and accuracy of the weather radar in air calibration and detection.

Owner:708TH RES INST OF CSSC

Production line used for drying coal slime

ActiveCN103134292AImprove stabilityLow costDrying machines with non-progressive movementsPreliminary solid treatment for dryingProduction lineLow noise

The invention relates to a production line used for drying coal slime. The production line used for drying the coal slime is characterized by comprising a coal slime raw material repository, a scraper conveyor, a preparatory material storage bin, a coal slime drier, a coal dust gas dusting machine, a gas recycling device and a finished product repository, wherein a main pipe body of a hot air conveying pipe of the coal slime drier of the production line is made of a steel plate, so that pressure bearing intensity of the pipe body is guaranteed; a front explosion-proof port and a rear explosion-proof port are arranged at the front and rear ends of the main pipe body, so that equipment damage caused by over-pressure in the pipeline is avoided; and the inner wall of the main pipe body is provided with a spiral groove which extends along an air blowing direction, so that the flow speed of the hot air is speeded up, and drying efficiency is increased. The production line used for drying the coal slime has the advantages of low energy consumption, low noise, strong structure stability, high processing efficiency, low equipment cost, strong equipment adaptability, no material blockage phenomenon, few production faults, low manufacturing cost and resource economization.

Owner:YUNNAN ZHONGYI DINGDONG ENERGY TECH DEV

Drying treatment system of slurry

ActiveCN103134285BImprove stabilityLow costDrying machines with non-progressive movementsPreliminary solid treatment for dryingThermal insulationSlurry

The invention relates to a drying treatment system of slurry. The drying treatment system is characterized by comprising a slurry raw material storing warehouse, a scraper conveying machine, a prepared material cabin, a slurry drying machine, a coal dust gas dusting machine, a gas recycling device and a finished product storing warehouse. The inner wall of an overhaul door of the slurry drying machine in the treatment system is made of materials which are not apt to deform under high temperature and smooth in surface, so that the phenomenon of wall sticking of sticky materials is avoided. The inner wall and the outer wall of the overhaul door are separated from each other through thermal insulation materials, so that deformation of the outer wall and the inner wall is reduced to the minimum degree, and tightness of the overhaul door can be guaranteed. A set of electric actuator is introduced, and automation in opening and closing of the overhaul door can be achieved. The drying treatment system has the advantages of being low in energy consumption, low in noise, strong in structural stability, high in processing efficiency, low in device cost, strong in device adaptation, free of blocking, less in production failure, low in manufacture cost, and capable of saving resources.

Owner:YUNNAN ZHONGYI DINGDONG ENERGY TECH DEV

Drying treatment production line of slurry

ActiveCN103134282BImprove stabilityLow costDrying machines with non-progressive movementsPreliminary solid treatment for dryingProduction lineSlurry

The invention relates to a drying treatment production line of slurry. The drying treatment production line is characterized by comprising a slurry raw material storing warehouse, a scraper conveying machine, a prepared material cabin, a slurry drying machine, a coal dust gas dusting machine, a gas recycling device and a finished product storing warehouse. A heat source control device is arranged on a hot air inlet portion of the slurry drying machine of the production line, hot air inlet amount can be regulated according to the moisture content of the fed materials of the drying device to achieve the aim of energy saving, and simultaneously, the drying treatment production line is convenient to adjust, easy to operate and capable of saving a large amount of manpower and time. The drying treatment production line has the advantages of being low in energy consumption, low in noise, strong in structural stability, high in processing efficiency, low in device cost, strong in device adaptation, free of blocking, less in production failure, low in manufacture cost, and capable of saving resources.

Owner:YUNNAN ZHONGYI DINGDONG ENERGY TECH DEV

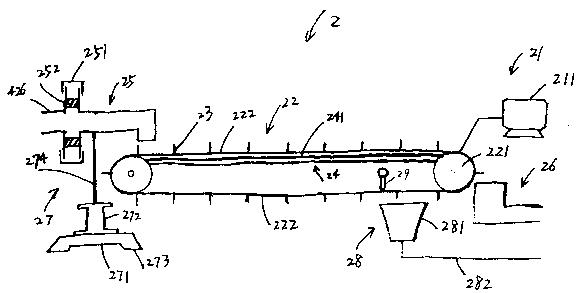

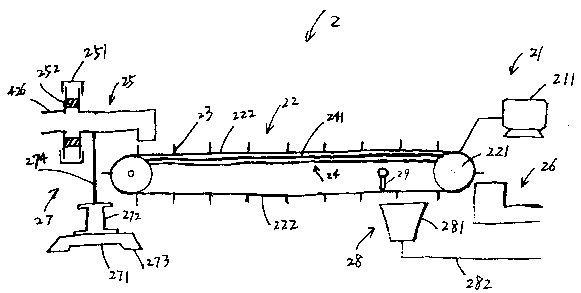

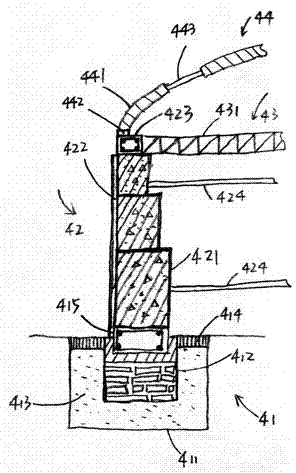

Drying processing system of coal slime

ActiveCN103115482AImprove stabilityLow costDrying machines with non-progressive movementsPreliminary solid treatment for dryingHandling systemAdhesive materials

The invention relates to a drying processing system of coal slime. The drying processing system is characterized by comprising a coal slime raw material storage bin, a scraper conveyor, a prepared material bin, a coal slime drying machine, a coal dust gas dusting machine, a gas recycling device and an end product storage bin. The scraper conveyor in the processing system is provided with a vibration material guide bin on a material inlet, the vibration material guide bin utilizing a vibration increasing spring enables vibration of a vibrator to be enhanced, restriction of a support does not exist, strong vibration can be produced, adhesive material can be smoothly led to a conveying belt of the scraper conveyor, and drying production efficiency of coal slime material is greatly improved. The drying processing system has the advantages of being low in energy consumption, small in noise, strong in structure stability, high in processing efficiency, low in equipment cost, strong in equipment adaptability, free of a blocking phenomenon, few in production fault, and low in manufacturing cost, and saving sources.

Owner:YUNNAN ZHONGYI DINGDONG ENERGY TECH DEV

Production line used for drying coal slime

ActiveCN103134294AImprove stabilityLow costDrying machines with non-progressive movementsPreliminary solid treatment for dryingLow noiseProduction line

The invention relates to a production line used for drying coal slime. The production line used for drying the coal slime is characterized by comprising a coal slime raw material repository, a scraper conveyor, a preparatory material storage bin, a coal slime drier, a coal dust gas dusting machine, a gas recycling device and a finished product repository, wherein the gas recycling device of the production line is additionally provided with a secondary dust removal device, namely, a cyclone dust collector; and a small number of fine coal dust still existing in an intake airflow is separated from the airflow under the action of an inert centrifugal force through the rotation of a worm wheel, is thrown to the inner wall of the shell of the cyclone dust collector, and finally falls into a recycling hopper of the cyclone dust collector. The secondary dust removal further guarantees the quality of the gas exhausted to the atmosphere and belongs to an extremely environment-friendly gas recycling device. The production line used for drying the coal slime has the advantages of low energy consumption, low noise, strong structure stability, high processing efficiency, low equipment cost, strong equipment adaptability, no material blockage phenomenon, few production faults, low manufacturing cost and resource economization.

Owner:YUNNAN ZHONGYI DINGDONG ENERGY TECH DEV

Drying treatment system of slurry

ActiveCN103134286AImprove stabilityLow costDrying machines with non-progressive movementsPreliminary solid treatment for dryingCoal dustDust control

The invention relates to a drying treatment system of slurry. The drying treatment system is characterized by comprising a slurry raw material storing warehouse, a scraper conveying machine, a prepared material cabin, a slurry drying machine, a coal dust gas dusting machine, a gas recycling device and a finished product storing warehouse. A rapping device is arranged on a casing of a drying cabin of the slurry drying machine in the treatment system, so that materials hung on the inner wall of the drying machine are thoroughly eliminated, vibration on the casing of the drying machine is effectively relieved, and working environment protection, service life prolonging of the drying machine and production efficiency improvement are facilitated. The drying treatment system has the advantages of being low in energy consumption, low in noise, strong in structural stability, high in processing efficiency, low in device cost, strong in device adaptation, free of blocking, less in production failure, low in manufacture cost, and capable of saving resources.

Owner:YUNNAN ZHONGYI DINGDONG ENERGY TECH DEV

Coal slime drying treatment production line

ActiveCN103134283BImprove stabilityLow costDrying machines with non-progressive movementsPreliminary solid treatment for dryingProduction lineResource saving

The invention relates to a coal slime drying treatment production line. The coal slime drying treatment production line is characterized by comprising a coal slime raw material storing repository, a scraping plate conveyer, a prepared material bin, a coal slime drying machine, a coal dust gas dust removing machine, a gas recycling device and a finished product storing repository. The coal dust gas dust removing machine in the production line is provided with a heating device at the position of an air inlet, the heating device heats the tail gas temperature from 60-120 DEG C to 160-190 DEG C and then enters into the dust removing machine to enable coal dust to be further dried, and a phenomenon that cloth bags are blocked by coal dust is avoided. The coal slime drying treatment production line has the advantages of being low in energy consumption, small in noise, strong in structural stability, high in processing efficiency, low in device cost, strong in adaptability, free of blocking phenomena, few in production faults, low in manufacture cost and resource-saving.

Owner:YUNNAN ZHONGYI DINGDONG ENERGY TECH DEV

Drying treatment system of slurry

ActiveCN103134288BImprove stabilityLow costDrying machines with non-progressive movementsPreliminary solid treatment for dryingCouplingSlurry

The invention relates to a drying treatment system of slurry. The drying treatment system is characterized by comprising a slurry raw material storing warehouse, a scraper conveying machine, a prepared material cabin, a slurry drying machine, a coal dust gas dusting machine, a gas recycling device and a finished product storing warehouse. If a chain wheel of the scraper conveying machine in the treatment system needs to be replaced, users only need to detach a plurality of bolts instead of detaching a coupler, a bearing base, an end cover and a bearing, so that the chain wheel can be replaced, the replacing procedures are greatly reduced, and the replacing efficiency is greatly improved. The drying treatment system has the advantages of being low in energy consumption, low in noise, strong in structural stability, high in processing efficiency, low in device cost, strong in device adaptation, free of blocking, less in production failure, low in manufacture cost, and capable of saving resources.

Owner:YUNNAN ZHONGYI DINGDONG ENERGY TECH DEV

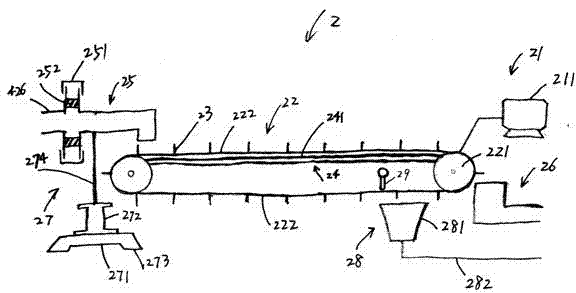

Coal slurry-drying production line

ActiveCN103148683BImprove stabilityLow costDrying machines with non-progressive movementsPreliminary solid treatment for dryingProduction lineResource saving

The invention relates to a coal slurry-drying production line. The coal slurry-drying production line is characterized in that the coal slurry-drying production line comprises a coal slurry storage silo, a scraper conveyer, a preparatory bin, a coal slurry dryer, a coal dust gas deduster, a gas-recycling unit and a finished product storage silo. Because a retractable discharge hopper unit in the production line adopts a retractable hopper design, flying dust in discharge can be effectively reduced; as retractable shells are extended or retracted, a retractable sleeve is extended or retracted, and thereby flying dust can be further prevented from leaking out; and a guiding track can control the moving track of the retractable shells to prevent the deflection of the retractable shells, thus further guaranteeing the accuracy of the discharge position. The coal slurry-drying production line has the advantages of low energy consumption, little noise, high structural stability, high processing efficiency, low equipment cost, high equipment adaptability, no blockage, less production failure, low production cost and resource saving.

Owner:YUNNAN ZHONGYI DINGDONG ENERGY TECH DEV

Drying treatment system of slurry

ActiveCN103134284BImprove stabilityLow costDrying machines with non-progressive movementsPreliminary solid treatment for dryingLoad torquePulp and paper industry

The invention relates to a drying treatment system of slurry. The drying treatment system is characterized by comprising a slurry raw material storing warehouse, a scraper conveying machine, a prepared material cabin, a slurry drying machine, a coal dust gas dusting machine, a gas recycling device and a finished product storing warehouse. A material raising shaft of the slurry drying machine in the treatment system is made of high-temperature-resisting materials and adopts a loading torque loop, so that the material raising shaft cannot deform under high-temperature, high-speed and large-torque operation, the material raising capability and the torque bearing capability of the material raising shaft are greatly improved, and the material raising efficiency and the working stability are greatly improved. The drying treatment system has the advantages of being low in energy consumption, low in noise, strong in structural stability, high in processing efficiency, low in device cost, strong in device adaptation, free of blocking, less in production failure, low in manufacture cost, and capable of saving resources.

Owner:YUNNAN ZHONGYI DINGDONG ENERGY TECH DEV

Production line used for drying coal slime

ActiveCN103134294BImprove stabilityLow costDrying machines with non-progressive movementsPreliminary solid treatment for dryingLow noiseAtmospheric air

The invention relates to a production line used for drying coal slime. The production line used for drying the coal slime is characterized by comprising a coal slime raw material repository, a scraper conveyor, a preparatory material storage bin, a coal slime drier, a coal dust gas dusting machine, a gas recycling device and a finished product repository, wherein the gas recycling device of the production line is additionally provided with a secondary dust removal device, namely, a cyclone dust collector; and a small number of fine coal dust still existing in an intake airflow is separated from the airflow under the action of an inert centrifugal force through the rotation of a worm wheel, is thrown to the inner wall of the shell of the cyclone dust collector, and finally falls into a recycling hopper of the cyclone dust collector. The secondary dust removal further guarantees the quality of the gas exhausted to the atmosphere and belongs to an extremely environment-friendly gas recycling device. The production line used for drying the coal slime has the advantages of low energy consumption, low noise, strong structure stability, high processing efficiency, low equipment cost, strong equipment adaptability, no material blockage phenomenon, few production faults, low manufacturing cost and resource economization.

Owner:YUNNAN ZHONGYI DINGDONG ENERGY TECH DEV

Production line used for drying coal slime

ActiveCN103134290BImprove stabilityLow costDrying machines with non-progressive movementsPreliminary solid treatment for dryingLow noiseProduction line

The invention relates to a production line used for drying coal slime. The production line used for drying the coal slime is characterized by comprising a coal slime raw material repository, a scraper conveyor, a preparatory material storage bin, a coal slime drier, a coal dust gas dusting machine, a gas recycling device and a finished product repository, wherein an air speed adjusting valve which is convenient to control a flow speed of hot air in the coal slime drier is arranged at an air outlet of a blower of the coal slime drier of the production line, and a temperature control device which is convenient to control the temperature of the hot air flowing into the coal slime drier is arranged in a hot air inlet pipe, so that heat energy waste is avoided; and thermal insulation cotton is sleeved outside the hot air inlet pipe, so that heat loss is further reduced, and production cost is saved. The production line used for drying the coal slime has the advantages of low energy consumption, low noise, strong structure stability, high processing efficiency, low equipment cost, strong equipment adaptability, no material blockage phenomenon, few production faults, low manufacturing cost and resource economization.

Owner:YUNNAN ZHONGYI DINGDONG ENERGY TECH DEV

Production line used for drying coal slime

ActiveCN103134292BImprove stabilityLow costDrying machines with non-progressive movementsPreliminary solid treatment for dryingProduction lineLow noise

Owner:YUNNAN ZHONGYI DINGDONG ENERGY TECH DEV

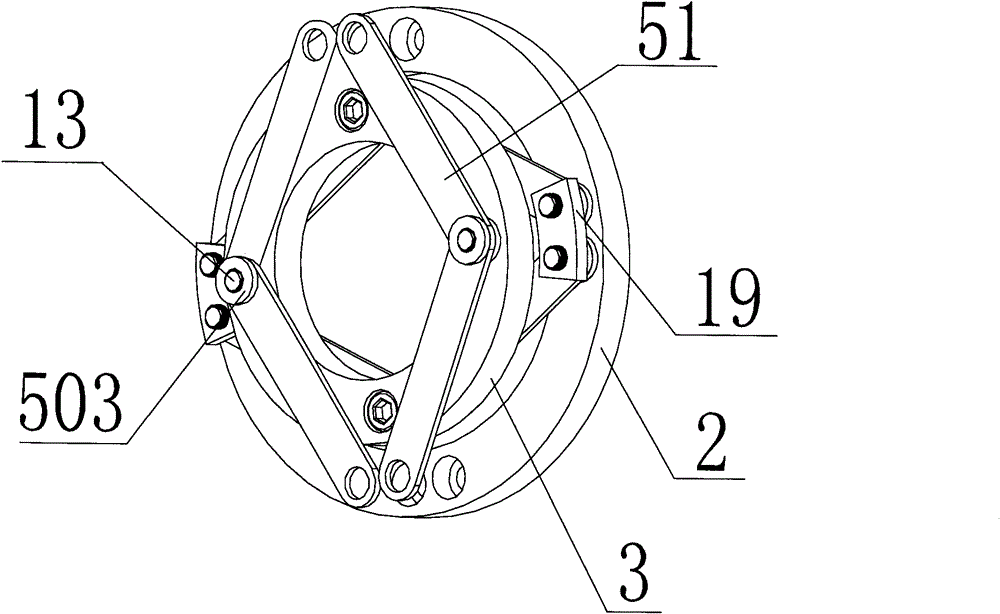

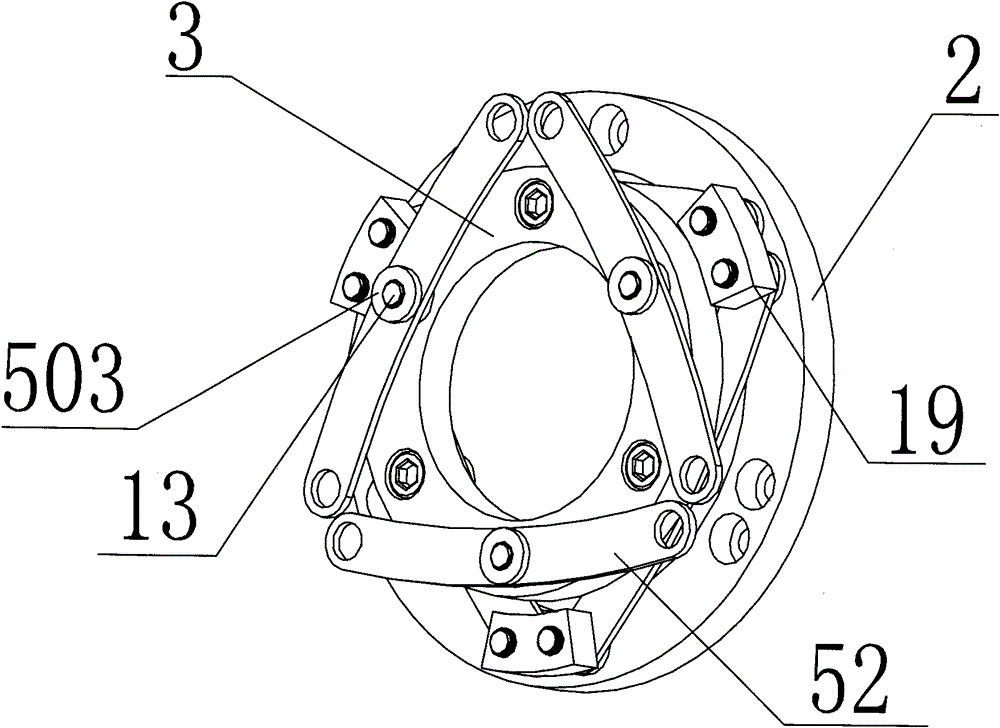

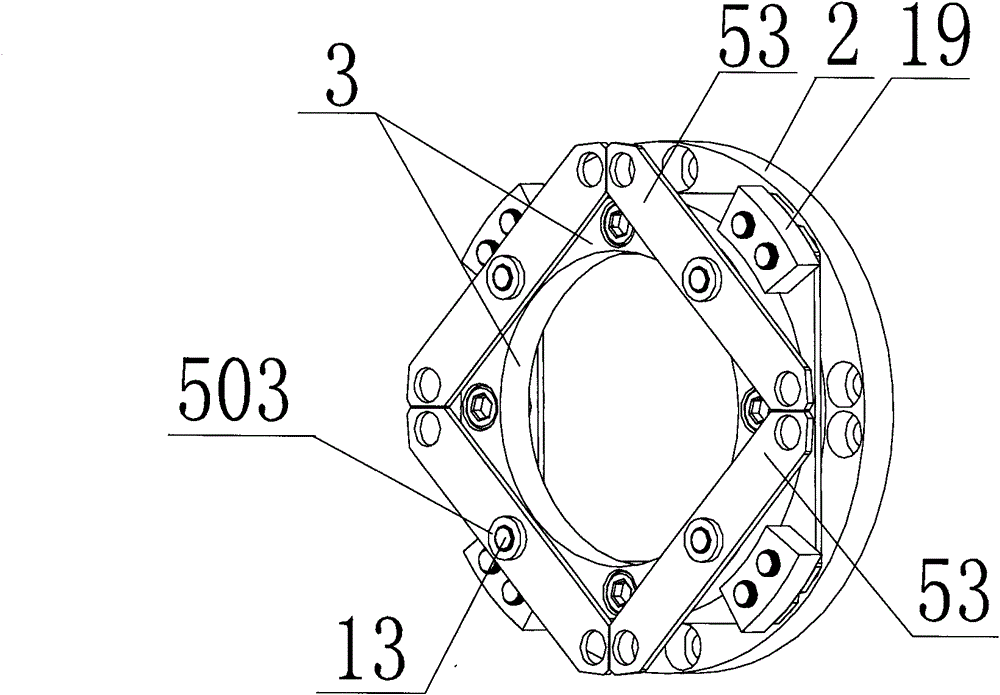

Cordwood special-shaped diaphragm flexible shaft coupling

InactiveCN101886672BImprove displacement compensation (deviation correction) abilityGood transmission effectYielding couplingWind drivenLow noise

The invention discloses a cordwood special-shaped diaphragm flexible shaft coupling comprising a flange and special-shaped diaphragm combination units. Each special-shaped diaphragm combination unit comprises two special-shaped diaphragm chains and a spacing disc or a linkage ring between the special-shaped diaphragm chains, every two special-shaped diaphragm combination units are connected with the spacing disc or a spacing shaft or the linkage ring or a linkage shaft, and the special-shaped diaphragm chains are divided into single-layer special-shaped diaphragm chains and compound special-shaped diaphragm chains; each single-layer special-shaped diaphragm chain is formed by tightly connecting at least two three-hole special-shaped diaphragm laminating members from head to tail, each compound special-shaped diaphragm chain is formed by complementing, staggering and laminating two staircase type special-shaped diaphragm chains on space, and each staircase type special-shaped diaphragmchain is formed by staggering a plurality of two-hole special-shaped diaphragm laminating members from top to bottom and laminating the two-hole special-shaped diaphragm laminating members from head to tail. The invention has the advantages of correction angle (triangle phi is equal to 3 degrees), no lubrication or maintenance, durability, ultra compactness, airflow shielding, low noise and cost,electric insulation, overload protection and on-site free assembly and disassembly and is suitable for wind-driven generators required to constantly work in 80-m high altitude and a harsh environmentwith large temperature difference all the year round.

Owner:黄天梵

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com