Manufacturing method of combined type middle sole

A manufacturing method and combined technology, applied in footwear, applications, household appliances, etc., can solve problems such as insufficient comfort and insufficient softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

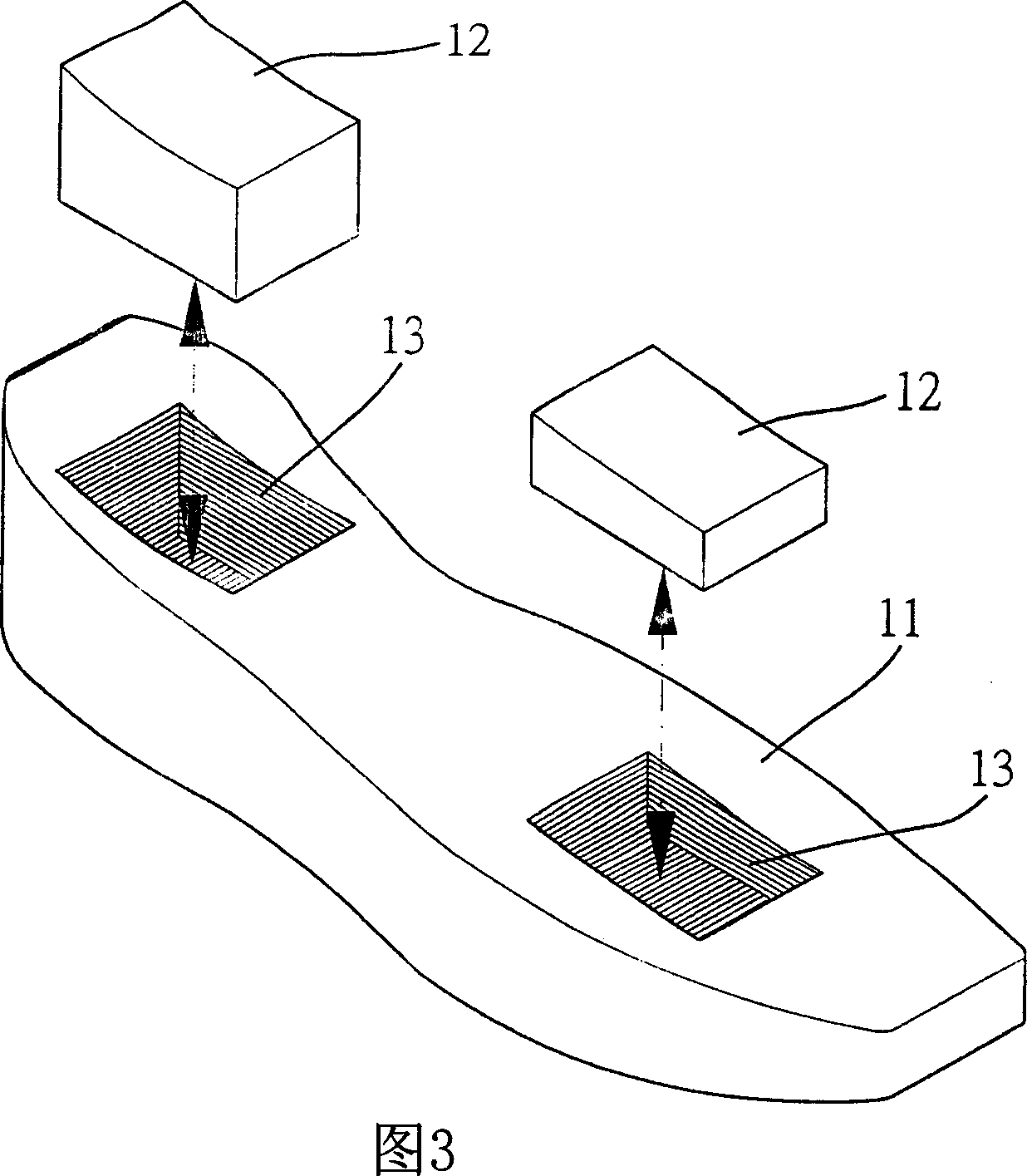

[0019] The invention provides a method for manufacturing a combined midsole of shoes, especially using PU glue as an interface adhesive in a rough structure, so that EVA material and PU material are aggregated together, thereby producing an elastic, soft and light midsole. The method of the midsole of the shoe with unique characteristics, and can strengthen the elastic characteristic or lightness characteristic of the midsole of the shoe according to different manufacturing methods.

[0020] In order to enable a more in-depth and specific understanding of the manufacturing method of the present invention, the technical means, structural implementation and effects of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

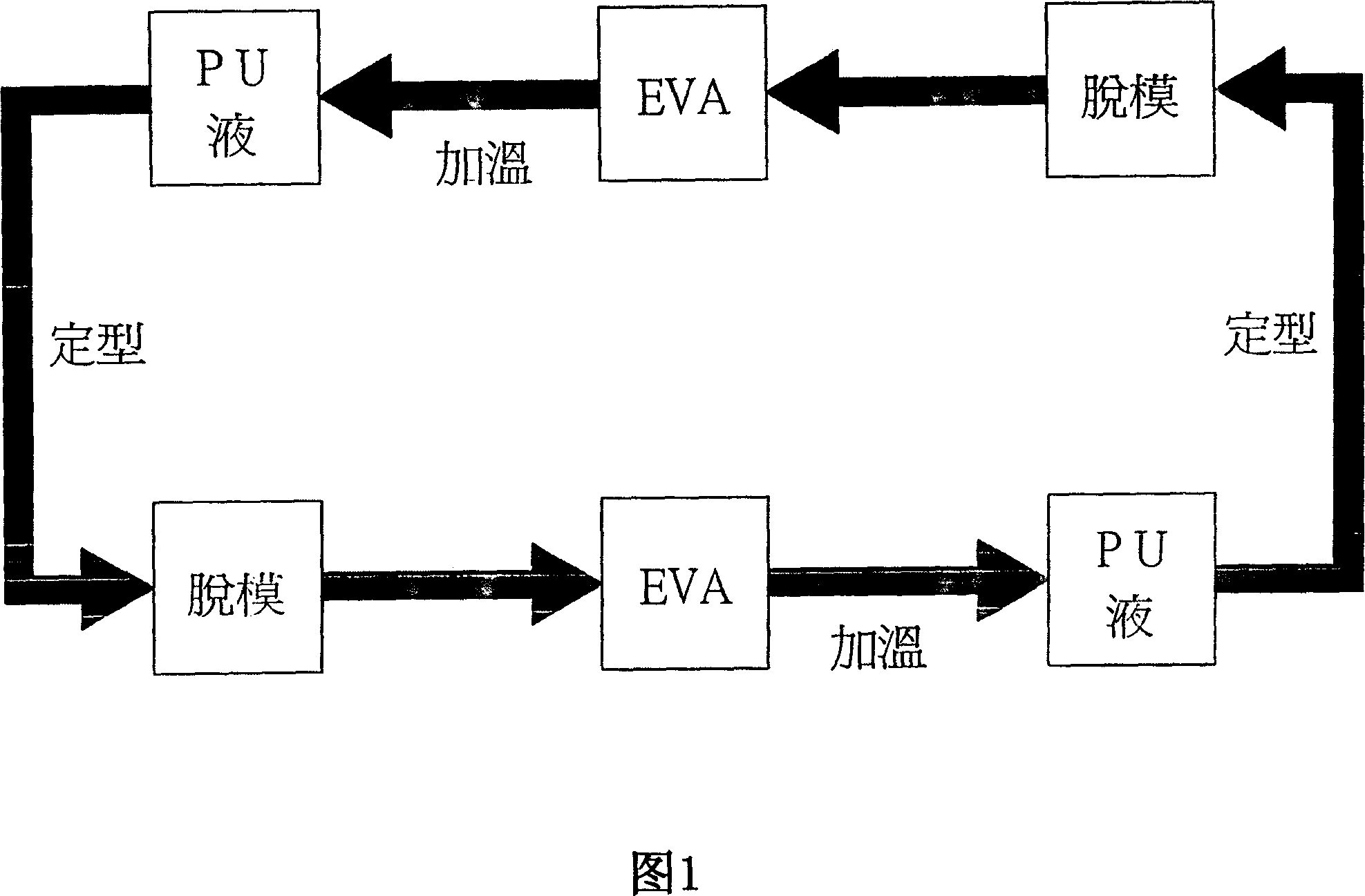

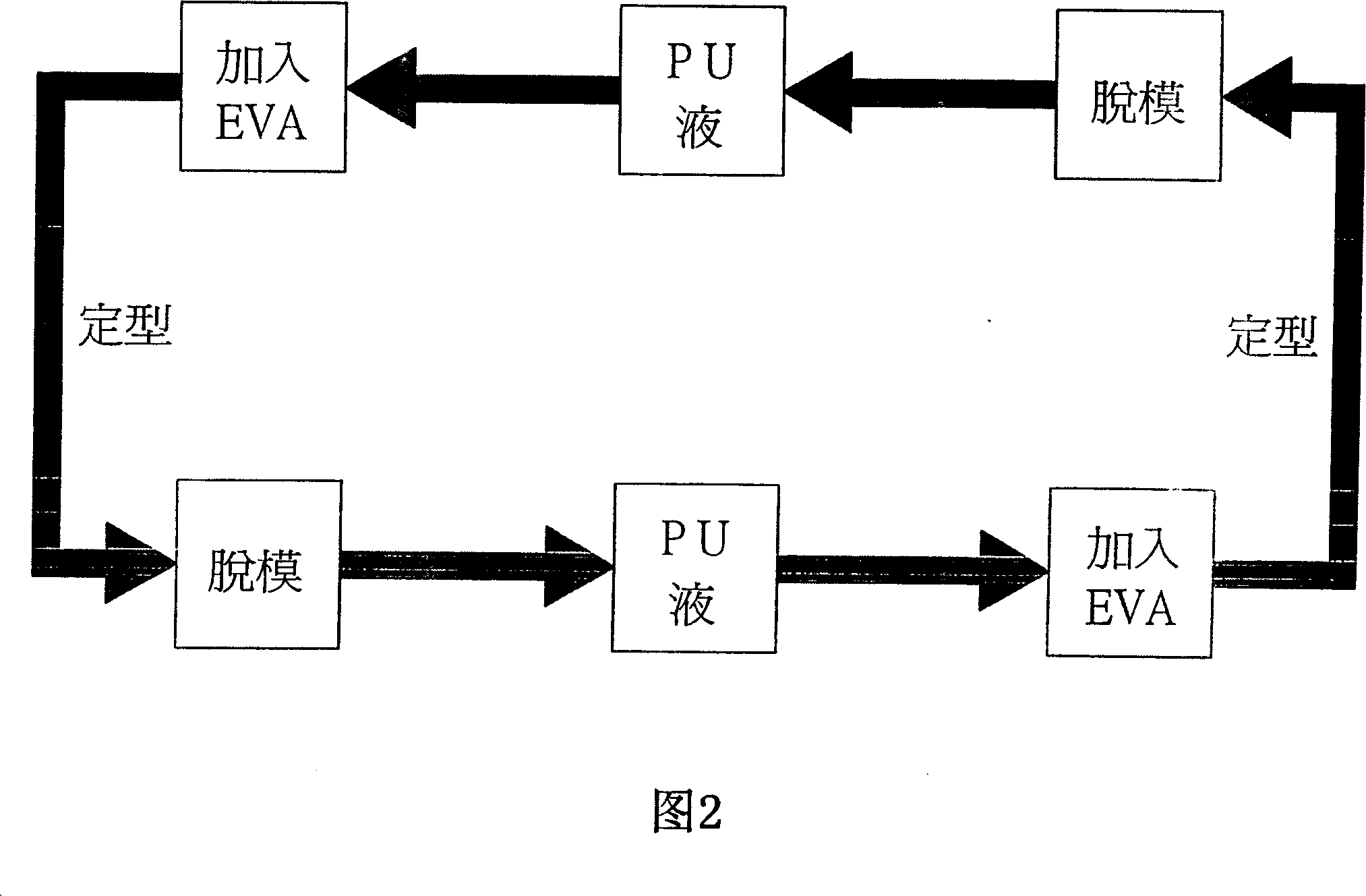

[0021] First, as shown in Fig. 1, Fig. 3 and Fig. 4, the manufacturing method of the combined midsole of the present invention mainly includes: placing a prefabricated EVA material 11 in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com