Control panel assembly hook for drum washing machine

A drum washing machine and control panel technology, which can be applied to other washing machines, washing devices, textiles, and paper making, etc., can solve problems such as connection failure and deformation of hooks 8

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

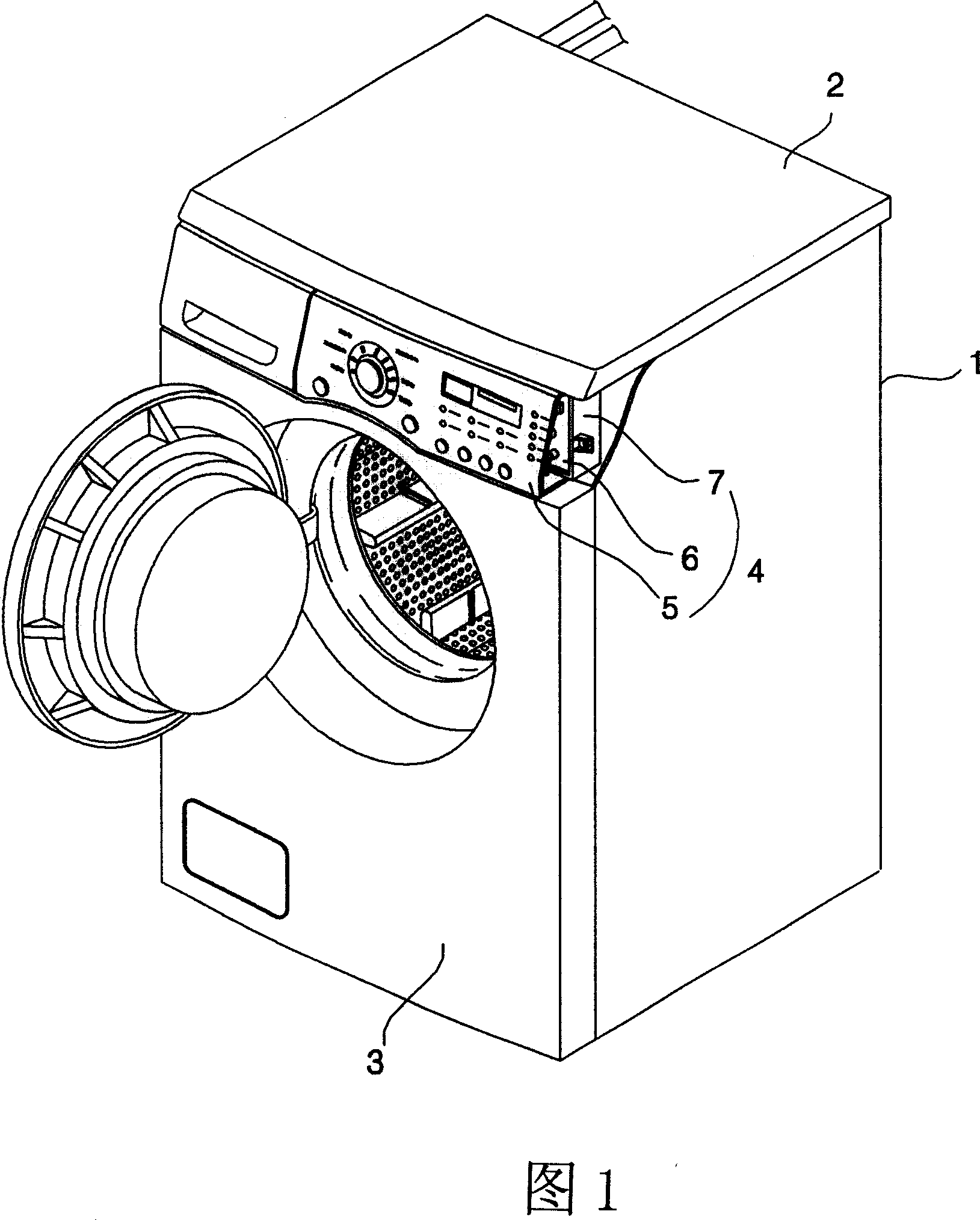

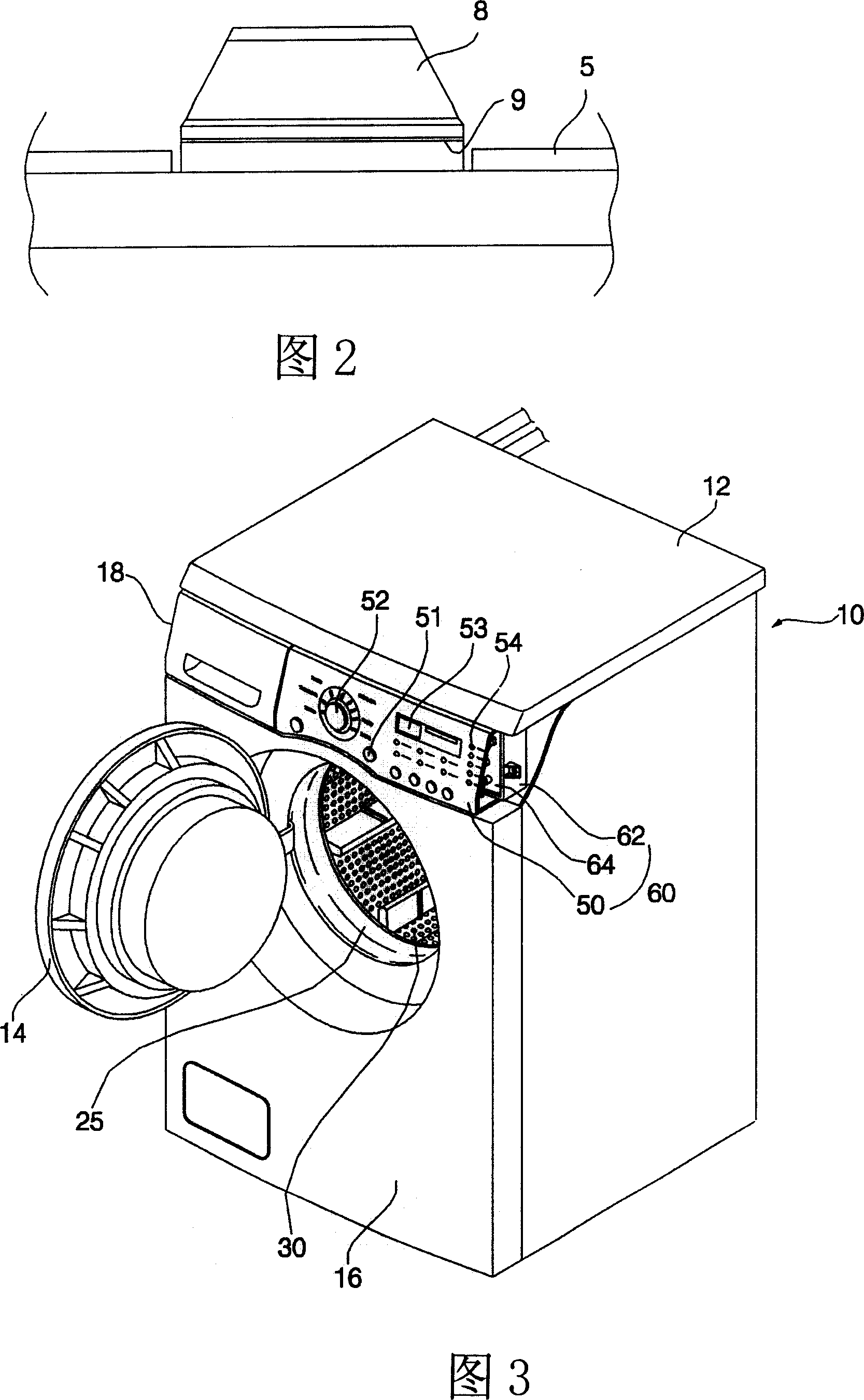

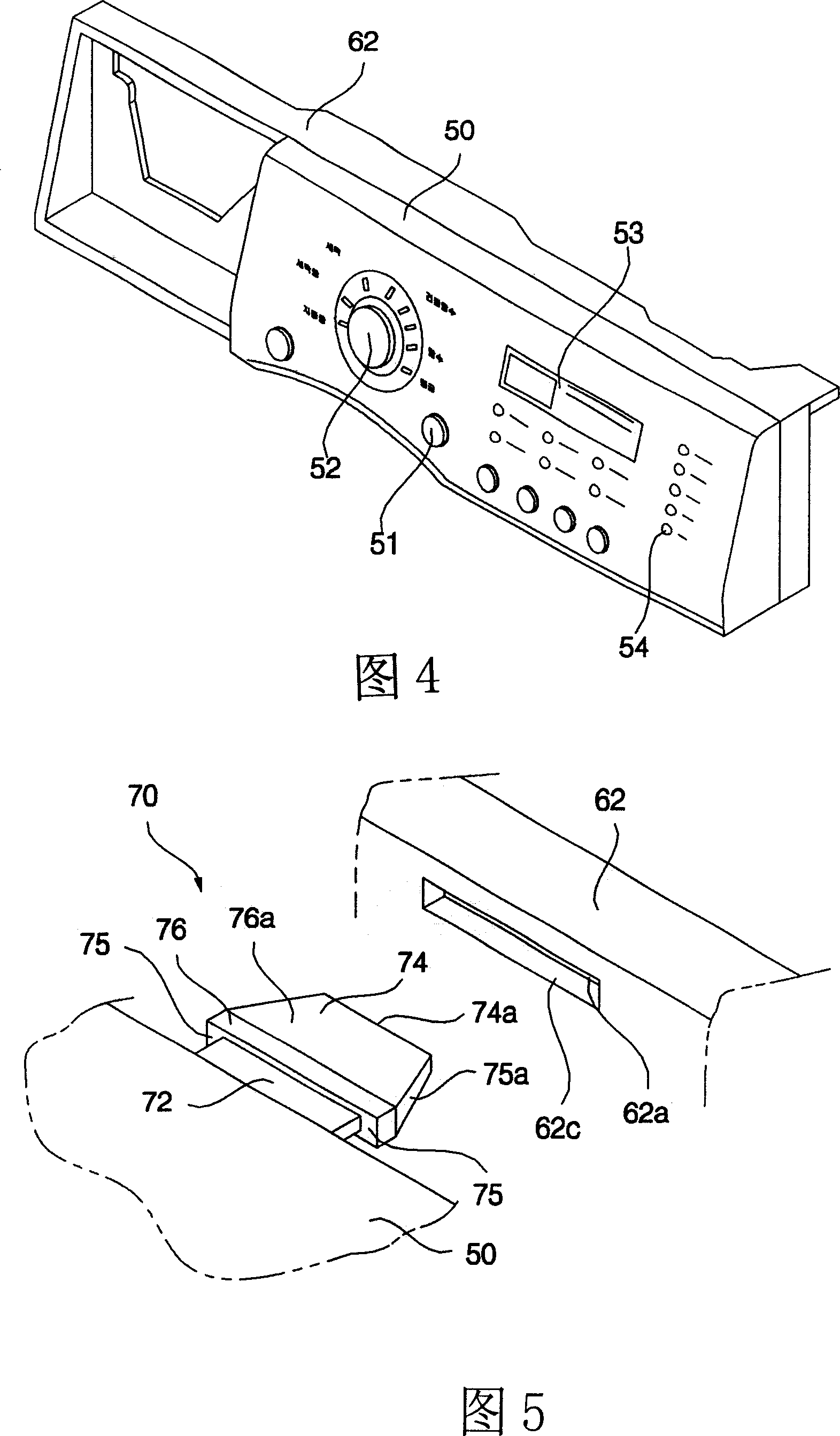

[0031] As shown in Figure 3, the front-loading washing machine of the present invention is made up of following parts, promptly forms the casing 10 of the outer shape of front-loading washing machine; The bucket (not shown) that is installed and fixed in the inside of above-mentioned casing 10; Rotatable drum 30; installed in the rear of the above-mentioned bucket, and connected to the above-mentioned drum through the above-mentioned bucket, thereby driving the motor (not shown in the figure) of the above-mentioned drum 30 to make it rotate; installed in the front of the above-mentioned cabinet 10, for A control panel assembly 60 that controls various components of the drum washing machine described above.

[0032] Above the above-mentioned cabinet 10, a top cover 12 capable of covering the top of the above-mentioned cabinet 10 is installed, and in the front of the above-mentioned cabinet 10, a cabinet cover 16 having a hole for installing the door 14 is installed.

[0033] On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com