Process for manufacturing a light alloy wheel rim and wheel rim resulting therefrom

A light alloy and rim technology, applied in the manufacture of tools, wheels, rims, etc., can solve problems such as limited efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

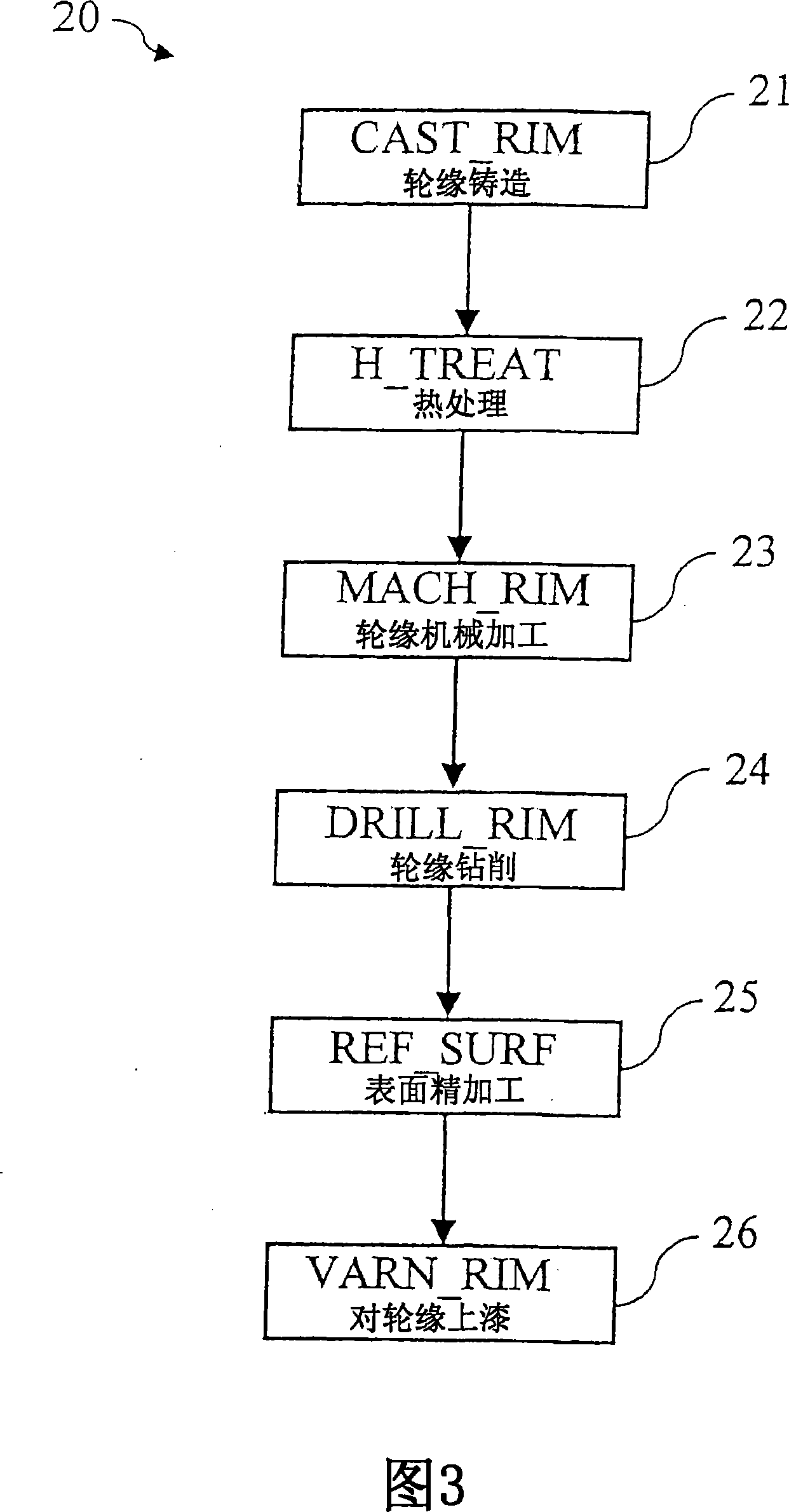

Method used

Image

Examples

Embodiment Construction

[0022] In the drawings, the same or similar elements are denoted by the same reference numerals.

[0023] The term rim axis of rotation refers to the axis about which the rim will rotate in use.

[0024] The term radial direction refers to a direction substantially perpendicular to the axis of rotation of the rim.

[0025] The term axial direction refers to a direction substantially parallel to the axis of rotation of the rim.

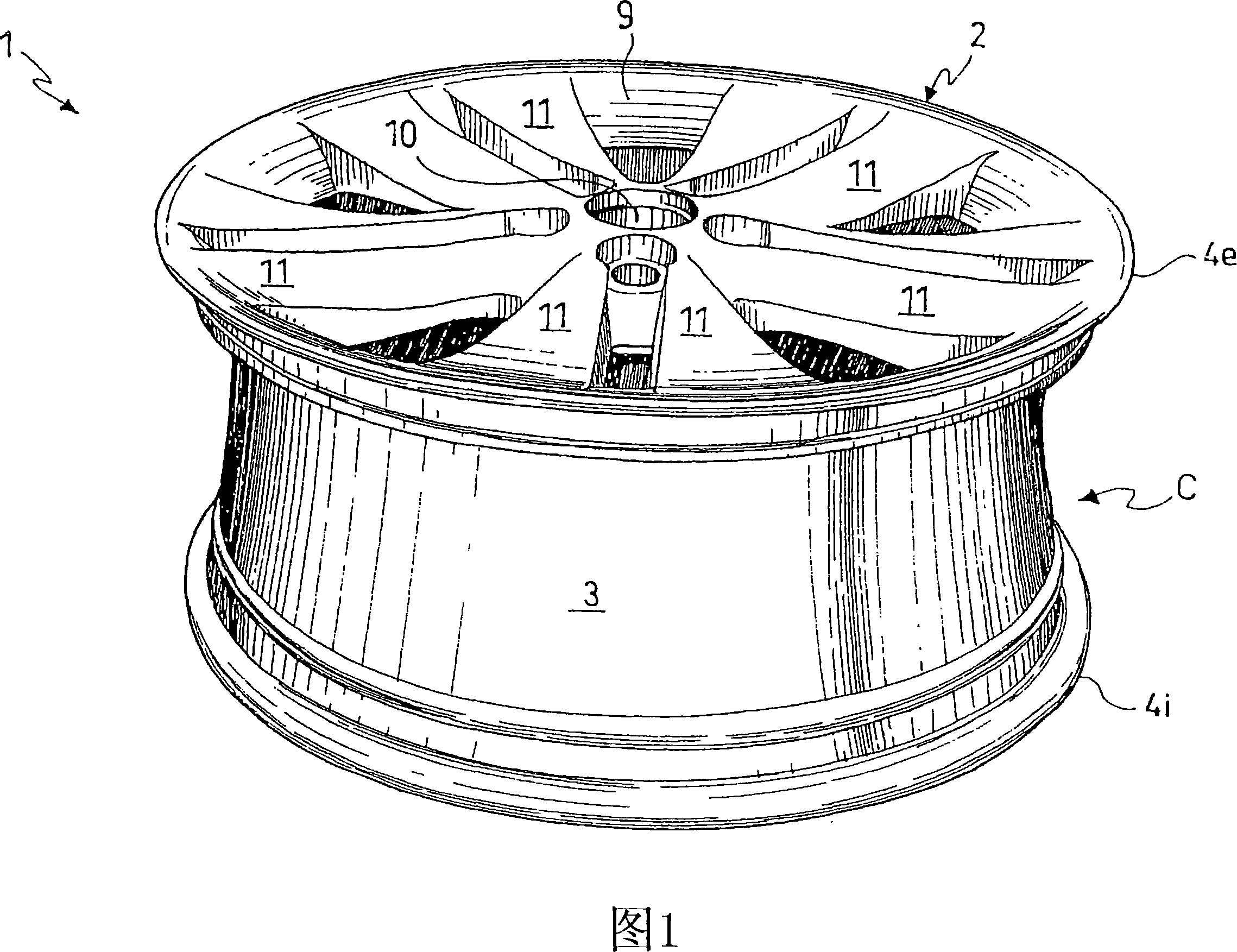

[0026] With particular reference to Figure 1 , a light alloy rim 1 (for example of aluminium) is illustrated of the type that can be used, for example, in automobile wheels.

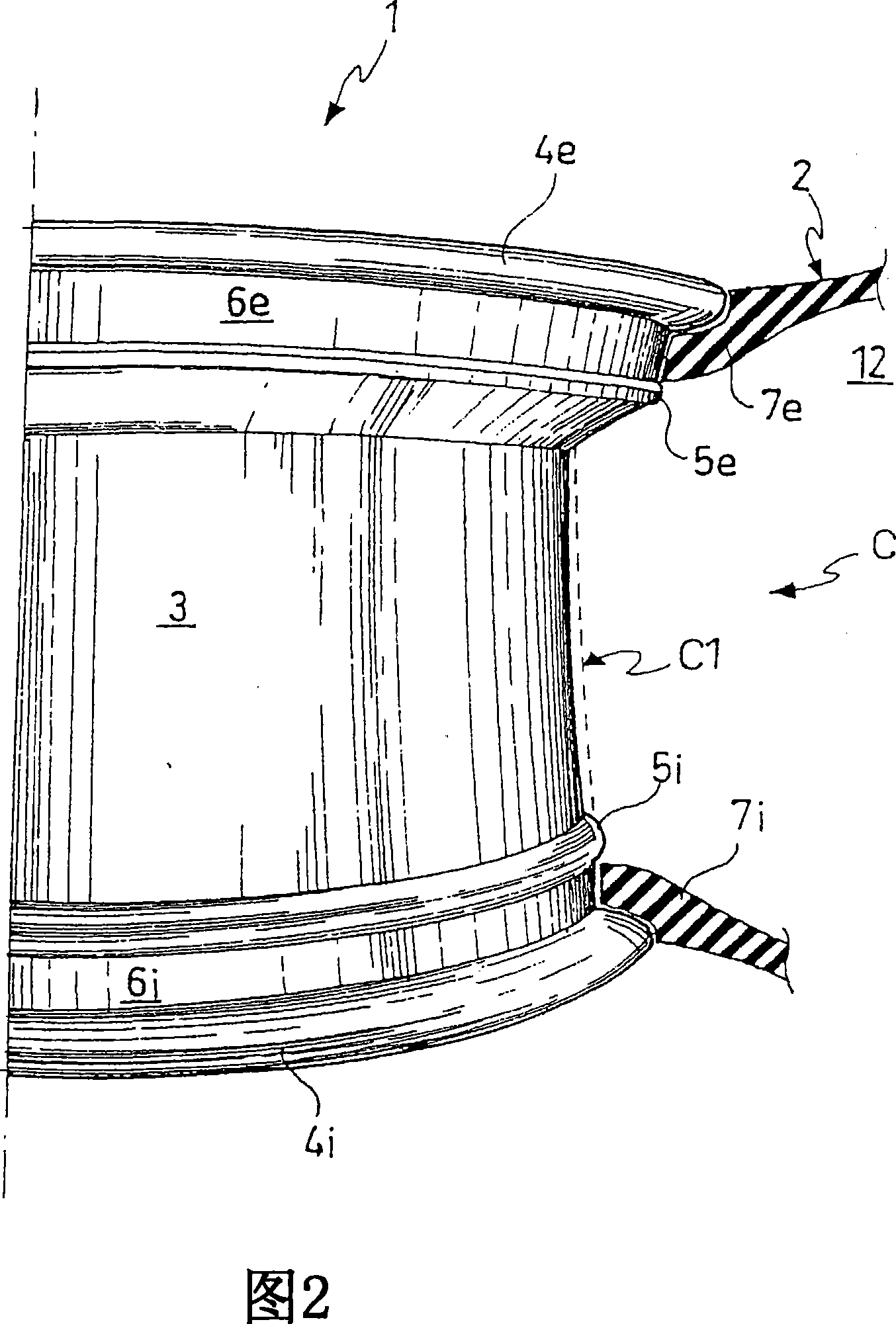

[0027] The rim comprises a disc 2 and an annular part or ring 3 . The latter comprises a first rim 4i or inner rim and a second rim 4e or outer rim, each extending substantially in a radial direction along the respective circumference of the ring 3 . The rims 4i and 4e are arranged at two axially opposite sides of the ring 3 and are respectively arranged in inner and outer pos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com