Color light filter base plate and LCD

A technology of color filters and substrates, which is applied in the directions of instruments, optics, nonlinear optics, etc., and can solve the problems that the opening ratio and the uniform height spacers cannot be completed at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

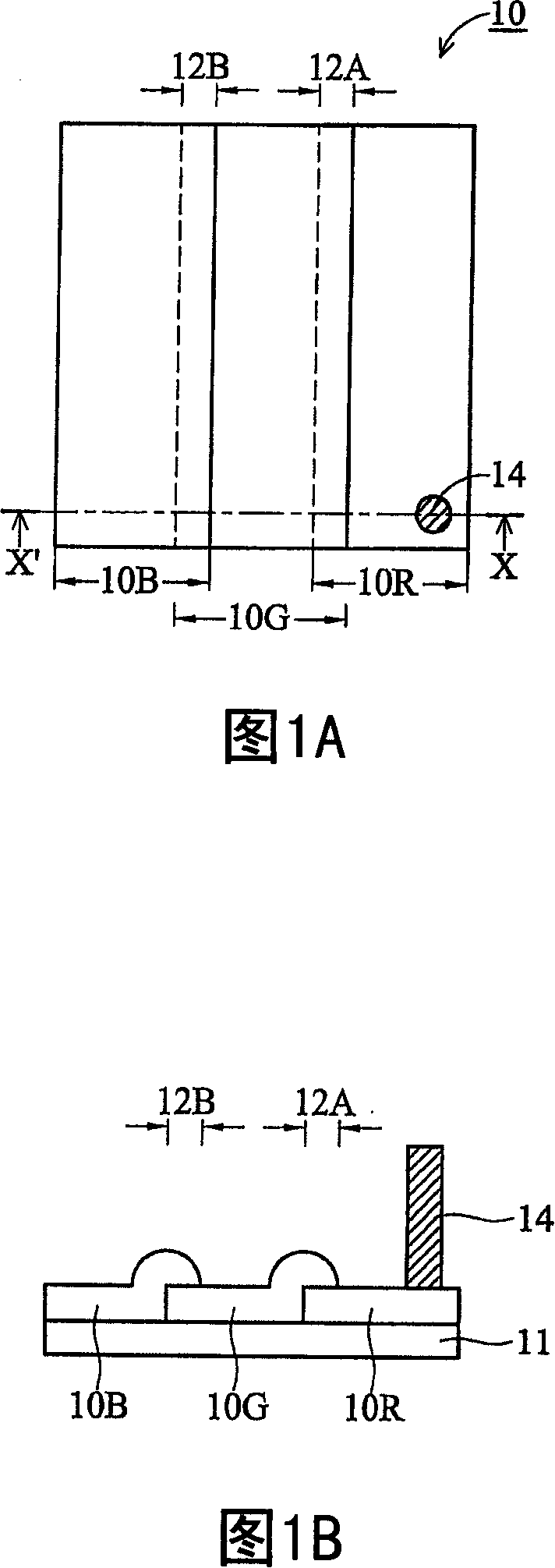

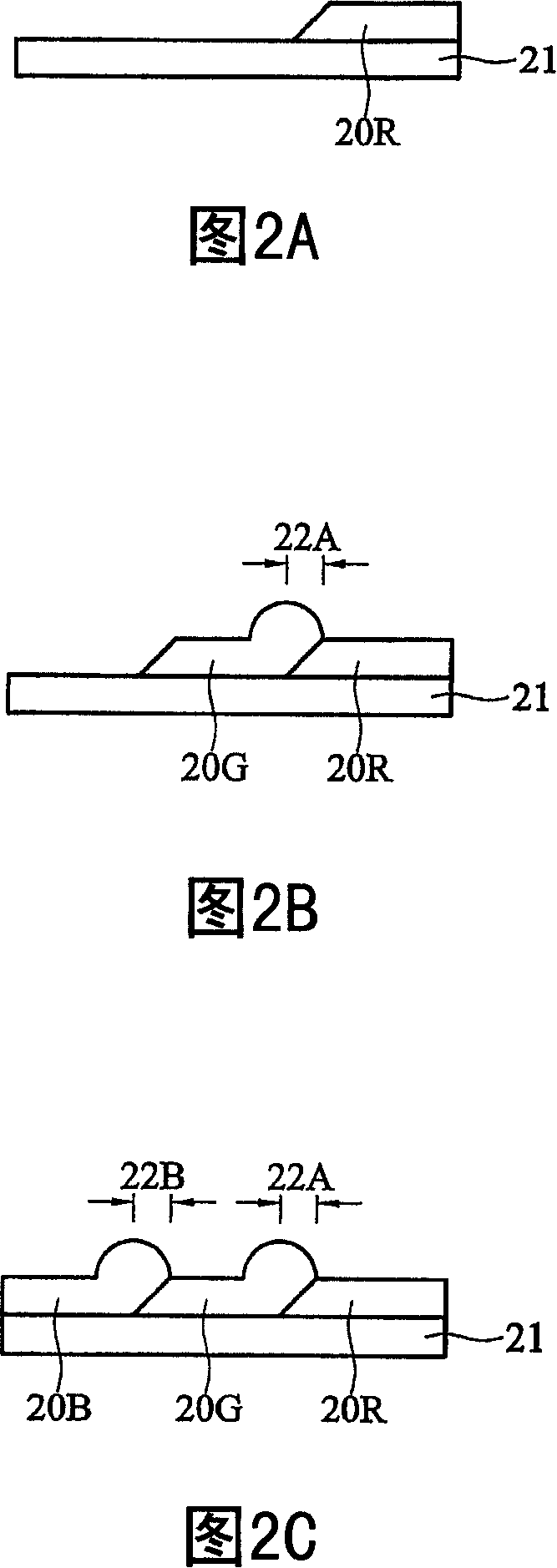

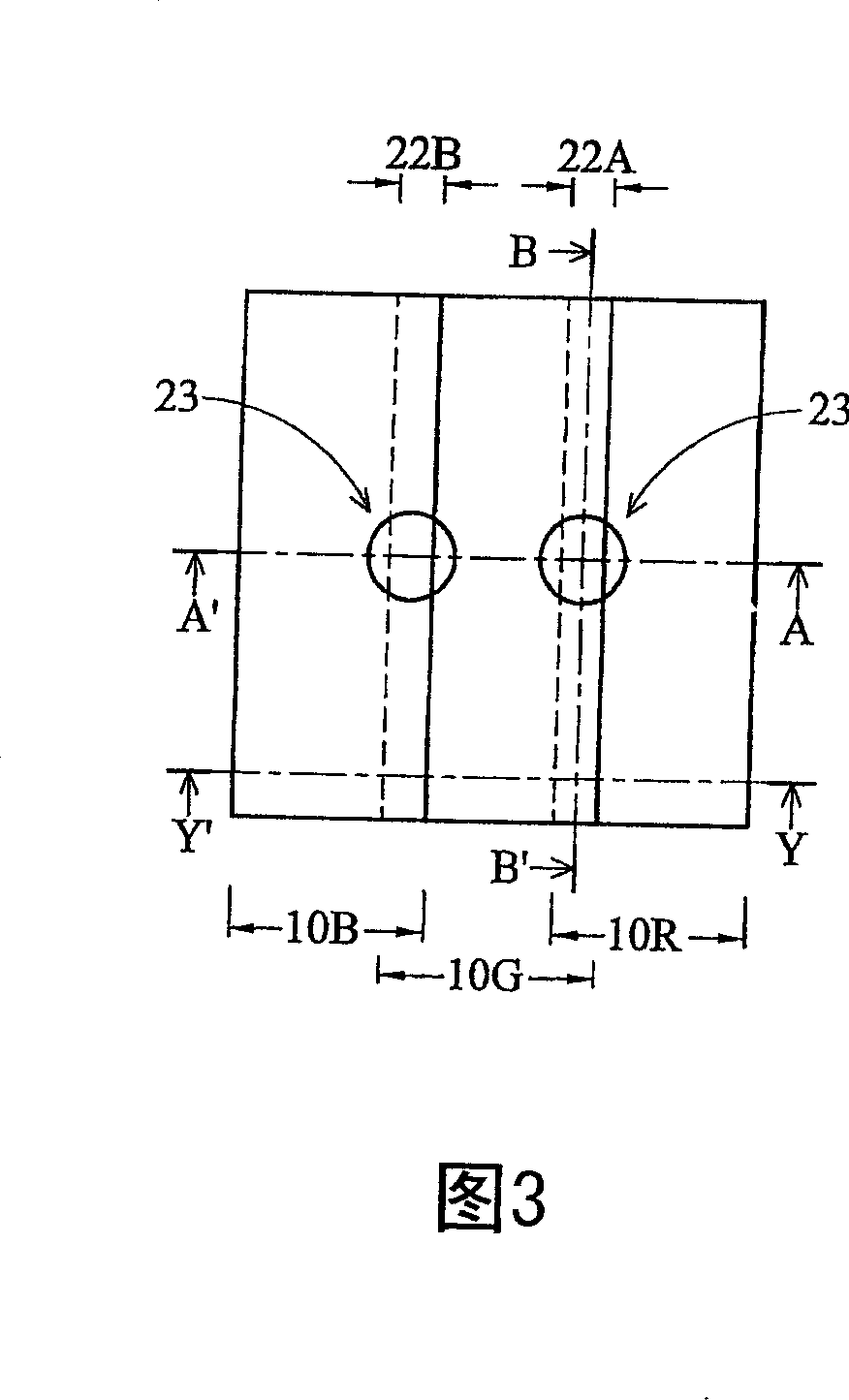

[0040] 2A-2C show the manufacturing process of the color filter substrate in a preferred embodiment of the present invention. First, a red color filter 20R is formed on the substrate 21 . The forming method may be to spin coat a photosensitive resin containing red pigment on the substrate 21 . In a preferred embodiment, the substrate 21 is made of plastic, resin, glass and other materials. Then, the color filter 20R is patterned by a photolithography process. Next, as shown in FIG. 2B , a green color filter 20G is formed on the substrate 21 , and its formation method or composition may be similar to that of the red color filter 20R. In FIG. 2C, a blue color filter 20B is formed on a substrate 21 in the same manner as described above. As shown in FIG. 2C , part of the color filter 20G remains on the 20R to form a color overlapping region 22A. Similarly, part of the color filter 20B remains on the 20G to form a color overlapping region 22B. The order of forming the color fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com