Fully automatic permanent magnetic slurry iron remover

A fully automatic, iron remover technology, applied in the direction of magnetic separation, solid separation, cleaning method using liquid, etc., can solve problems such as valve installation congestion, media cage blockage, waste, etc., to reduce maintenance workload and equipment failure efficiency and reduce work costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

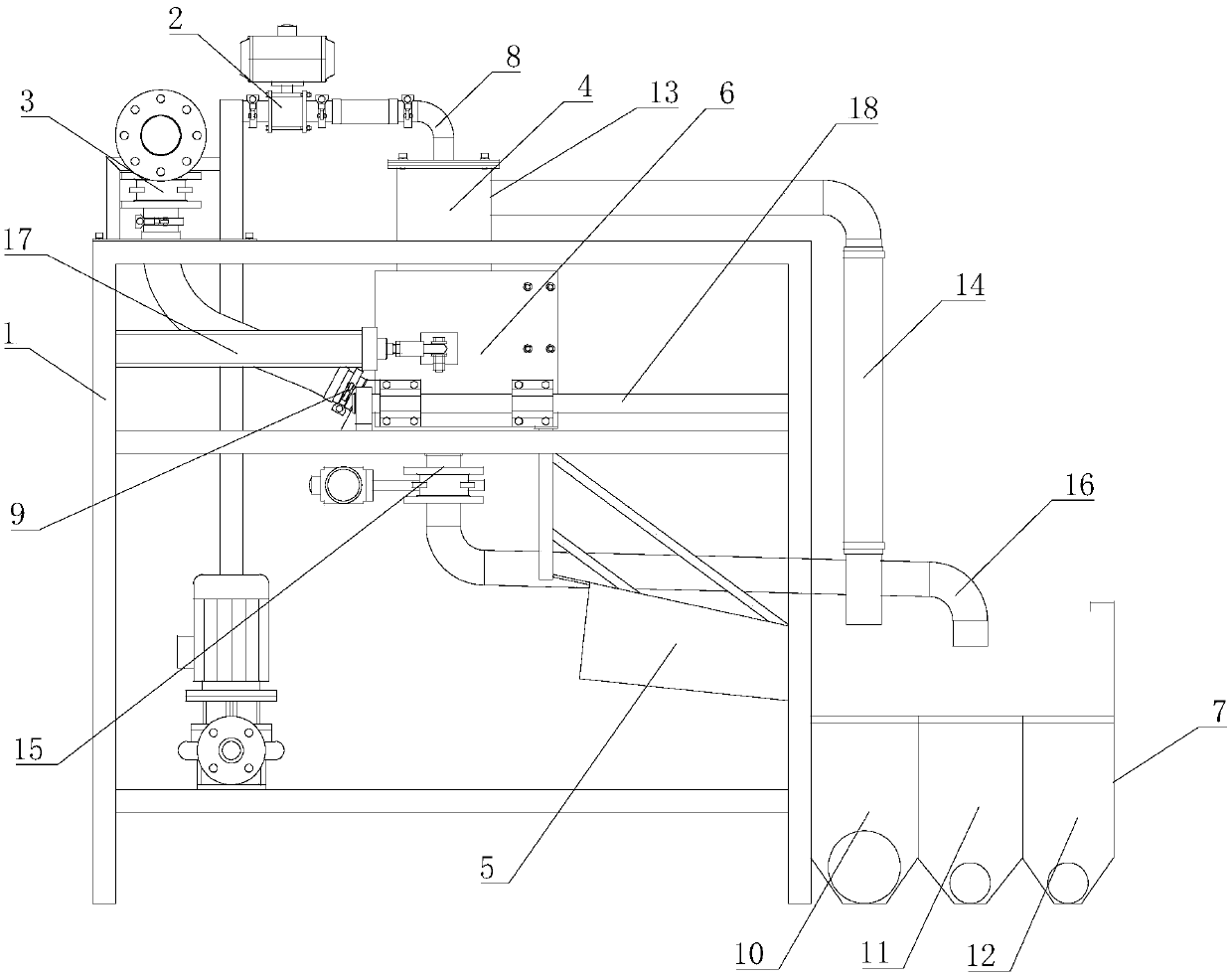

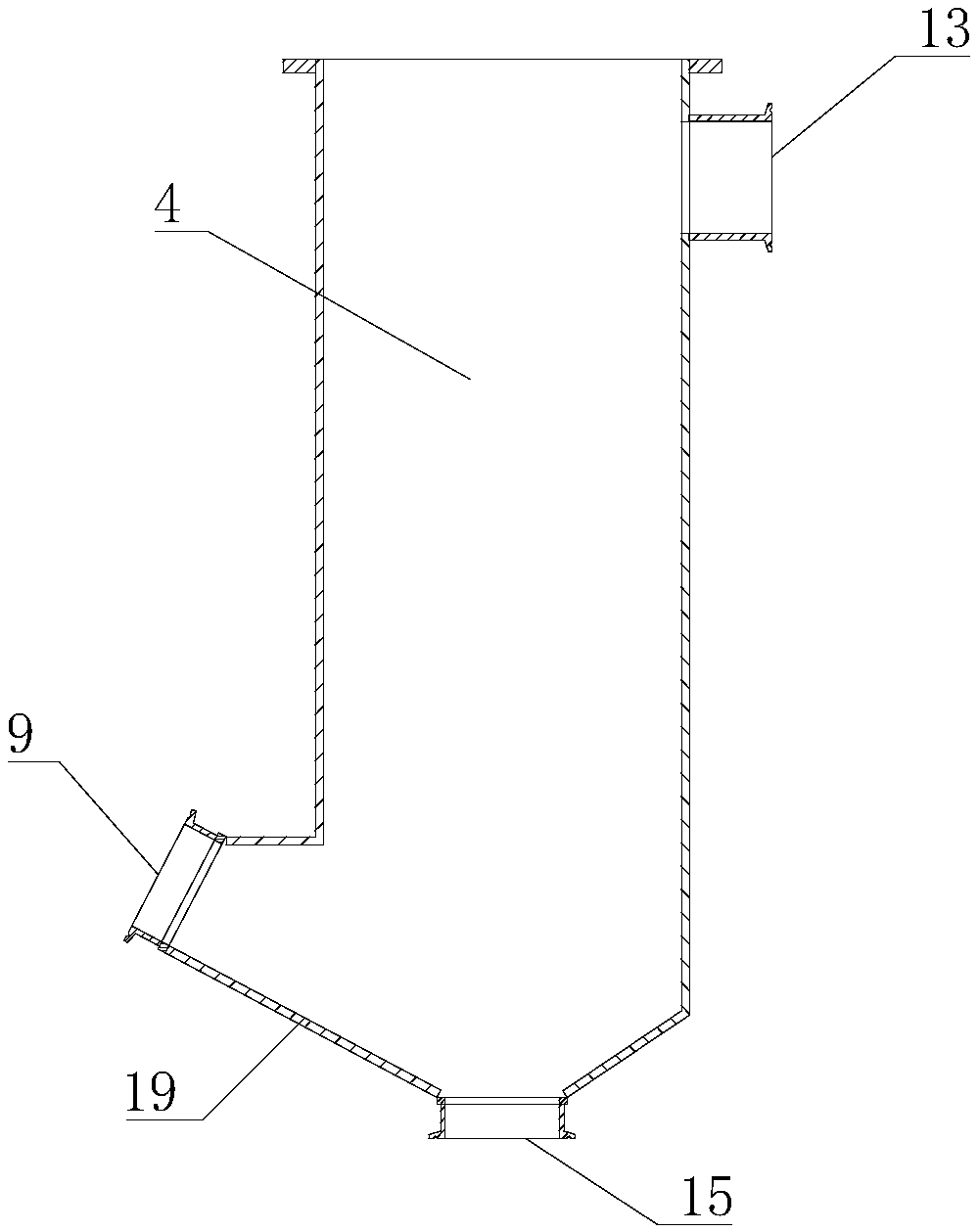

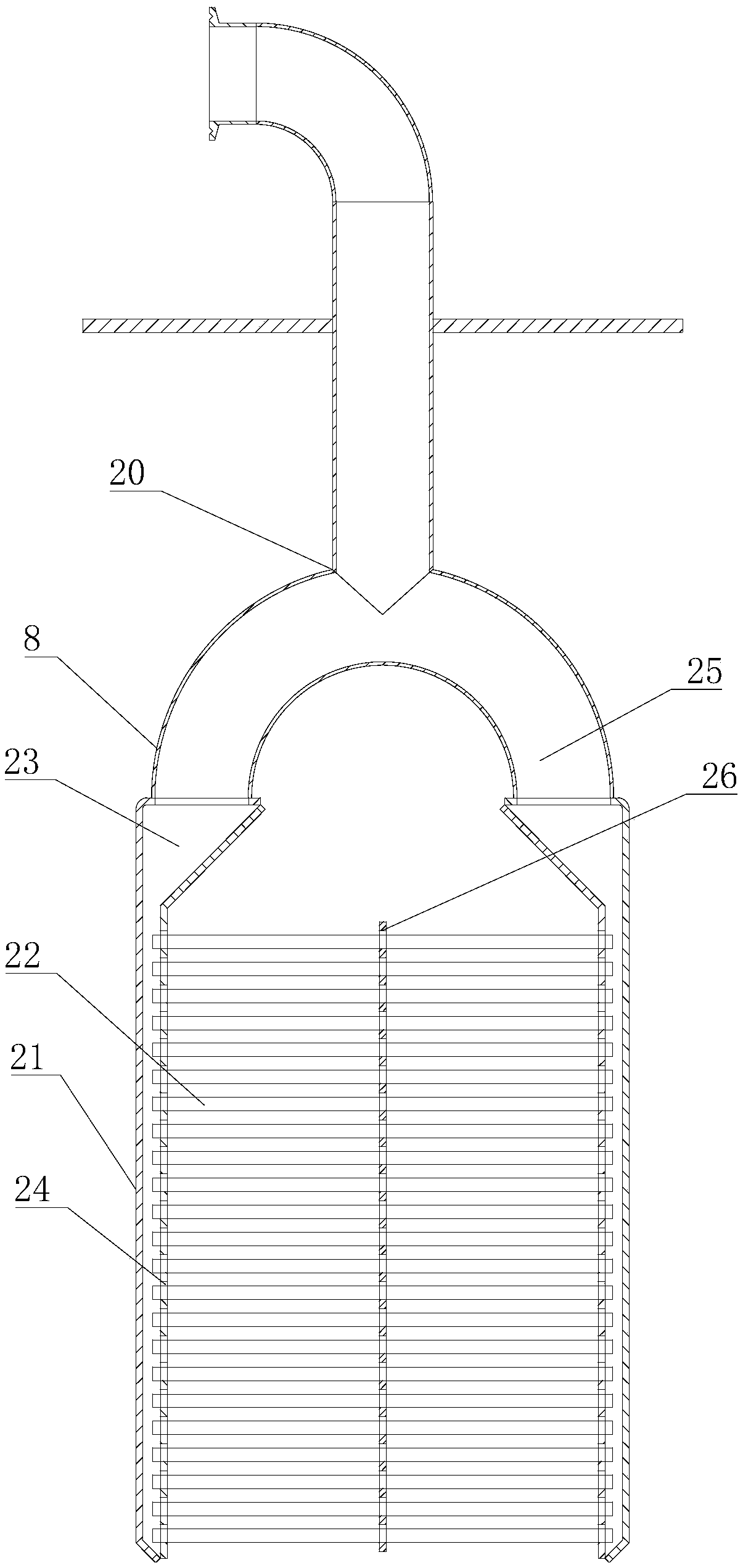

[0026] Such as figure 1 As shown, the fully automatic permanent magnet slurry iron remover includes a frame 1, a water inlet device 2, a slurry inlet device 3, a working chamber 4, a water outlet device 5, an iron removal device 6, and a slurry tank 7; the described work The cavity 4 is fixedly installed on the frame 1, and a medium cage 8 is arranged inside it; the water inlet device 2 is connected with the medium cage 8; the slurry feeding device 3 is connected with the working cavity 4 The slurry inlet 9 on the top is connected; the slurry tank 7 includes a slurry outlet tank 10, a slurry return tank 11, and an iron discharge tank 12; the iron removal device 6 can be installed on the frame 1 in a horizontal and linear reciprocating manner and Placed on the outside of the working chamber 4 to cooperate with the working chamber 4 to absorb iron filings in the slurry; the working chamber 4 is provided with a slurry outlet 13 to drain to the slurry outlet 10 through a slurry ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com