Special-shaped building block feed bucket

A technology for feeding hoppers and blocks, which is applied in the direction of supply devices, ceramic molding machines, manufacturing tools, etc., and can solve problems that affect the strength of blocks, not in place, unevenness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

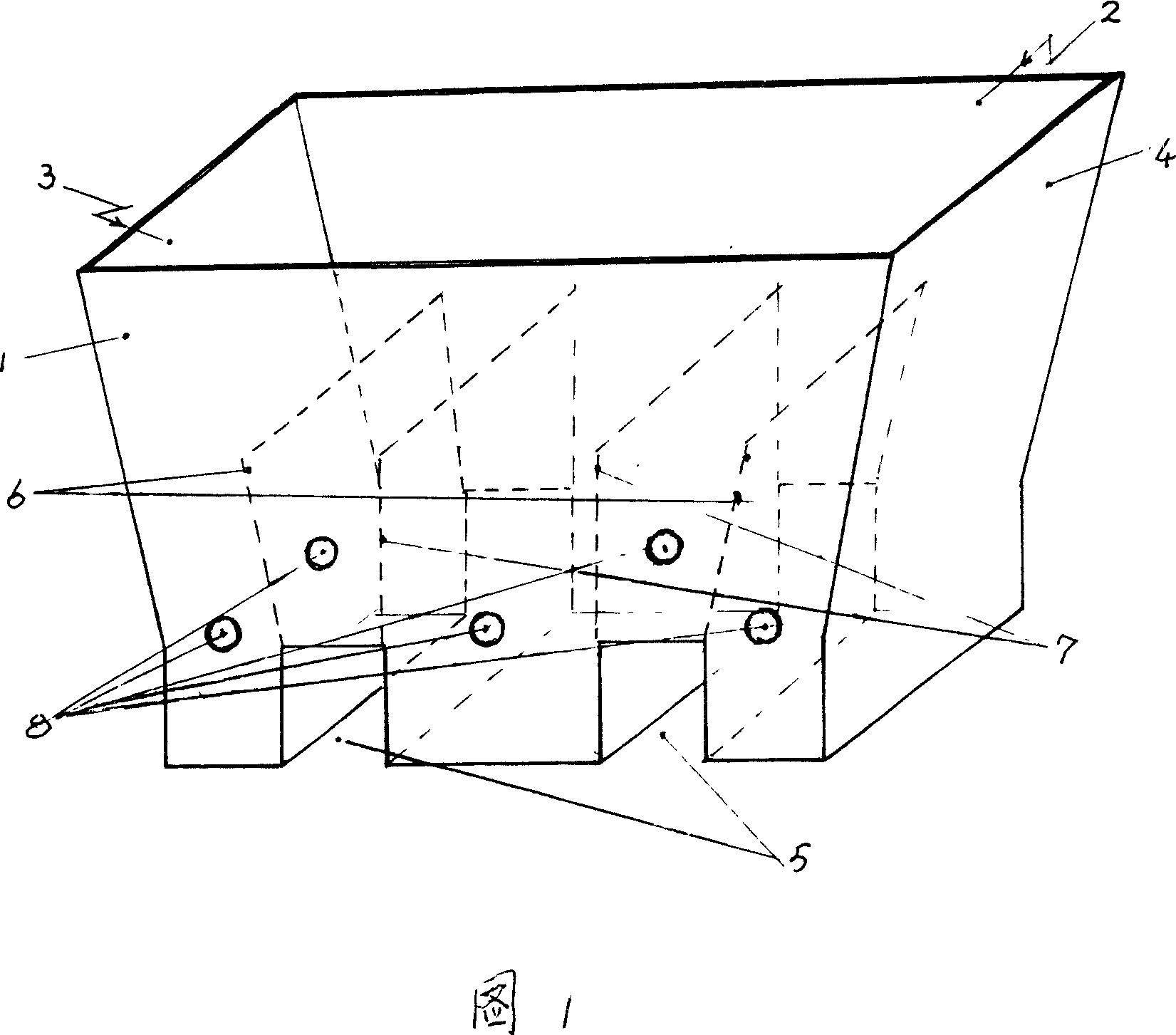

[0007] Example 1. Referring to accompanying drawing 1, make an approximate box-type special-shaped block feeding hopper, which is open up and down, and its front and rear sides 1 and 2 are parallel, and at least one of its lower ends is connected to the special-shaped block. Concave gap 5 that the convex part matches; Extend upwards along the two walls of the concave gap in the feeding hopper to form partitions 6, 7; The top of each discharge port is provided with feeding roller 8, and one end of each feeding roller is connected with the transmission mechanism outside the feeding hopper. Said feeding roller refers to the general apparatus that blades are installed on the rotating shaft, which can push and push the material in the feeding hopper.

[0008] When in use, the above-mentioned feeding hopper is placed on the mother mold of the special-shaped block, and the gap 5 of the feeding hopper is just set on the convex part of the mother mold. When the sandstone concrete is ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com