Oxygen-rich type synergism fuel economizer

A technology of fuel economizer and oxygen-enriched generator, which is applied to machines/engines, adding non-fuel substances to fuel, internal combustion piston engines, etc., which can solve the problems of incomplete combustion of fuel, low oxygen utilization rate, and large energy consumption and other issues, to achieve the effect of improving fuel utilization efficiency, increasing fuel utilization, and promoting full response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

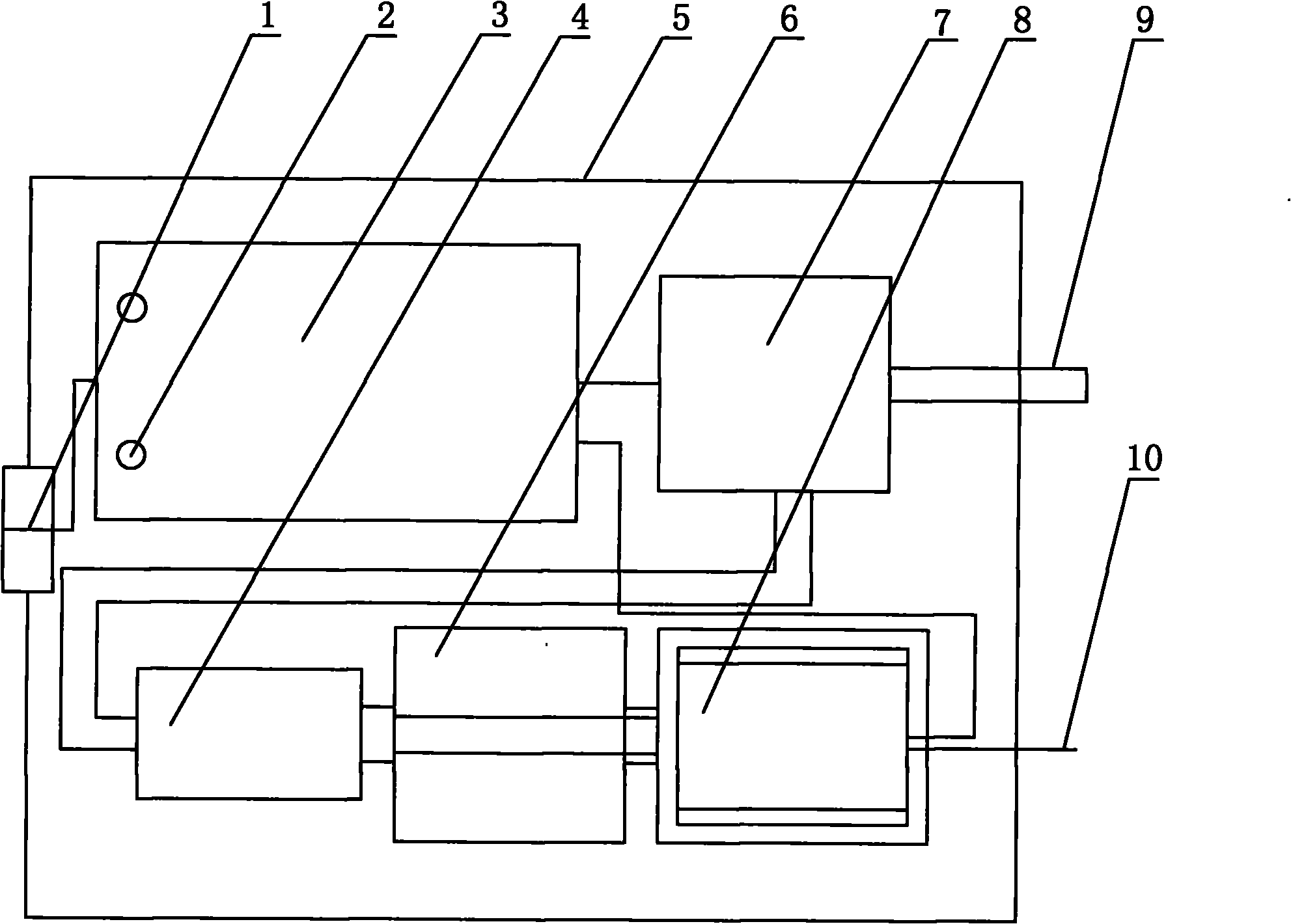

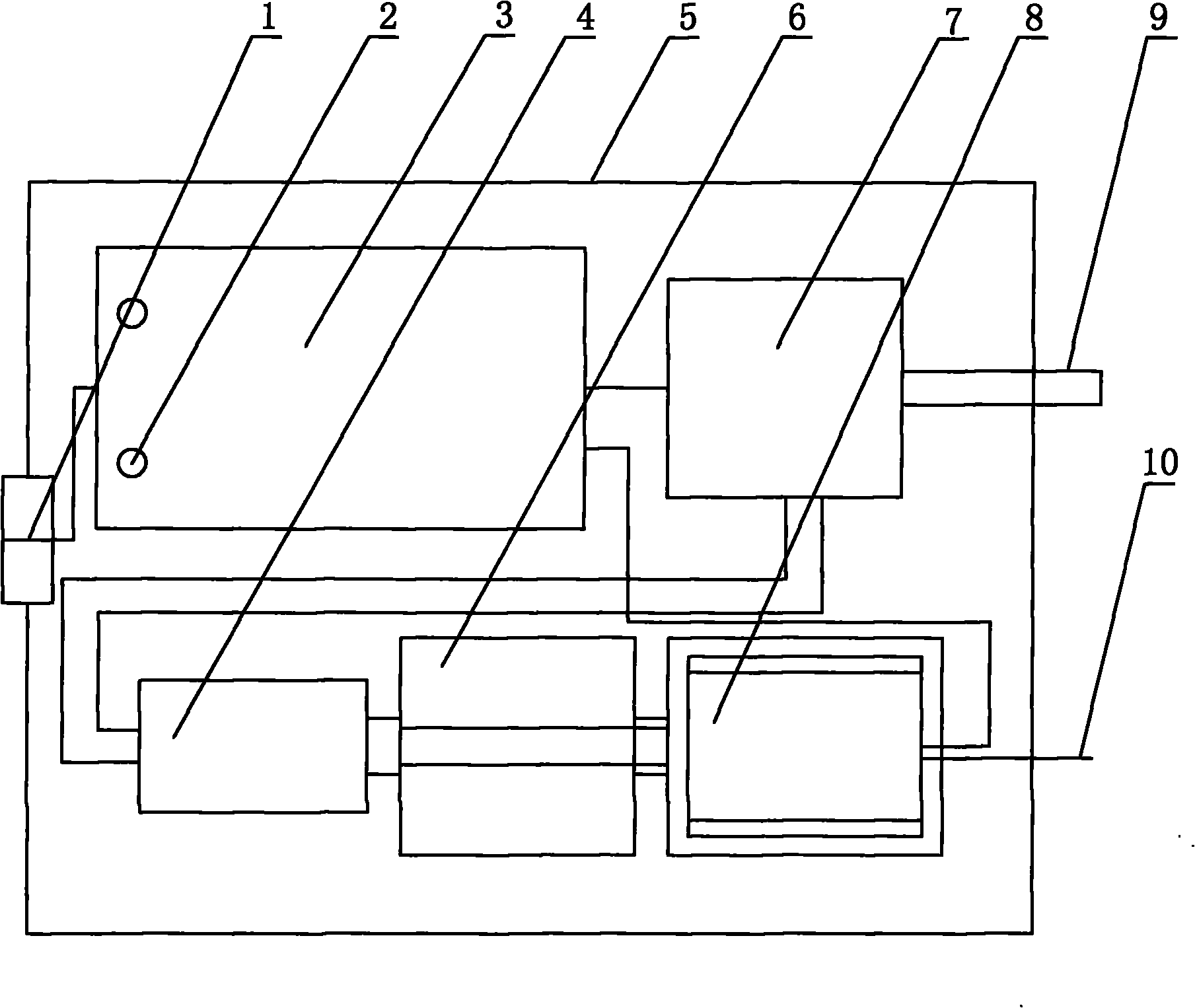

[0011] Example: such as figure 1 As shown, the oxygen-enriched fuel-saving device mainly includes: housing (5), power switch (1), transformer (8), circuit board (3), air pump (7), oxygen-enriched generator (4) And trachea (9), described circuit board (3), air pump (7), motor (6) and oxygen-enriched generator (4) are all fixed in casing () 5 insides; Characteristic is in motor (6) A transformer (8) is added in the front, and its effect is to change high-voltage electricity into low-voltage electricity. The motor (6) is arranged on the left side of the transformer (8) at the same horizontal position, and is connected with the transformer (8) by wires. The left side of the transformer (8) is provided with an oxygen-enriched generator (4), and the oxygen-enriched generator (4) is connected with the air inlet of the air pump (7) through a gas pipe (9), and the air pump (7) is located at the end of the transformer (8). Above, the air pump (7) is connected with a trachea (9), and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com