Sprayer

A technology of spraying device and spraying tube, which is applied in the direction of spraying device and liquid spraying device, which can solve the problems of slow filtering speed and poor filtering effect, and achieve good filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

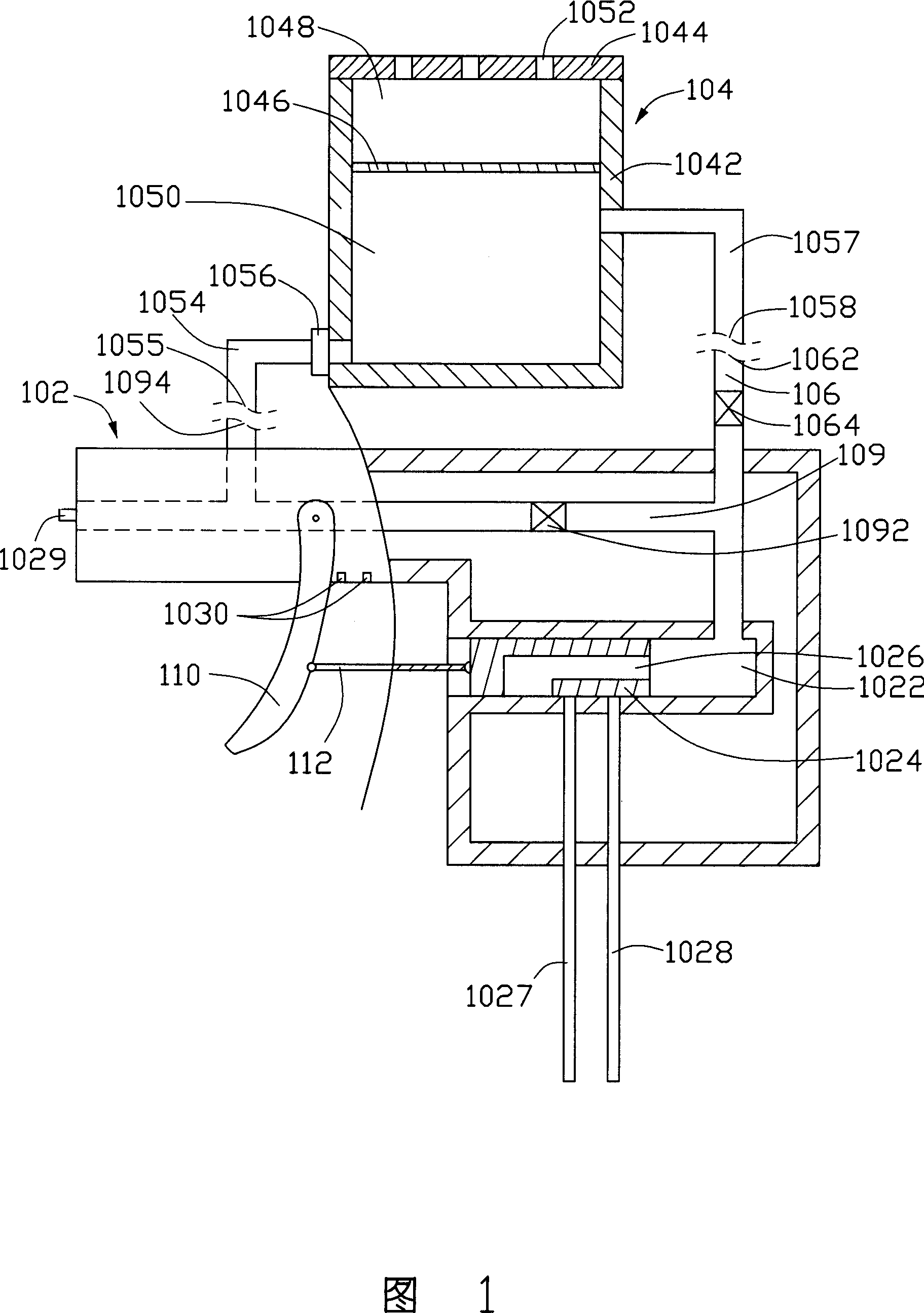

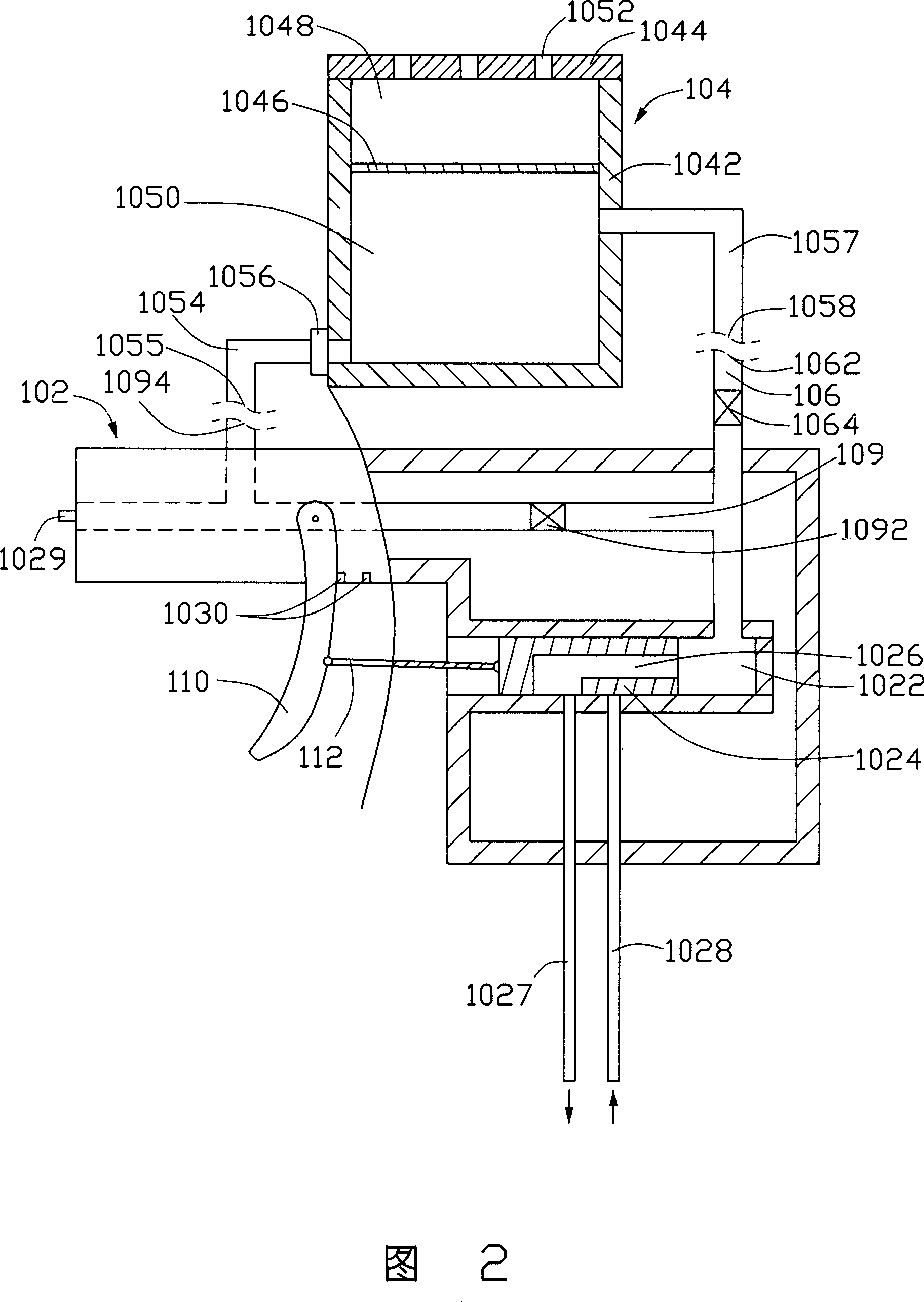

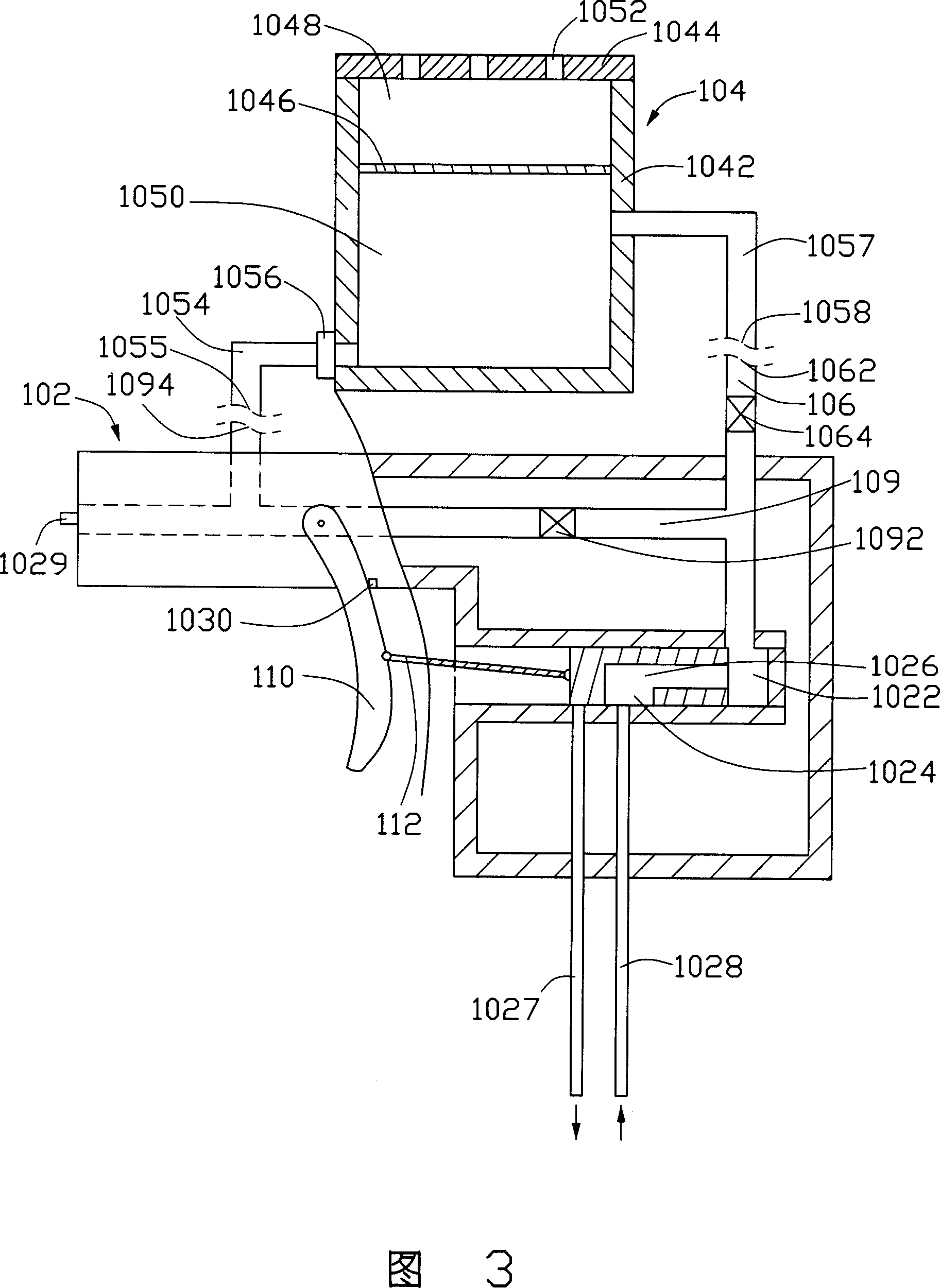

[0010] Referring to FIG. 1 , a spraying device 10 according to a preferred embodiment of the present invention includes a spray gun 102 and a paint tank 104 .

[0011] A transverse channel 1022 is disposed in the spray gun 102 . A piston 1024 is slidably disposed in the transverse channel 1022, and the piston 1024 is in close contact with the inner wall of the transverse channel 1022 so that gas cannot pass through. A horizontal L-shaped vent pipe 1026 is opened in the piston 1024 . One end of the transverse channel 1022 offers an outlet (not marked), and an air delivery pipe 106 and an air injection pipe 109 are all communicated with the outlet, the air delivery pipe 106 includes a first output port 1062, and the air injection pipe 109 includes a first The input port 1094, the air delivery pipe 106 and the air injection pipe 109 are respectively provided with a one-way valve 1064, 1092. Also be provided with an air extraction pipe 1027 and an inflation pipe 1028 in this spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com