A gas turbine axial force control device and control method thereof

A gas turbine and control device technology, which is applied to gas turbine devices, jet propulsion devices, mechanical equipment, etc., can solve the problems of high pressure value, reduced life of control valve, gas leakage, etc., and achieves simple method, guarantees smoothness, and meets high automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

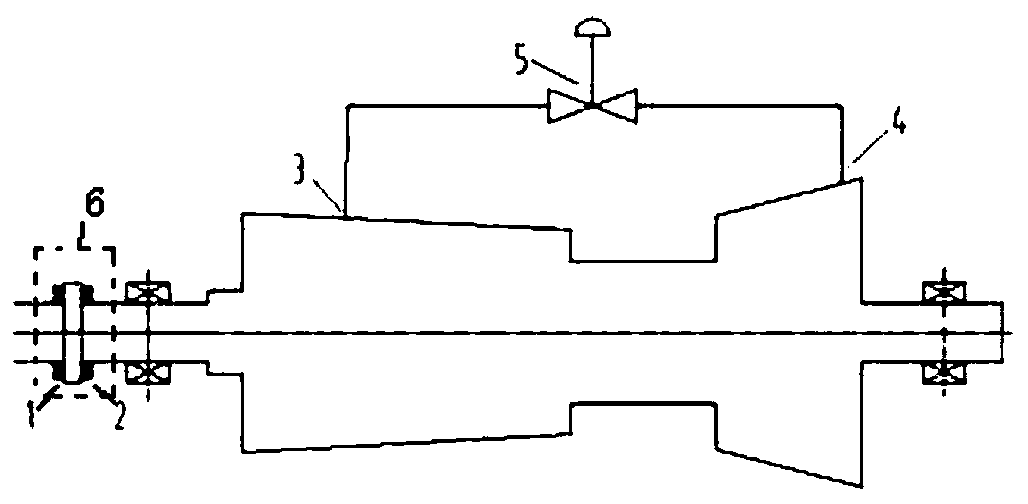

[0039] A gas turbine axial force control device provided by an embodiment of the present invention, such as figure 1 As shown, a thrust bearing 6 is arranged in the bearing assembly, and the thrust bearing 6 includes an auxiliary thrust bearing 1 and a main thrust bearing 2. When a gas turbine exceeds about 70% of the rated load in winter, the main thrust bearing 2 in the thrust bearing 6 The bearing axial thrust will exceed its design axial thrust value of 17.7×10 4 N, at this time, the unloading regulating valve 5 needs to be opened, and the compressor pumping air is introduced into the unloading chamber to control the pressure of the main thrust bearing 2 in the thrust bearing 6 within its rated range.

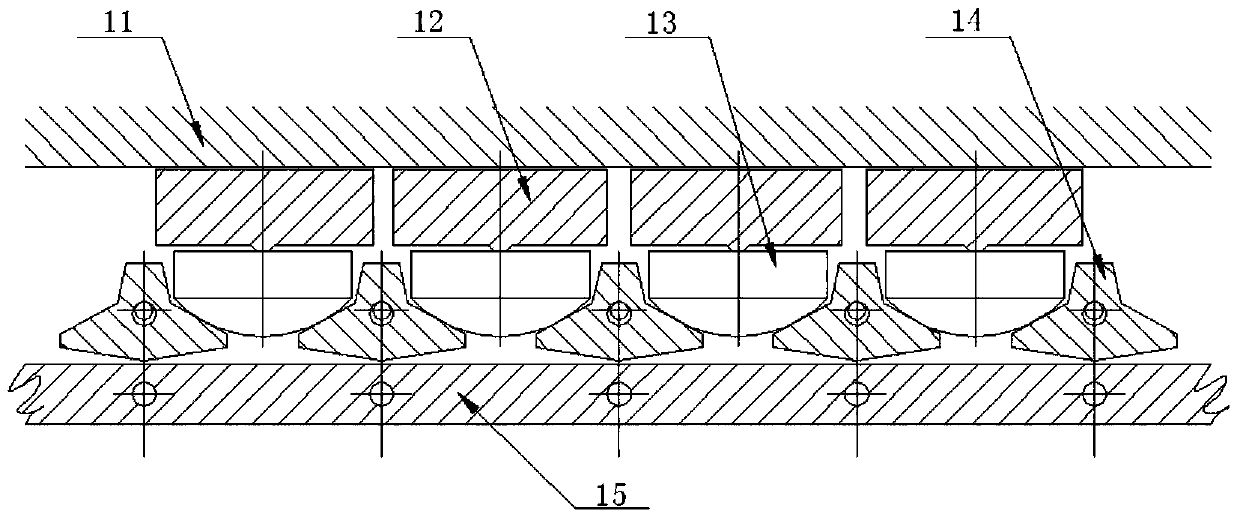

[0040] The control device includes a pressure sensor arranged on the thrust bearing 6, such as figure 2 As shown, the thrust bearing 6 includes a thrust disc 11, a thrust pad 12, a support disc 13, an equalizer plate 14 and a seat ring 15, wherein the thrust pad 12 is in ...

Embodiment 2

[0046]A control method of a gas turbine axial force control device provided in an embodiment of the present invention includes the following steps:

[0047] S1. The pressure sensor detects the pressure measurement value according to the force of the thrust bearing;

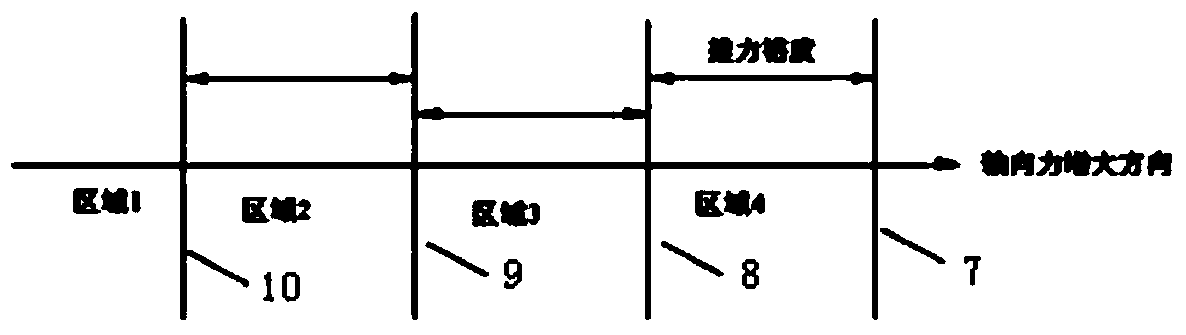

[0048] S2. In order to improve the accuracy of the measured pressure, the pressure measurement value is transmitted to the optimization module, and the optimal pressure value is selected by the optimization module; wherein, the optimization module is realized by software. Four axial force pressure sensors are installed on the main thrust bearing 2 side, and the pressure value is selected through the optimal scheme. The controller has a programming function, and the optimization module is realized by programming, that is, software. The simpler optimization method is: calculate the square of the difference between each pressure value and the other three pressure values one by one and add them up, and select the sm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com