Multi-sealing easy-to-maintenance efficient double-suction centrifugal pump

An easy-to-maintain, centrifugal pump technology, applied in the field of centrifugal pumps, can solve the problems of poor airtightness, difficult processing of long shaft sleeves, complex structure, etc., to improve cavitation performance, improve impeller inlet flow state, and increase inlet area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

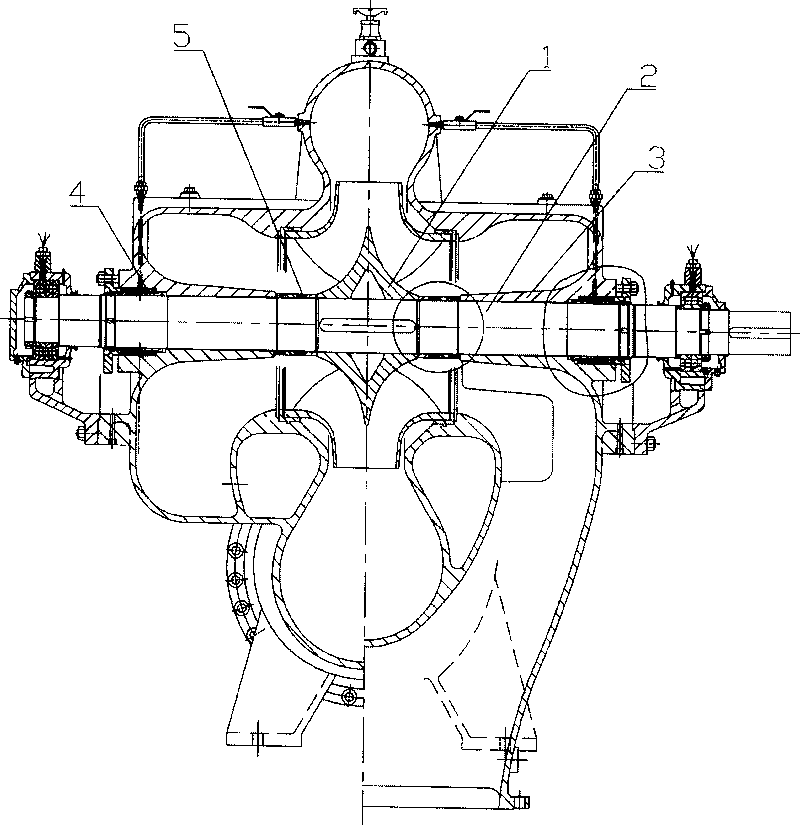

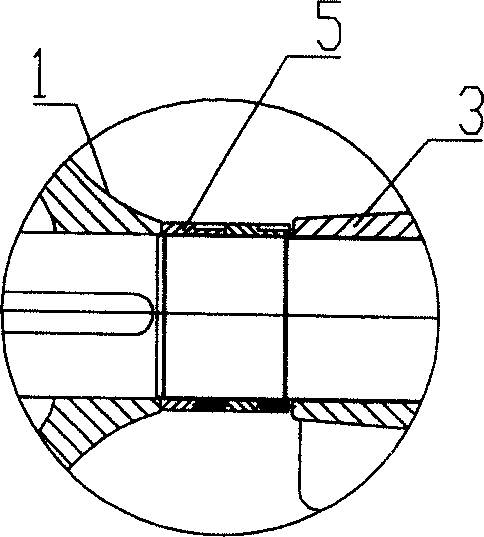

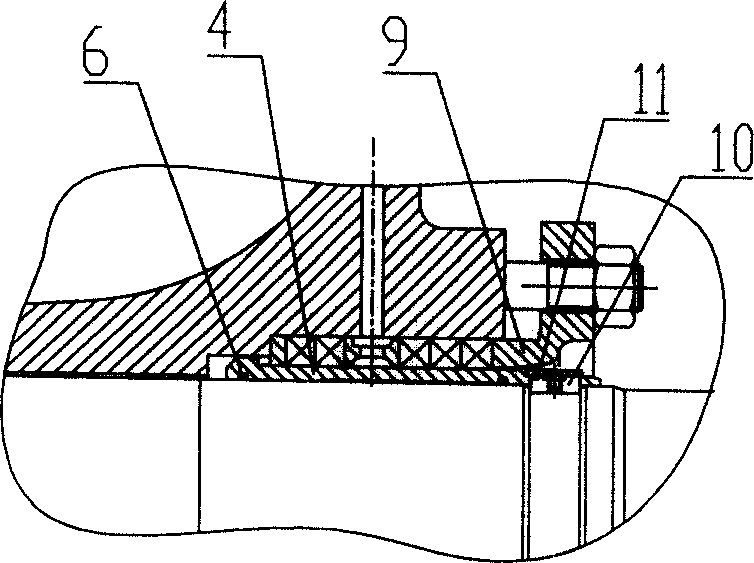

[0018] Such as figure 1 , 2 The first embodiment of the present invention shown in Figure 3 is a multi-seal, easy-to-maintain, high-efficiency double-suction split centrifugal pump with an impeller 1, a pump shaft 2, and a pump body 3. The impeller 1 and the pump shaft 2 are connected by keys, Installed together in the pump body 3. A section of thread is provided on the pump shaft 2 on both sides of the impeller hub, and the impeller nut 5 for fixing and adjusting the center of the impeller 1 is installed on it. A packing shaft seal device is installed between the pump shaft 2 and the pump body 3. 5. The shaft sleeve 4 and the impeller 1 do not share keys, do not touch, and do not interfere. The shaft sleeve 4 and the pump shaft 2 are sealed with two O-rings 6; the shaft sleeve 4 is fixed with the positioning key 10 and the sleeve pressing ring 11; the shaft sleeve 4 and the pump body 3 are sealed with a packing shaft seal device 9 seal.

[0019] Such as Figure 4 In order to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com