Method and device for eliminating metal braid burrs on cable shielding layer

A cable shielding layer and metal braiding technology, which is applied in metal processing equipment, cable/conductor manufacturing, circuits, etc., can solve the problems of limited wire installation, wire cannot be shipped, broken skin, etc., and achieves simple structure and convenient installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with example and accompanying drawing, the present invention will be further described:

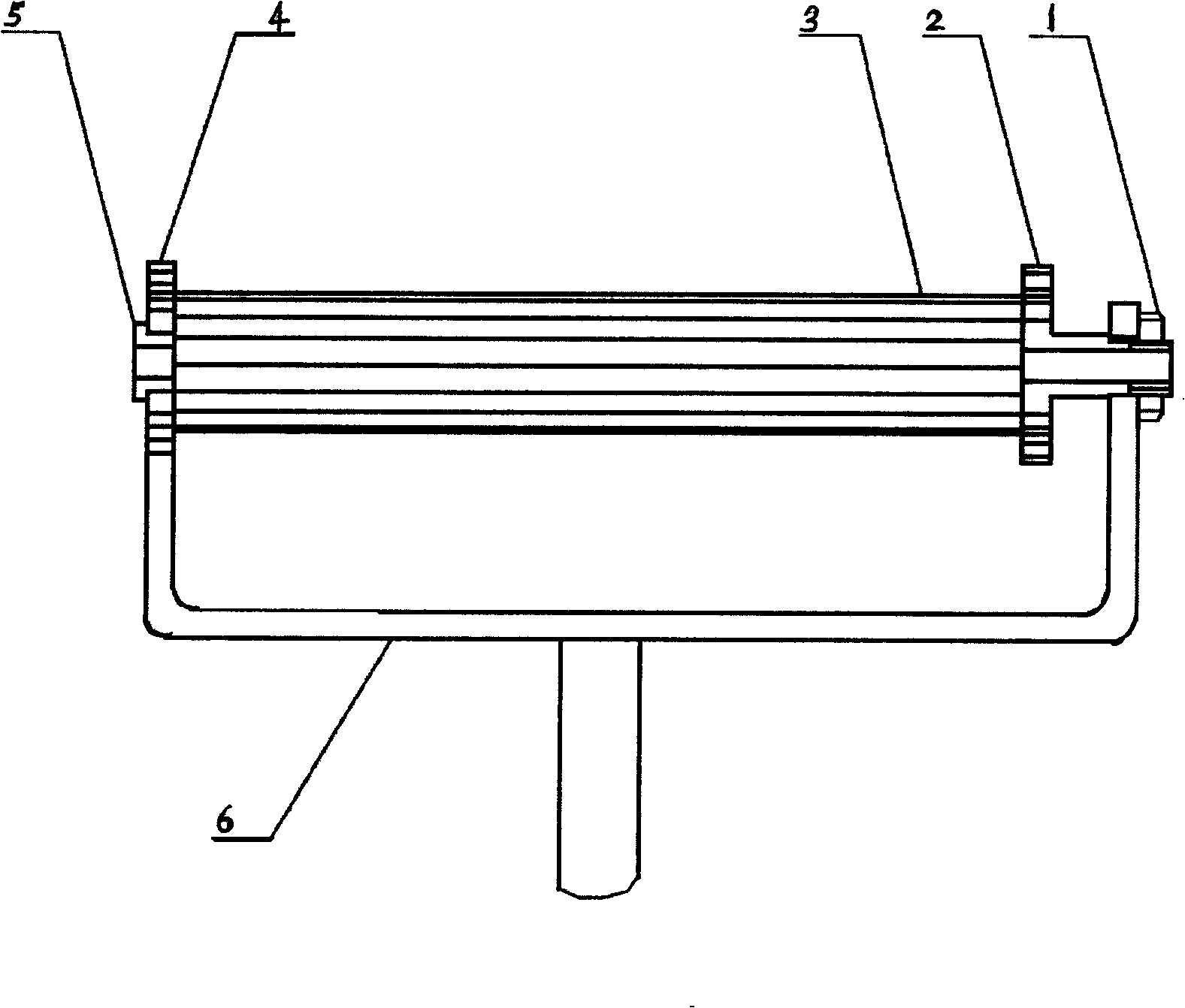

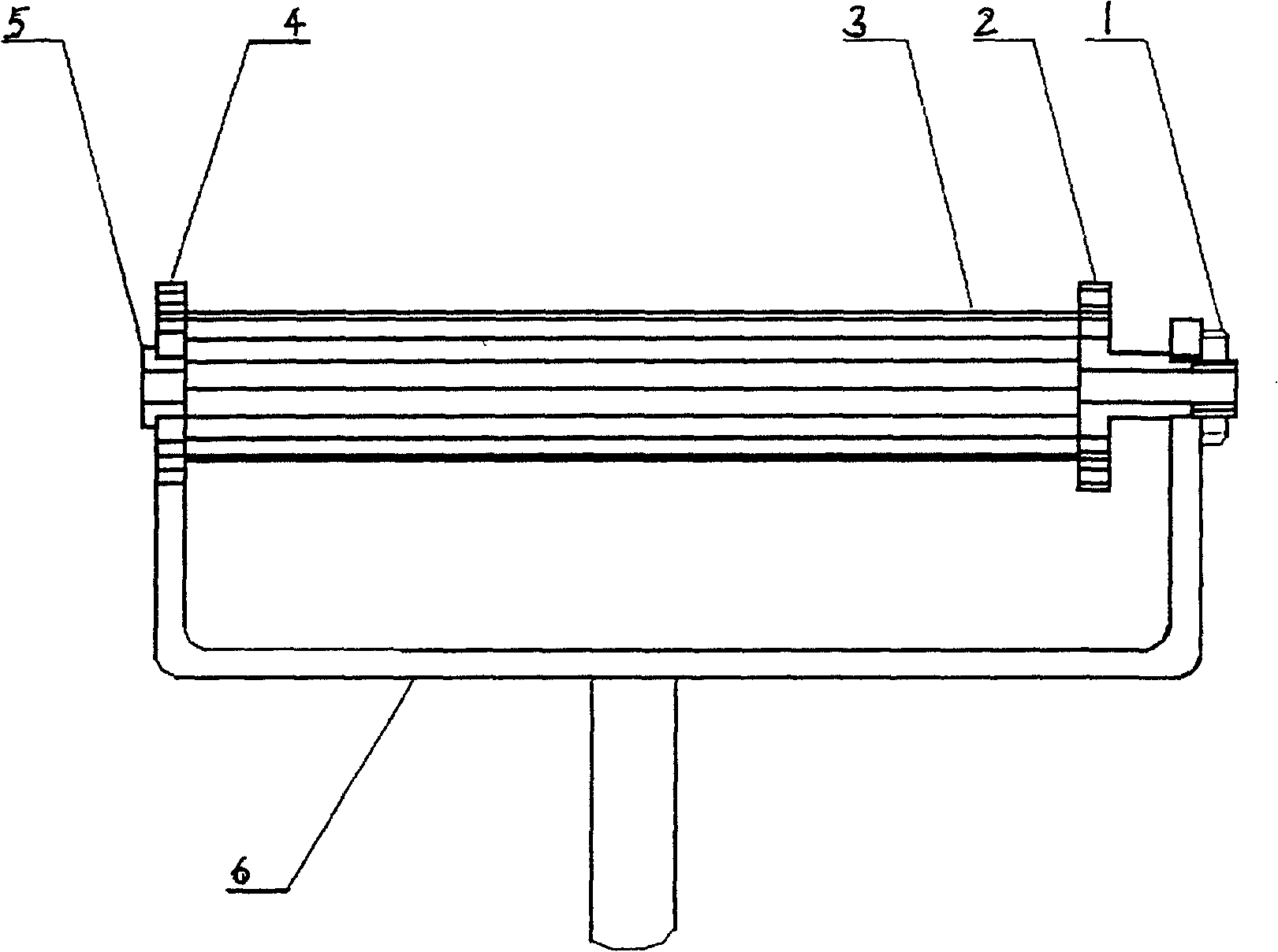

[0012] A specification for braided wire with an outer diameter of φ20mm or less and a general-purpose specific structure for removing the wire braiding burr of the cable shielding layer, including a fixed nut 1, a rear distribution plate 2, a solid PU strip 3, and a front distribution line Disc 4, wire passing mold 5 and support frame 6 are installed according to the structure provided in the accompanying drawings. The rear distribution disc 2 and the front distribution disc 4 are installed at the two ends of the support frame 6 made of sheet metal, and the support frame The distance between the two ends of 6 is 400mm. The diameter of the front distribution plate 4 is φ70mm. There are two layers of circular distribution holes on the disk. The first layer is 18 holes, and the second layer is 15 holes. The warp is φ5mm, the distribution diameter of the first laye...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap