Ultrasonic atomizing screen unit

An ultrasonic and screen technology, applied in the field of atomization, can solve the problem that people or objects cannot directly pass through the screen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

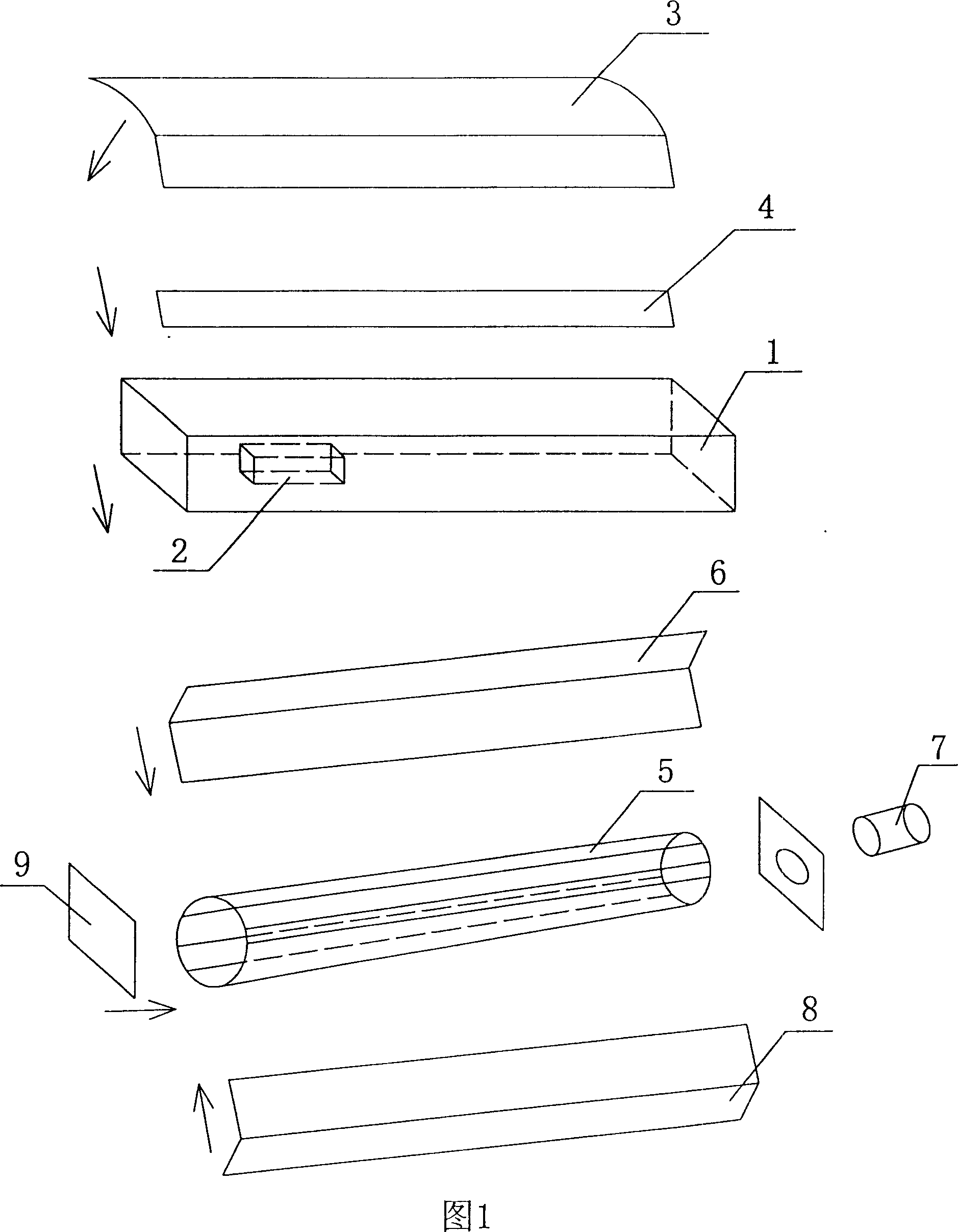

[0012] As shown in Figure 1: it includes an ultrasonic atomizer 2, a water tank 1, a wind wheel 5, a wind wheel housing 6 and a motor 7, the ultrasonic atomizer 2 is installed in an aluminum alloy water tank 1 with water, and the water tank 1 is covered There is a water tank cover 3, and the shape of both ends of the water tank cover 3 is "⌒" shape; the side of the water tank cover 38 connected with the housing 6 is longitudinally equipped with a wind deflector 4; the size of the airflow is controlled by the wind deflector to further control the fog The amount of output; the shell 6 is two 90-degree metal cover plates, the longitudinal inside of the outer shell 6 is a mesh cover 9, the mesh cover 9 is used to protect the wind wheel, and there is a gap above after the two shells 6 are docked; The wheel 5 is contained in the housing 6, and the two ends of the housing 6 are sealed with side plates 10; the right side of the wind wheel 5 passes through the side plate 10 and is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com