Toilet seat paper setting method, apparatus therefor and toilet seat paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

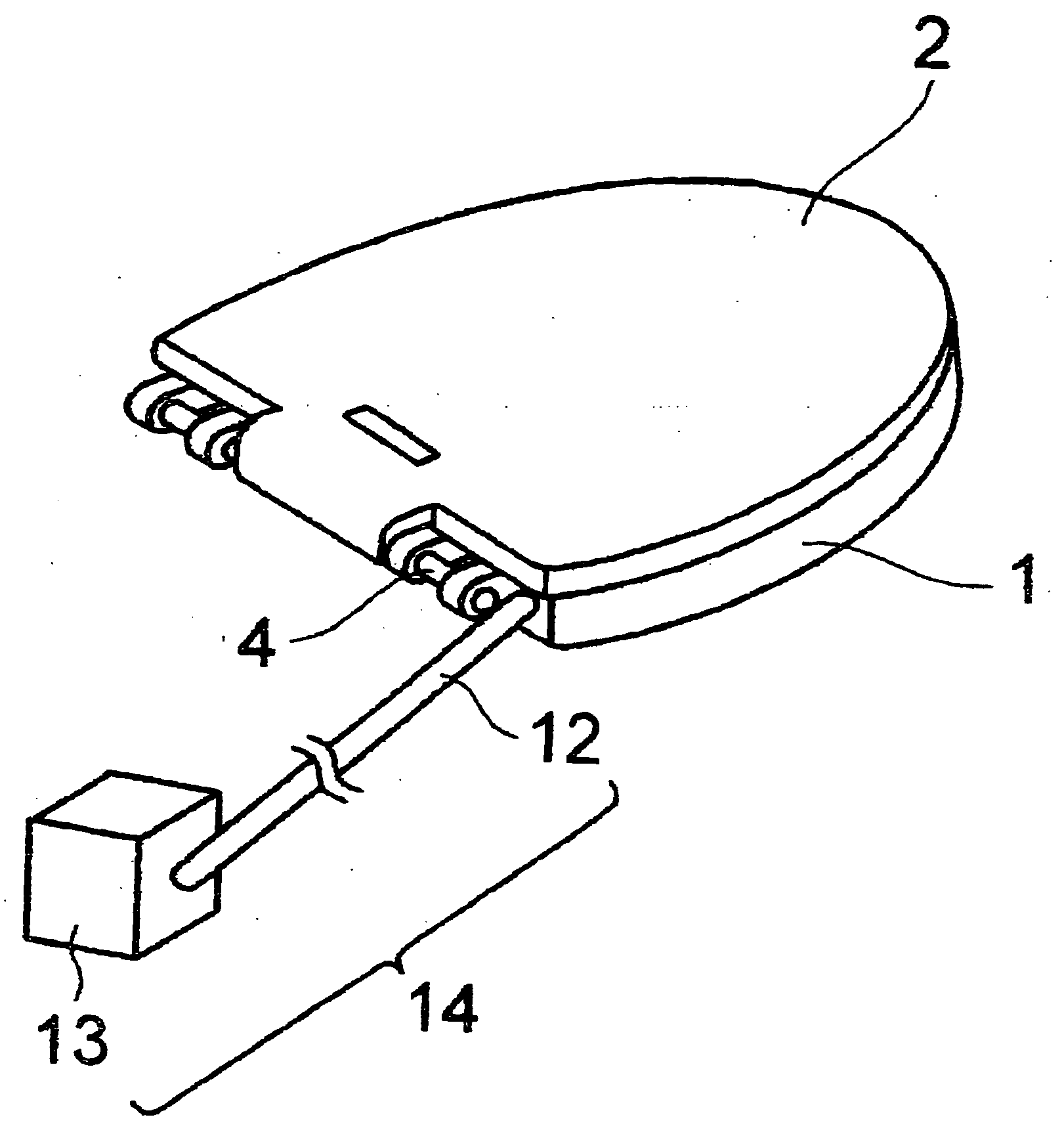

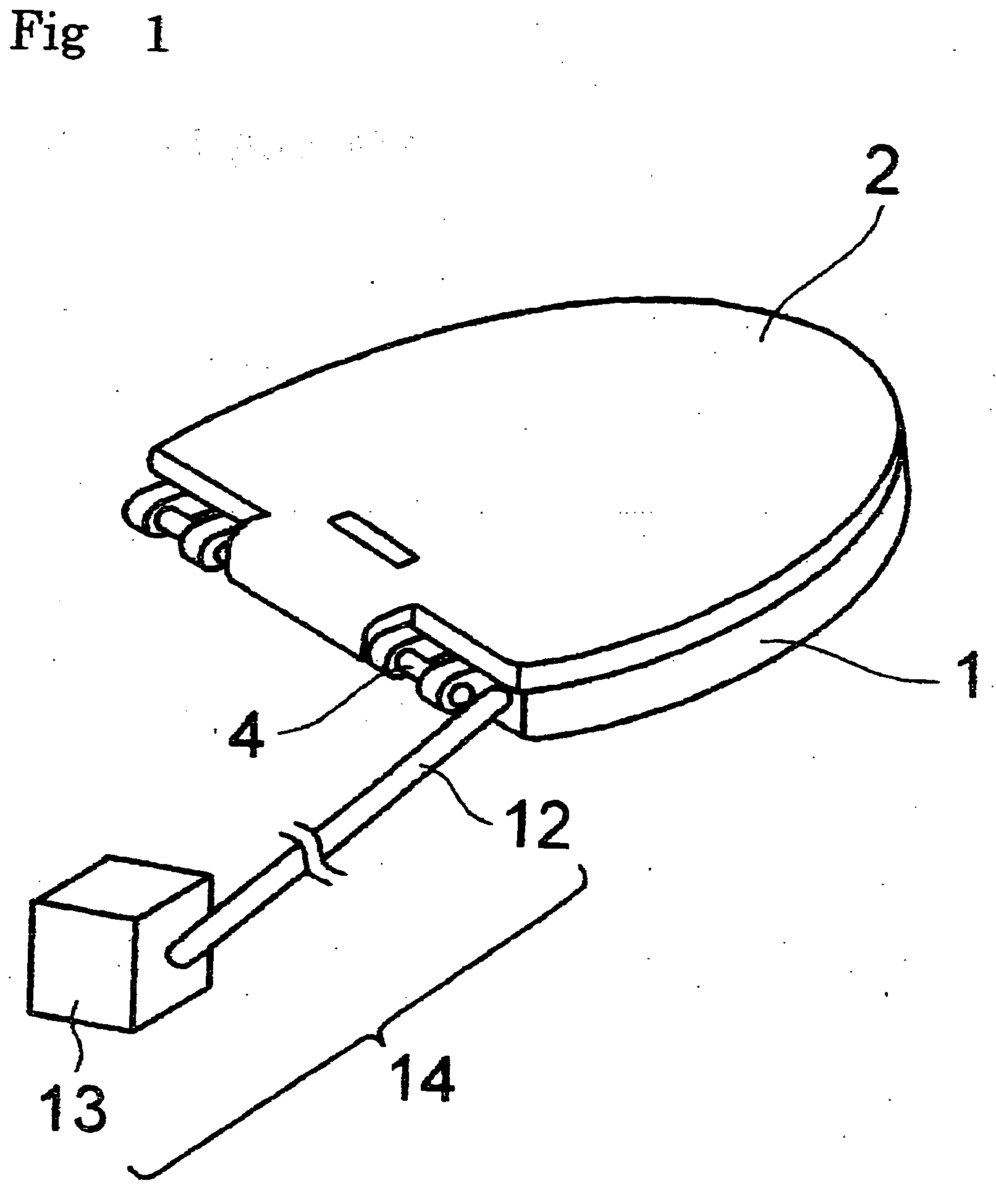

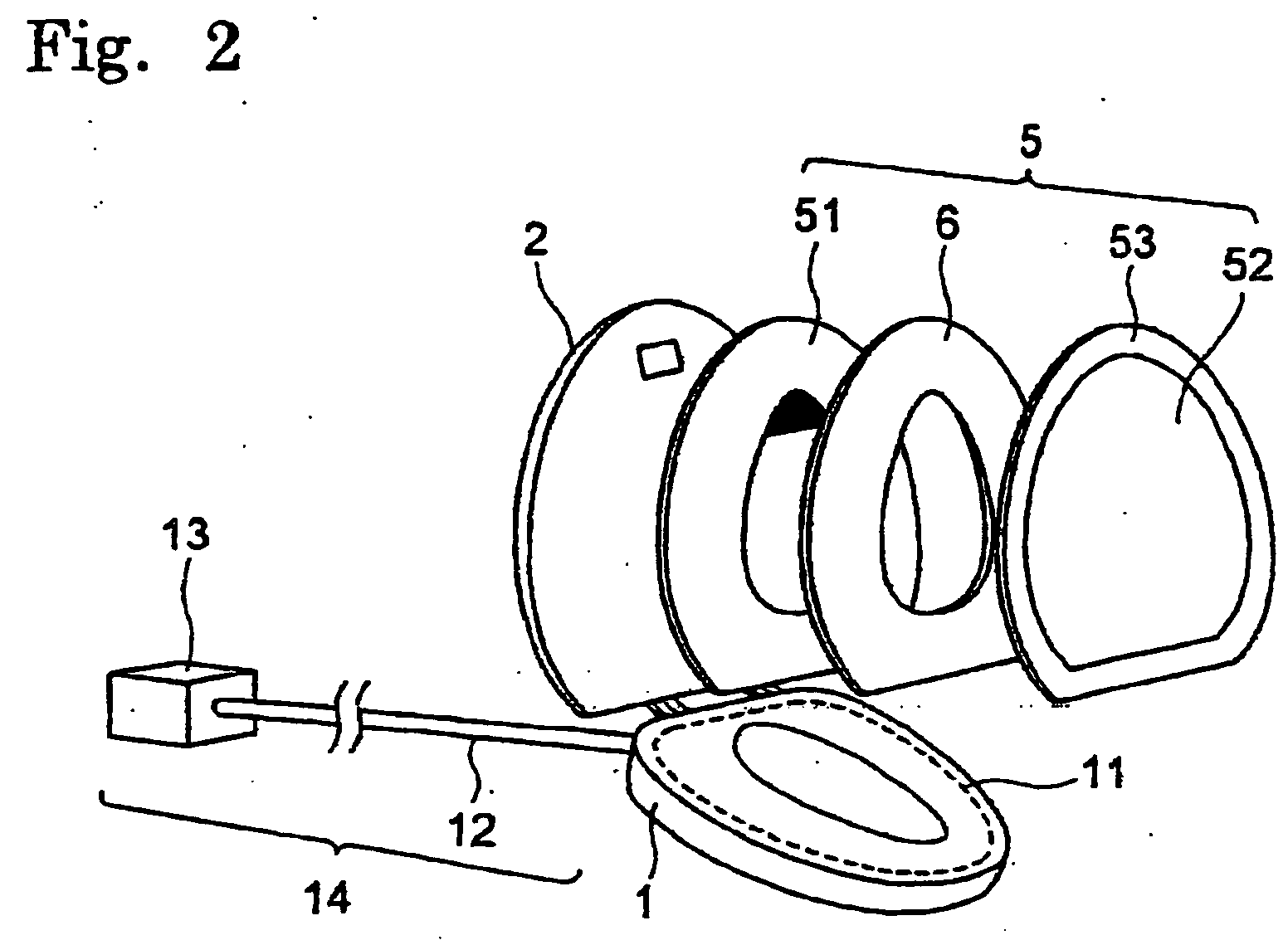

[0044] First, embodiment 1 will be described on the basis of FIGS. 1 to 4. FIG. 1 is a perspective view of an outer appearance of a toilet seat arranged assembled together with a toilet cover, FIG. 2 is an exploded perspective view of the toilet seat and a paper cassette contained within the toilet cover, FIG. 3 is a perspective view of an outer appearance of the toilet in the used state and FIG. 4 is a sectional view of the toilet seat.

[0045] In FIGS. 1 to 3, reference numeral 1 is a toilet seat, 2 is a toilet cover and 3 is a toilet bowl main body. The toilet seat 1 is freely rotatably attached to the toilet cover 2 through a pivot shaft 4 and assembled into one unit, and a paper cassette 5 is detachably provided at the back side of the toilet cover 2.

[0046] The paper cassette 5 comprises comprises a container portion 51 containing a stack of sheets of toilet seat papers 6 which are stacked in layers so that the sheet papers 6 formed in a ring-shape, for example, capable of cove...

embodiment 2

[0055] In the above-described Embodiment 2, the description has been made as to an example in which the toilet seat 1 is of the single piece structure, the description of the embodiment 2 will now been made in terms of the toilet seat 1 that has a double layer structure including an upper layer 101 and a lower layer 103 on the basis of FIGS. 5 to 7. FIG. 5 is a perspective view showing an outer appearance of the toilet seat assembled together with the toilet cover, FIG. 6 is an exploded perspective view of the toilet cover and the paper cassette contained within the toilet cover, and FIG. 7 is a perspective view of the toilet bowl in the state ready for use, the same reference numerals used in FIGS. 1 to 4 of the embodiment 1 designate the same or identical components.

[0056] The toilet seat 1 is arranged in the double layer structure including the upper and the lower layers in order to make sure that, since the lower layer toilet seat 102 which corresponds to the toilet seat 1 of a...

embodiment 3

[0058] In embodiment 3, a toilet seat paper 60 which is an improvement of the toilet seat paper 6 of embodiments 1 and 2 will now be described on the basis of FIG. 8. FIG. 8 is a plan view.

[0059] In FIG. 8, the reference numeral 60 is the toilet seat paper placed on the seat surface of the toilet seat to cover it, and it is shaped into an annular shape which follows an eclipse having a major axis extending in the horizontal direction in FIG. 8. The right hand direction of the major axis is the front direction of the user and the left hand direction of the major axis is the back side of the user.

[0060] The reference numeral 62 is a projection portion formed to extend outwardly at a portion of an outer periphery of the toilet seat paper 60 and is projected to have an surface area that can be at lease picked by finger tips. Although the illustrated projection portion 2 is formed to have a substantially U-shaped outer periphery; another suitable configuration, such as square or triang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shape | aaaaa | aaaaa |

| Water solubility | aaaaa | aaaaa |

| Thermal insulator | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap