Wheel support device

一种支承装置、车轮的技术,应用在车轮、动力装置、控制装置等方向,能够解决车辆乘坐舒适性恶化等问题,达到抑制车辆乘坐舒适性的恶化、防止接触、降低强度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

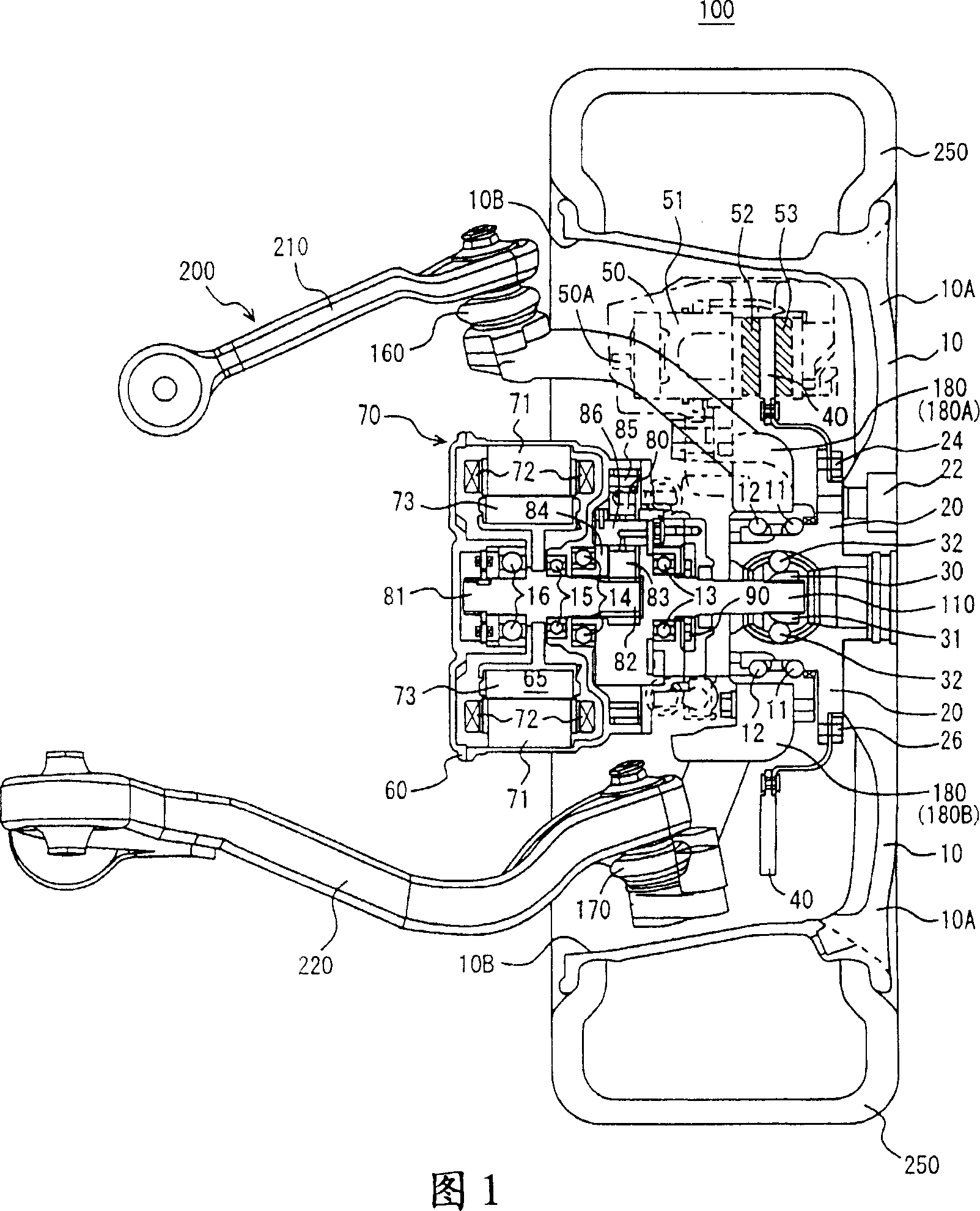

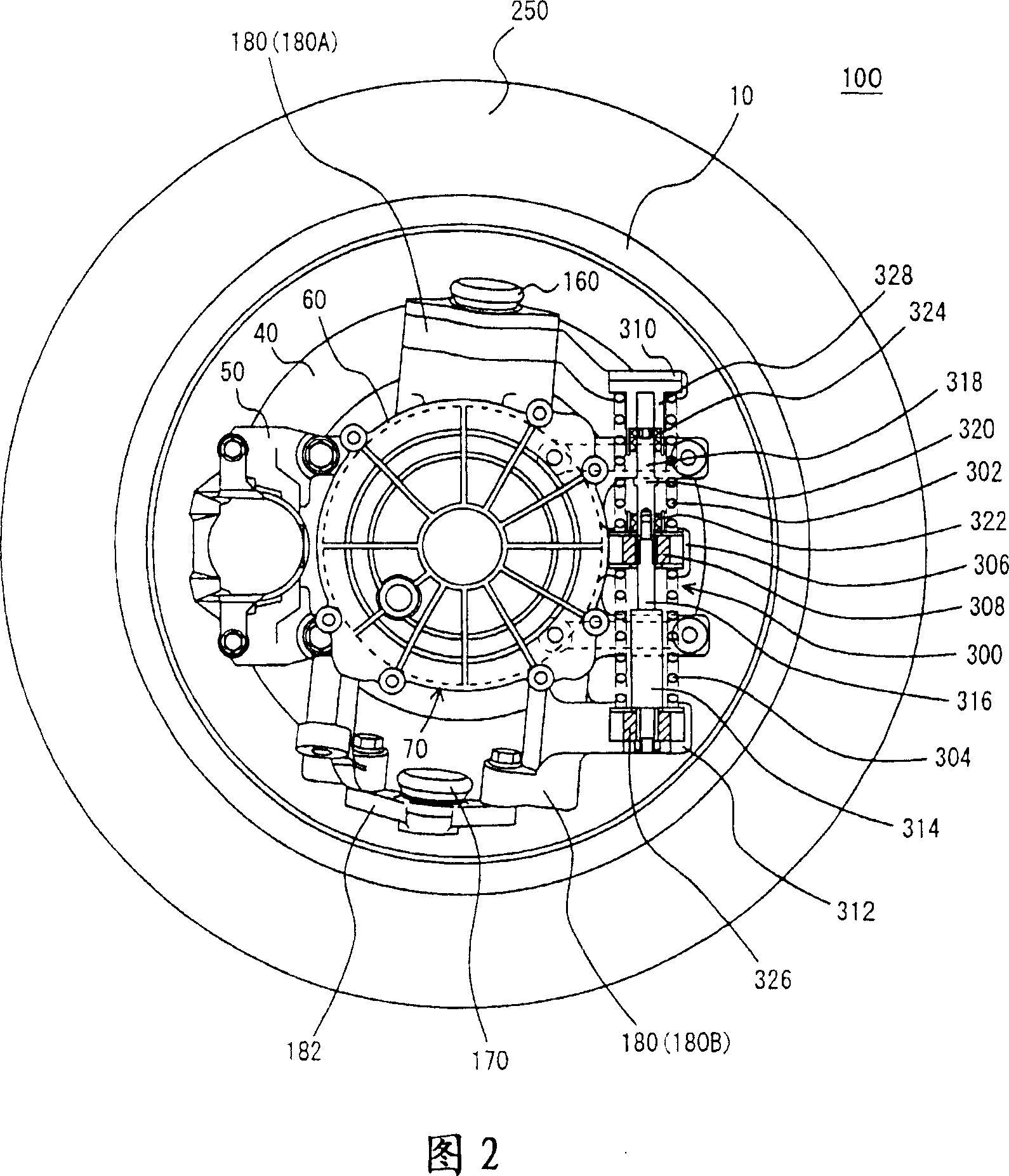

[0031] As shown in Figure 1, according to the first embodiment of the present invention, the electric wheel 100 supported by the wheel support device 200 is composed of a spoke 10, a hub 20, a constant velocity joint 30, a brake disc 40, a brake caliper 50, and an in-wheel motor. 70 and tire 250 are formed.

[0032] The in-wheel motor 70 is formed of a housing 60, a motor 65, a planetary gear 80, an oil pump 90, a shaft 110, and an oil passage (not shown).

[0033] The wheel support device 200 is formed of a dynamic mass damper mechanism (not shown), ball joints 160, 170, knuckle 180, upper arm 210, lower arm 220, and shock absorbers (impact absorbers, not shown).

[0034] The spoke 10 is substantially cup-shaped, and is formed of a disc portion 10A and a rim portion 10B. The spokes 10 may be configured to accommodate the hub 20 , the brake disc 40 , the brake caliper 50 and the in-wheel motor 70 . The spokes 10 are connected to the hub 20 by fastening the disc portion 10A t...

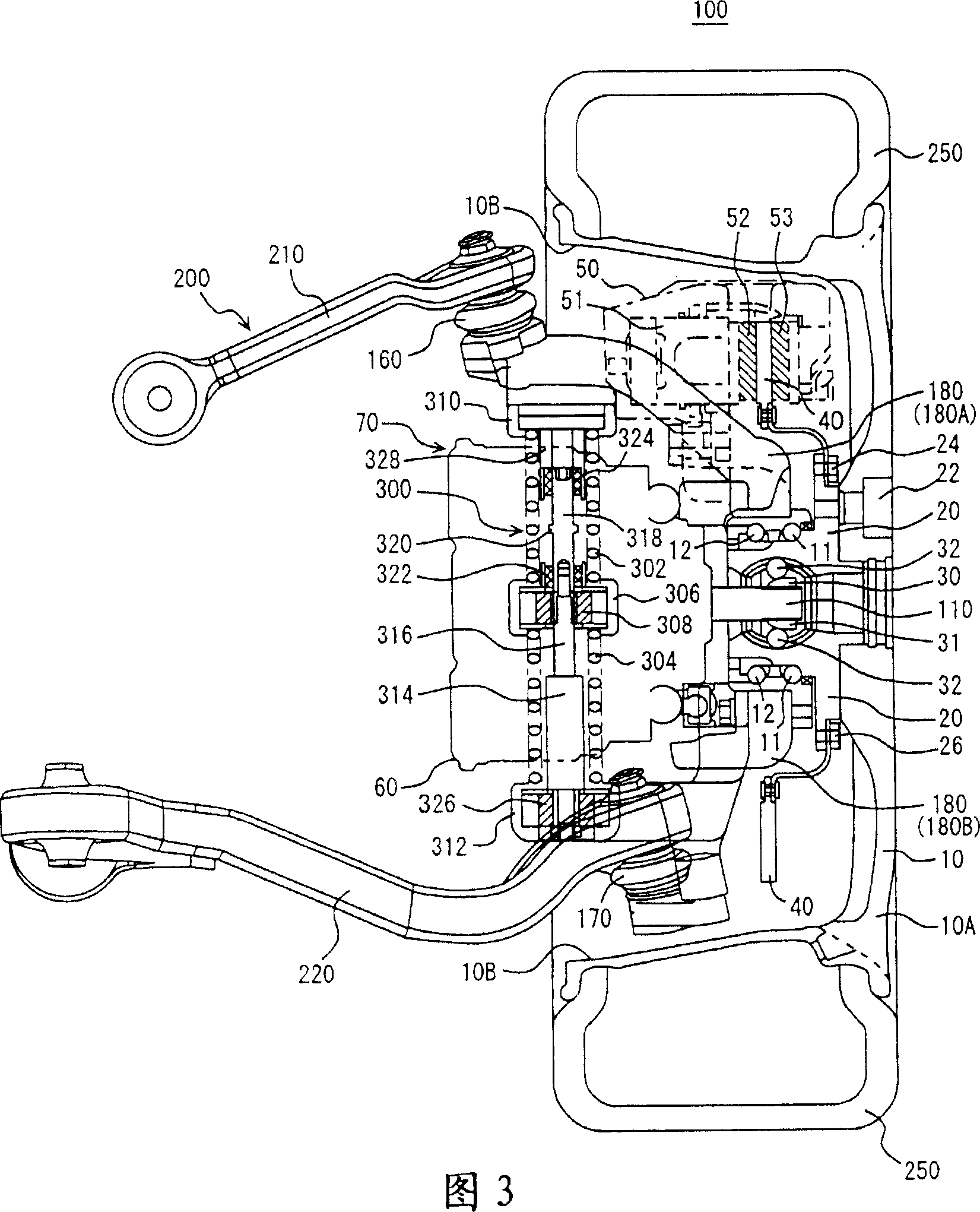

no. 2 example

[0067] Next, a wheel supporting device of a second embodiment of the present invention will be described. Compared with the structure of the wheel support device 200 according to the first embodiment described above, the wheel support device according to the present embodiment is different in the structure of the shock absorber 314 and also differs in that instead of the buffer members 332 and 334, It includes cushioning members 332 and 334 . In other respects, its structure is the same as that of the wheel support device 200 according to the above-mentioned first embodiment. They are denoted by the same reference numerals, and their functions are the same. Therefore, detailed description thereof will not be repeated here.

[0068] The wheel supporting device 200 involved in the present invention is characterized in that it includes: a housing 60 vibrating with the vibration of the in-wheel motor 70; a steering knuckle 180 that limits the vibration of the motor by contacting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com