Control device of exhaust gas by-pass valve

A wastegate valve and control device technology, applied in the direction of machines/engines, internal combustion piston engines, mechanical equipment, etc., can solve problems such as poor reliability and unstable work performance, and achieve the goal of increasing the duty cycle and boosting pressure Effect

Inactive Publication Date: 2007-05-09

CHERY AUTOMOBILE CO LTD

View PDF0 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

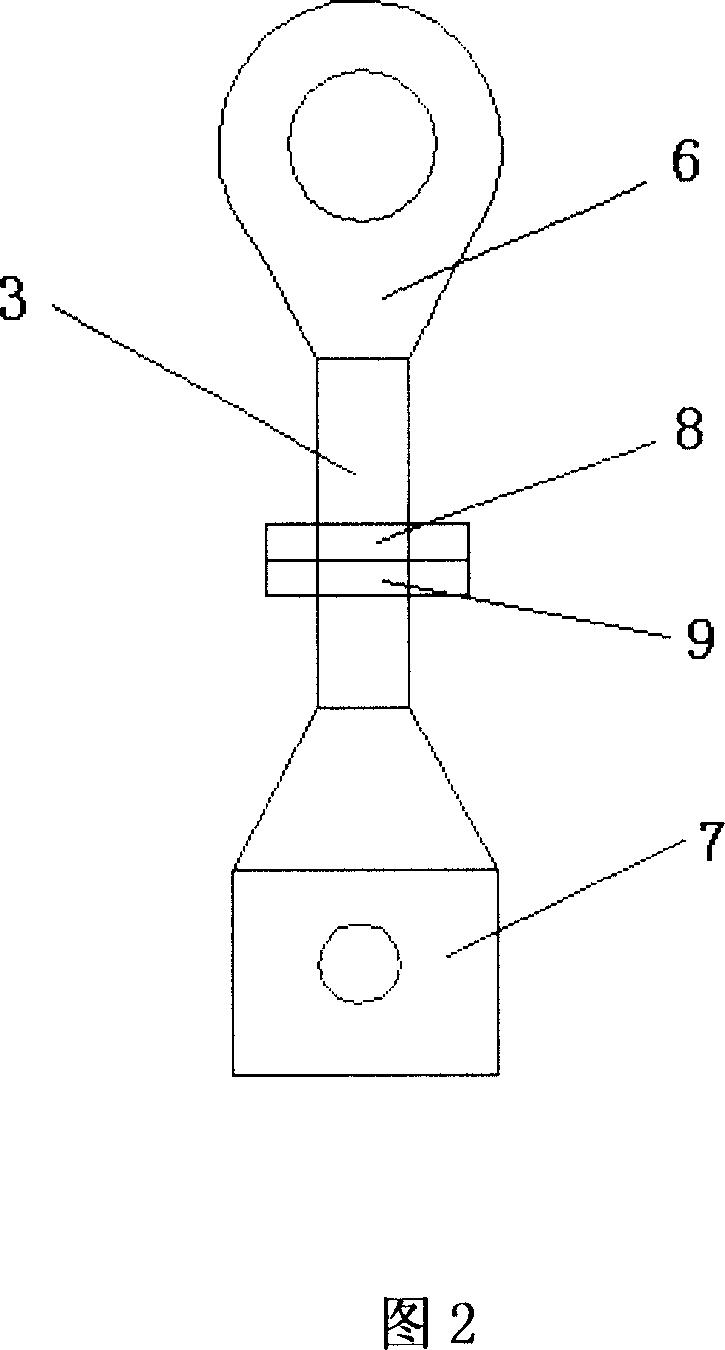

[0005] In order to solve the technical problem of unstable working performance and poor reliability of the actuator with diaphragm spring in the waste gas bypass control device when the stroke is large, the present invention provides a waste gas bypass valve control device, which not only protects the diaphragm spring The actuator can greatly adjust the boosting capacity of the supercharger, improve the plateau compensation ability of the engine and the overall performance of the engine, and the performance is stable and reliable

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

Description

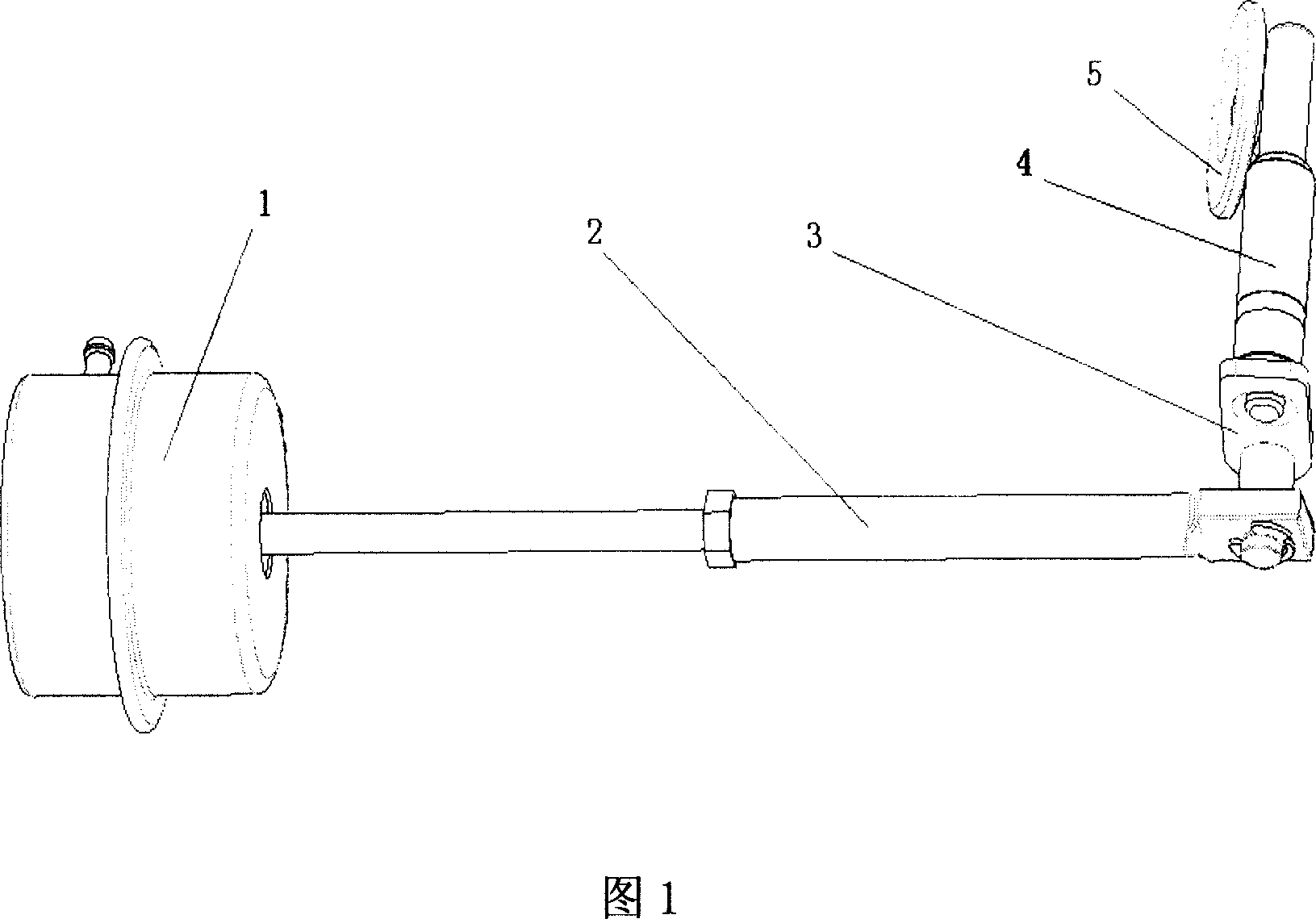

technical field [0001] The invention relates to an engine waste gas bypass control device, in particular to an engine waste gas bypass control device with a turbocharger. Background technique [0002] At present, with the increasing requirements for emission, fuel consumption and power characteristics, it is undoubtedly the most feasible solution to use supercharging to improve the performance of the engine in all aspects. Engine supercharger control is divided into two strategies: wastegate control and variable area control. Although the variable section is advanced in technology, due to the limitation of nozzle material and reliability, it will be difficult to be used in high exhaust temperature engines such as small gasoline engines for a long time in the future. The working principle of the wastegate is to open a direct channel between the turbine end of the turbocharger, between the exhaust gas inlet and the gas outlet, without passing through the turbine, and add a va...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F02B37/12

CPCY02T10/144Y02T10/12

Inventor 甘云强

Owner CHERY AUTOMOBILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com