Electric vacuum cleaner

A vacuum cleaner and electric technology, which is applied in the installation of suction nozzles and electrical equipment, etc., can solve the problems of no dust being detected, no display of the vacuum cleaner, and inability to know whether the vacuum cleaner is in a normal state or in a fault state.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

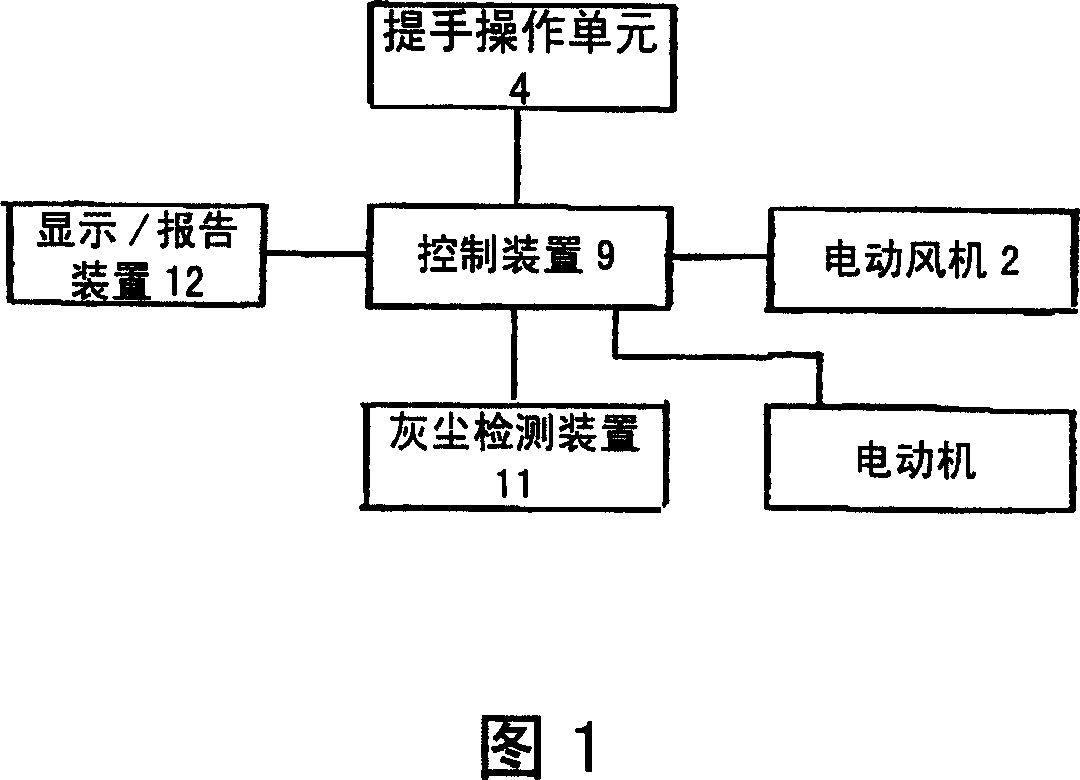

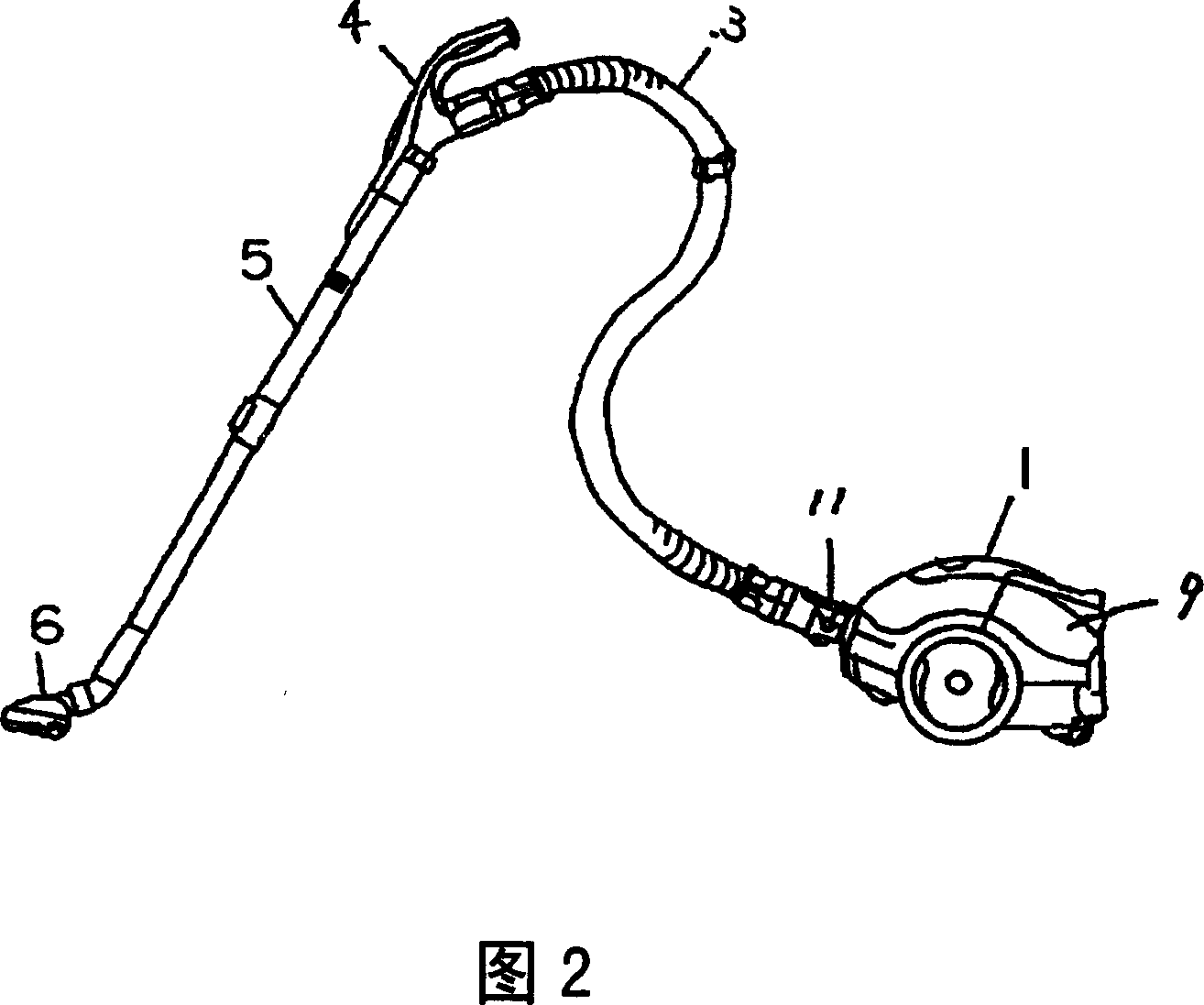

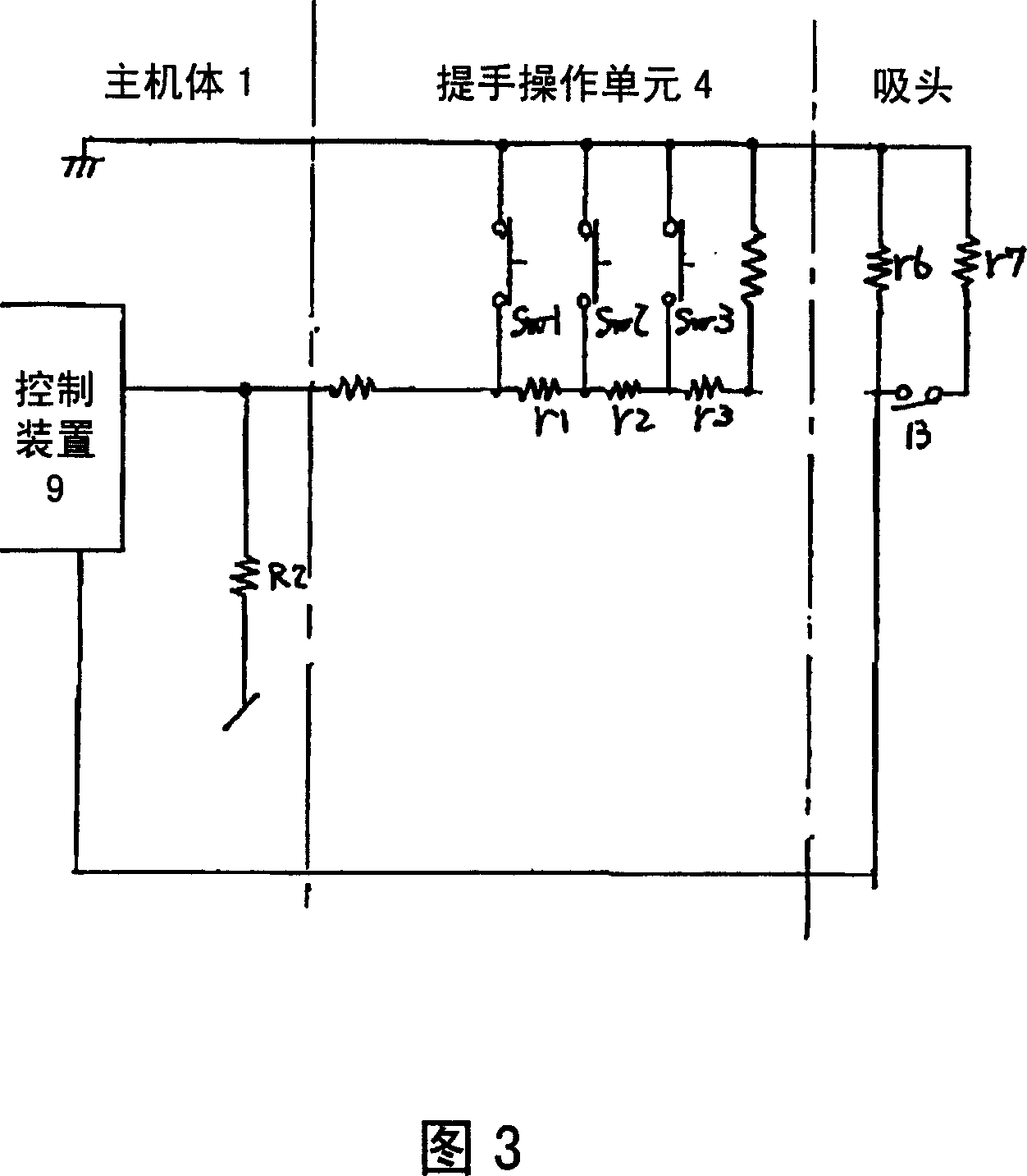

[0022] Fig. 1 is a circuit block diagram of an electric vacuum cleaner in the first embodiment of the present invention, and Fig. 2 is a schematic diagram of the appearance of the electric vacuum cleaner.

[0023] In Fig. 2, 1 is the body of the electric vacuum cleaner, which is equipped with an electric fan 2 for generating suction and collecting dust into the dust collection chamber (not shown in the figure). 3 is the handle operation unit 4 and the body of the vacuum cleaner 1 connected hose, the handle operating unit 4 is provided with operation switches (operating positions) such as "strong", "automatic" and "weak", which can switch the strength of attraction of the electric fan 2. 6 is the suction head that contacts with the ground, thereby the dust etc. on the surface to be cleaned are sucked up, and the inside of the suction head 6 is provided with a rotating brush (not shown) for sweeping up the dust on the surface to be cleaned and A rotating brush motor (not shown i...

Embodiment 2

[0036] Fig. 7 is a schematic diagram showing an example of the handle operation unit 4 and the display / report device 12 in the second embodiment of the present invention. Here, the same parts as those in the above-mentioned first embodiment are given the same symbols, and their descriptions are omitted.

[0037] As shown in FIG. 7, when there is no signal input in the dust detection device 11, the display / reporting device 12 is usually in an off state, and if the dust detection device 11 detects dust, it displays in different states such as lighting. In the vacuum cleaner of the present invention, when the phase is at 550W, the current detection device 14 detects the air volume through the current flowing through the electric fan 2 . When detecting and judging the air volume, considering factors such as the stability of the current change, it is best to perform detection for about 5 seconds. Within these 5 seconds, if there is a signal output from the dust detection device 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com