Production line used for drying coal slime

A production line and coal slime technology, which is applied in the field of coal slime drying production line, can solve the problems of low processing efficiency, non-conformity with a conservation-oriented society, waste of resources, etc., improve the ability to resist rain and snow loads, prevent abnormal discharge, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

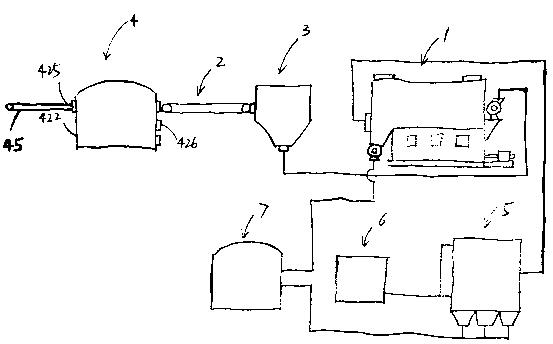

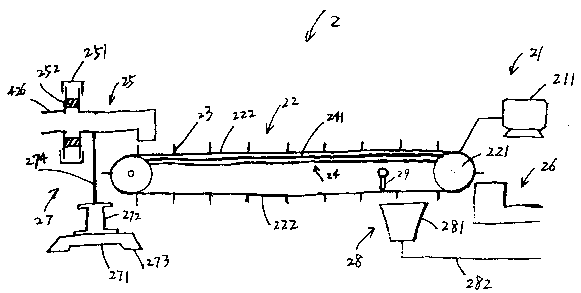

[0033] A production line for drying coal slime, which is characterized in that it includes a coal slime raw material storage warehouse 4, a scraper conveyor 2, a preliminary silo 3, a coal slime dryer 1, a coal dust gas dust collector 5, and a gas recycling device 6. Finished product storage warehouse 7, including:

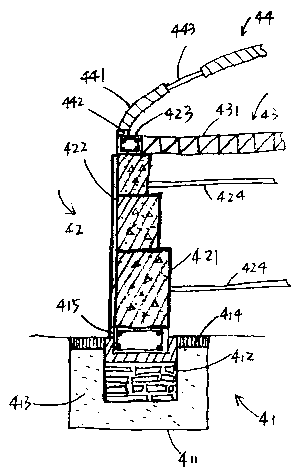

[0034] The coal slime raw material storage warehouse 4 includes: a foundation 41, a side enclosure 42, a top bracket 43, and a top cover 44. The foundation includes a 1 meter wide and 5 meter deep trench 411 in which shale strips are set. Masonry foundation 412, cement mortar is filled between the shale, the mass ratio of the cement mortar is cement: sand: water = 3.2: 2.1:1, and the space between the strip masonry foundation and the trench 413 Filled with fly ash and tamped, pave the top of the fly ash with a quality ratio of cement: sand: water = 3: 1: 1 cement mortar leveling layer 414, and embed the bottom ring beam 415 in the leveling layer. The mass ratio betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com