Mold unit

A technology of mold and embedded block, applied in the field of plastic injection mold device, can solve problems such as difficulty in height and depth, difficulty in ensuring mold clamping accuracy, etc., and achieve the effect of simplifying cumbersome structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

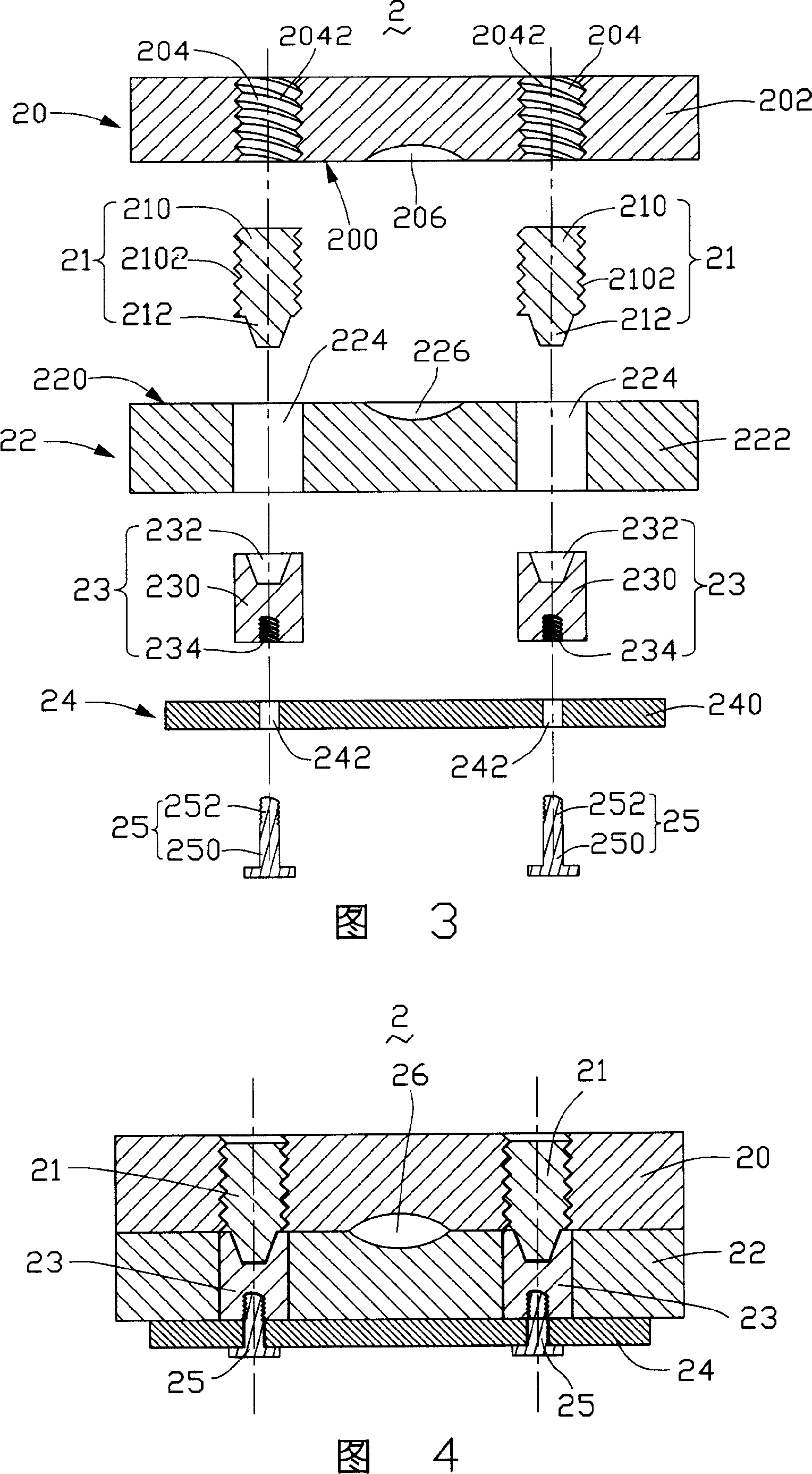

[0017] Referring to FIG. 3 and FIG. 4 , a mold device 2 provided by the first embodiment of the present invention includes an upper module 20 , a first embedded block 21 , a lower module 22 , a second embedded block 23 , a backing plate 24 and bolts 25 .

[0018] The upper module 20 includes a base body 202 , the base body 202 has a first surface and an opposite second surface, and the second surface is the parting surface 200 . The base body 202 also defines a first through hole 204 penetrating through the base body 202 , and the first through hole 204 extends from the first surface to the second surface (ie, the parting surface 200 ). The shape of the first through hole 204 may be cylindrical, and an internal thread 2042 is formed on the inner wall surface constituting the through hole. The upper module 20 also includes an upper mold cavity 206 formed at an end of the upper module 20 close to the parting surface 200 and extending from the parting surface 200 .

[0019] Each...

no. 2 example

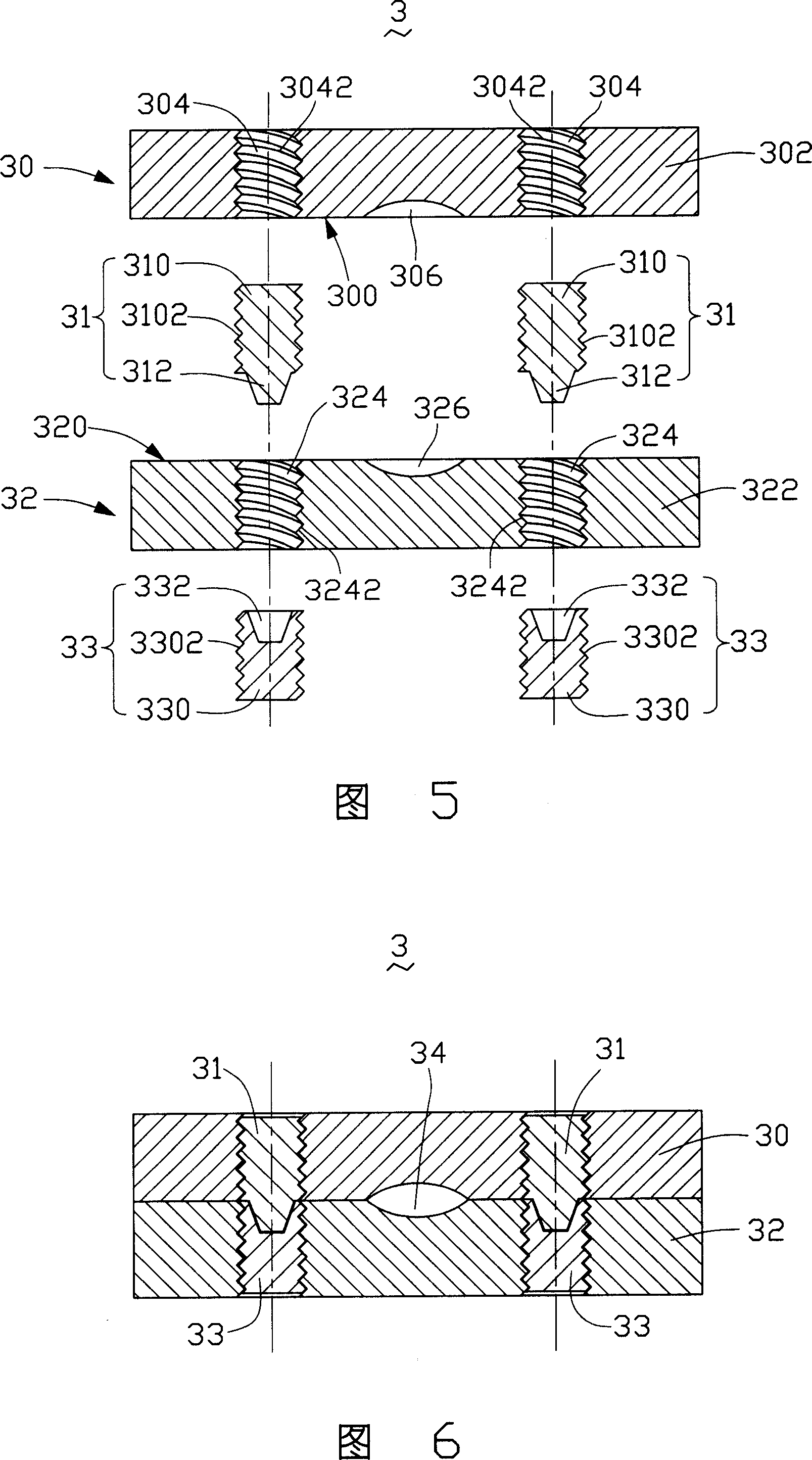

[0028]Referring to FIG. 5 and FIG. 6 , a mold device 3 provided by the second embodiment of the present invention includes an upper module 30 , a first insert block 31 , a lower module 32 , and a second insert block 33 .

[0029] The upper module 30 includes a base body 302 , the base body 302 has a first surface and an opposite second surface, and the second surface is the parting surface 300 . The base body 302 also defines a first through hole 304 penetrating through the base body 302 , and the first through hole 304 extends from the first surface to the second surface (ie, the parting surface 300 ). The shape of the first through hole 304 may be cylindrical, and an internal thread 3042 is formed on the inner wall surface constituting the through hole. The upper module 30 also includes an upper mold cavity 306 formed at an end of the upper module 30 close to the parting surface 300 and extending from the parting surface 300 .

[0030] The first embedded block 31 includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com