Torque wrench with sensor

A torque wrench and sensor technology, applied in the field of wrenches, can solve problems such as buckling, inability to correctly sense wrench bending deformation and torque value, loss of combination relationship, etc., and achieve the effect of guaranteeing accuracy and reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

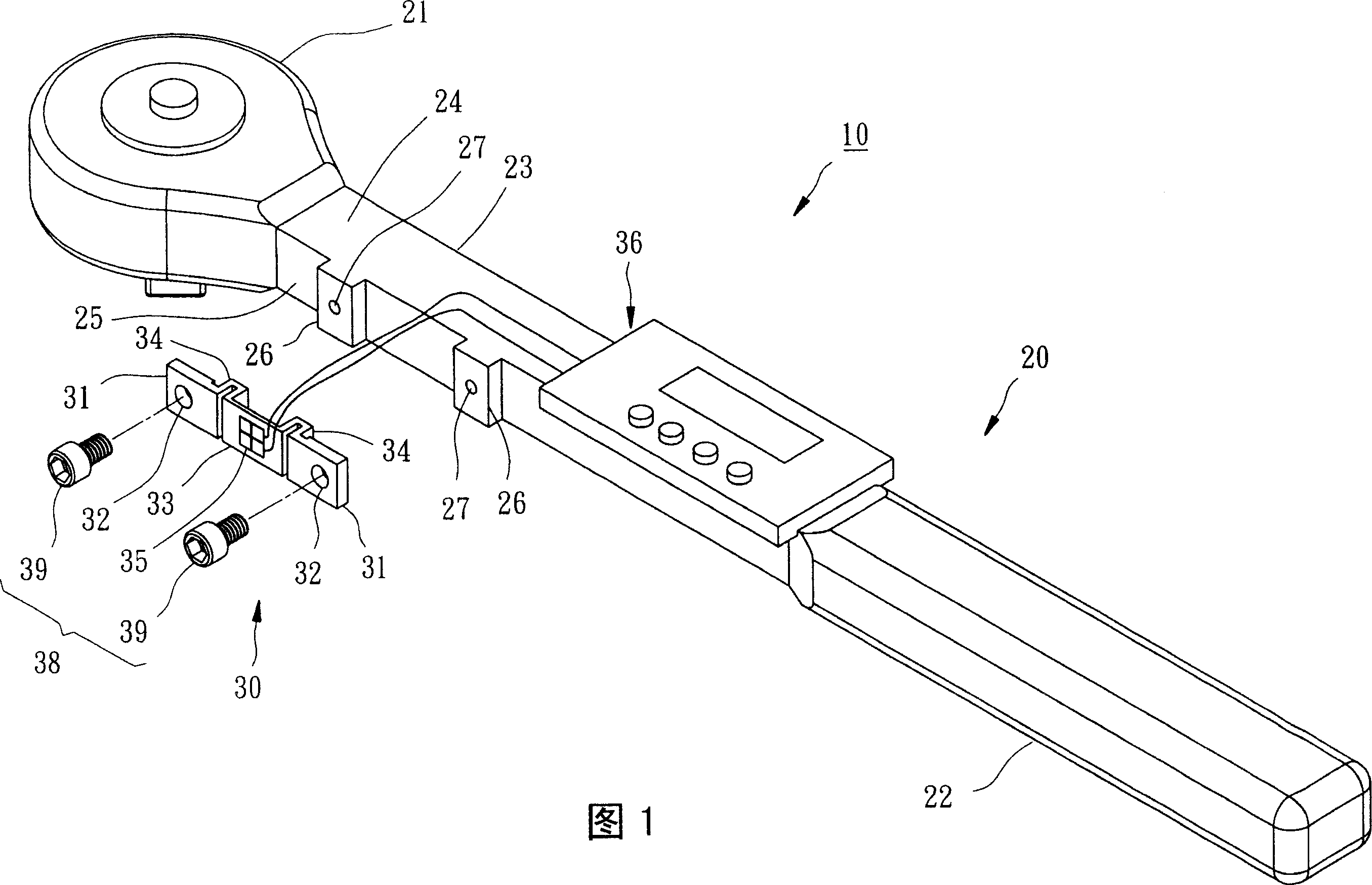

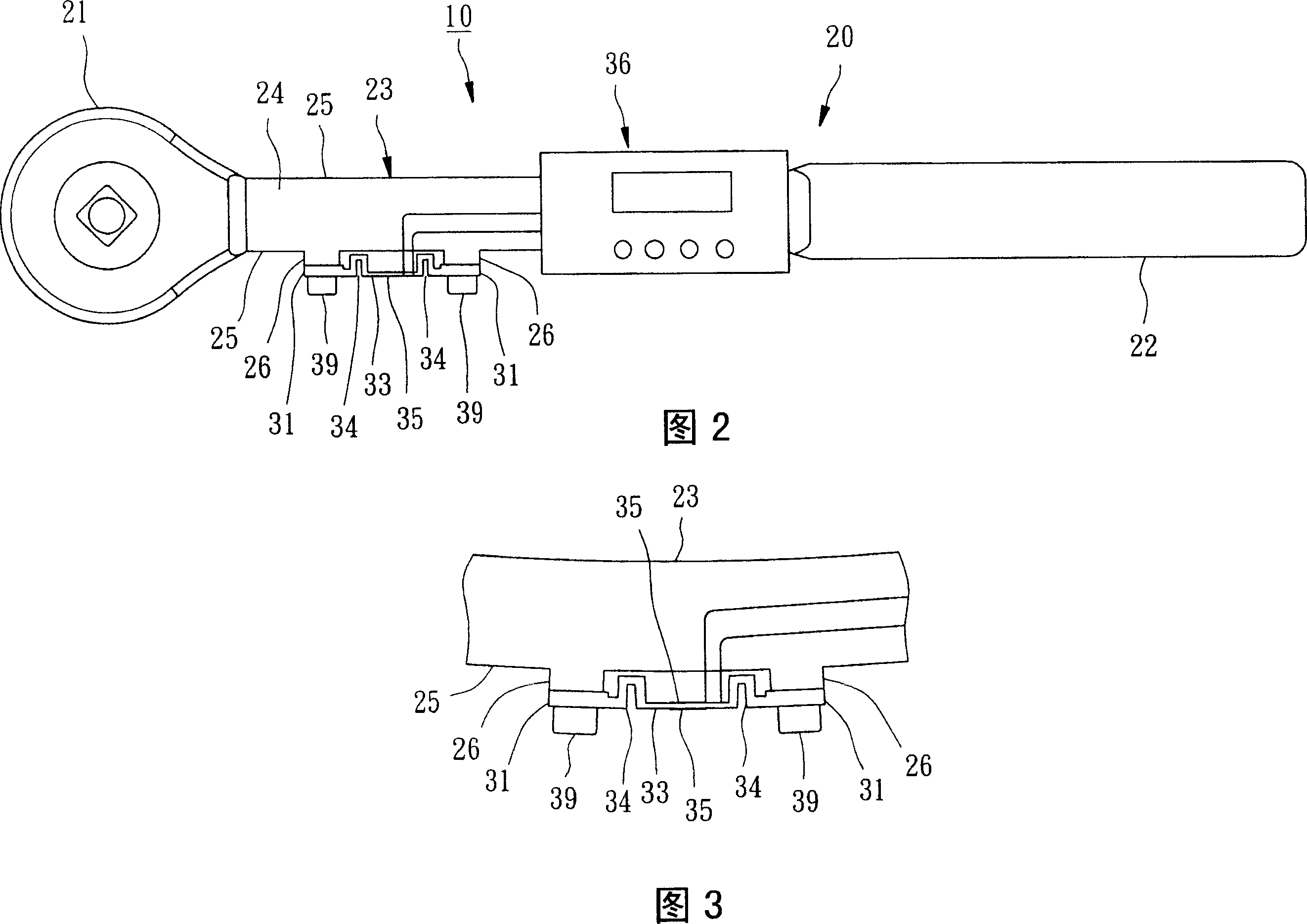

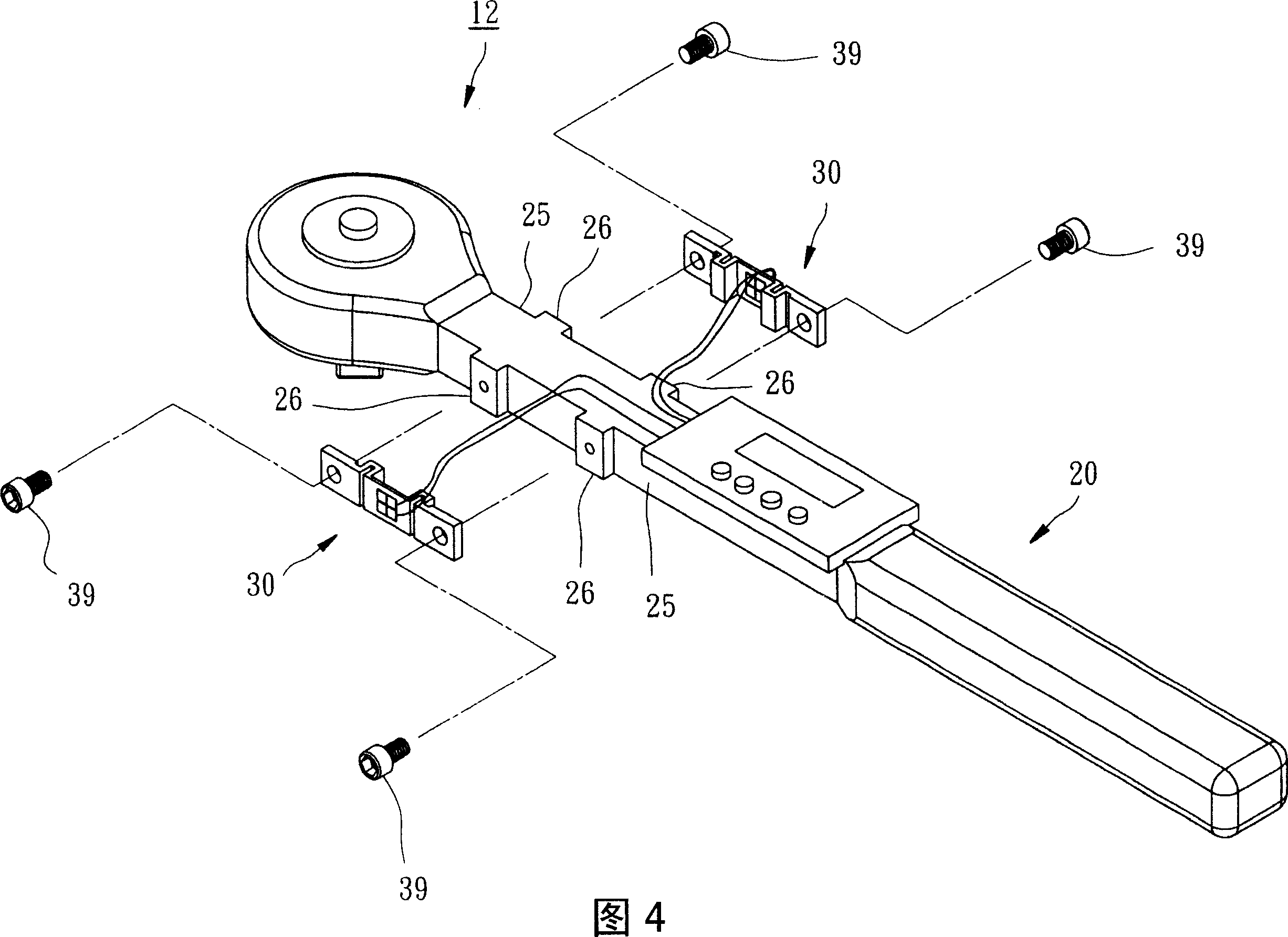

[0067] Referring to FIG. 1 and FIG. 2 , a wrench 10 with a sensor 30 is provided for the first preferred embodiment of the present invention. The wrench 10 includes a body 20 , a sensor 30 , and a fixing device 38 . The body 20 is in the shape of a rod. One end of the body 20 has a head 21 for connecting the sleeve, and the other end has a handle 22 that can be turned. The head 21 and the handle 22 are integrally connected with a A middle portion 23, the middle portion 23 has a top wall 24 and two side walls 25 that are located on two sides of the top wall 24, wherein the wall surface of the side wall 25 has two positioning portions 26 at a predetermined distance, each positioning portion 26 is from The middle part 23 integrally extends and partially protrudes from the side wall 25 , and each positioning part 26 is provided with a screw hole 27 recessed from the end surface.

[0068] As shown in Figure 3, the sensor 30 is in the shape of an elongated plate, and the material of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap