Restraint system for a driver of a vehicle

a technology for a driver, which is applied in the directions of vehicle safety arrangements, pedestrian/occupant safety arrangements, transportation and packaging, etc., can solve the problems of limiting the freedom of movement of the driver, and affecting the safety of passengers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

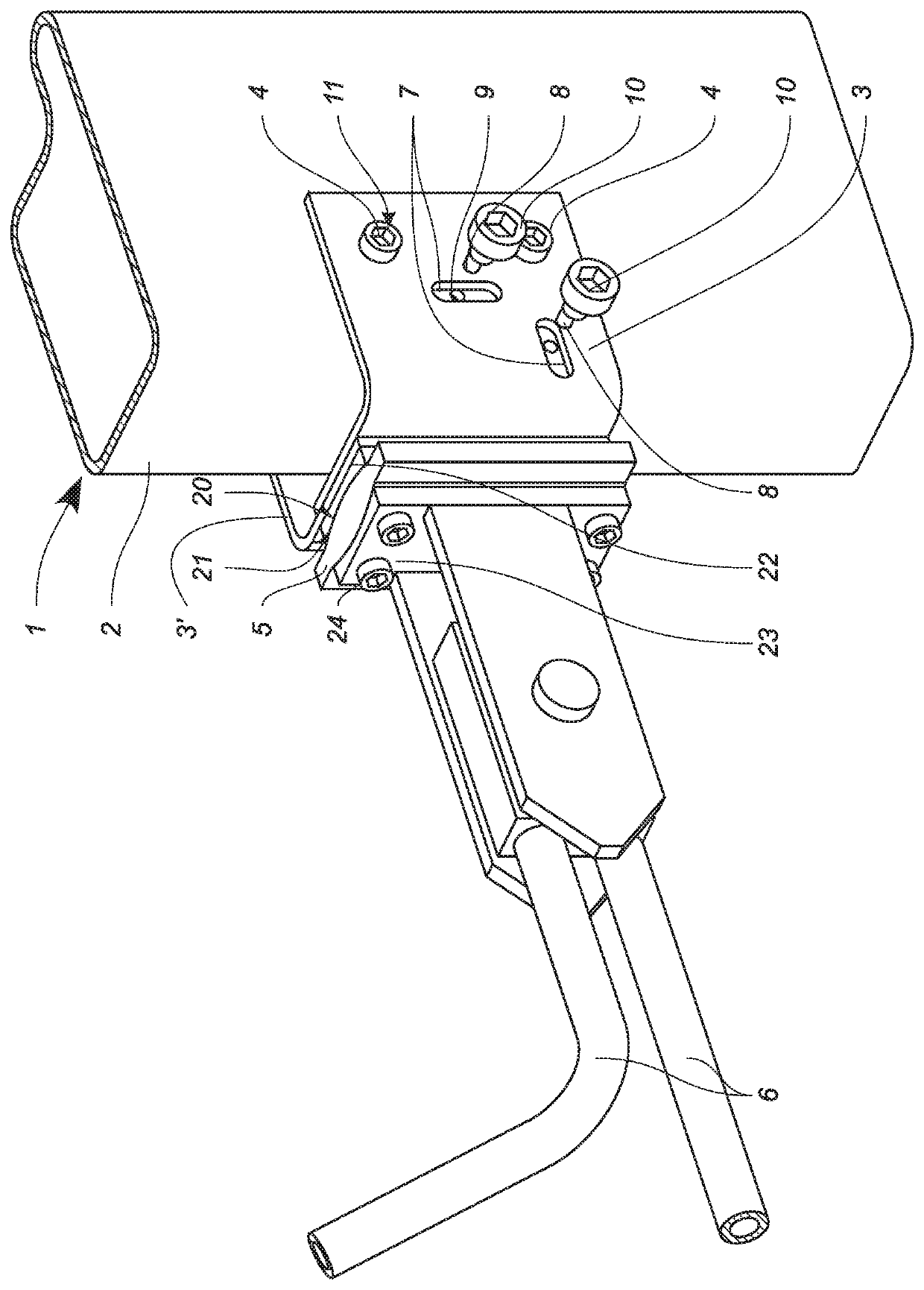

[0016]The only FIGURE shows a three-dimensional view of a detail of an industrial truck 1, substantially only one pillar 2 thereof being visible. Two brackets 3, 3′ are secured to this pillar 2 by means of screws 4. As an alternative to the screws 4, the bracket 3 may also be configured as a clamp so as to avoid in this manner drilling into the pillar 2. This may be significant, in particular, in the case of pillars 2 which are configured to be thin. A support 5 which bears a pivotable protective bar 6 is supported on the bracket 3.

[0017]Moreover, a slot 7 is provided in the bracket 3, an eccentric 8 engaging in said slot. This eccentric 8 is supported on a threaded bore 9 of the pillar 2. By rotating the eccentric 8 an eccentric head 10 produces a rotational movement which is transmitted to the slot 7. The vertical component of this rotational movement is eliminated in this case by the slot 7 and only the horizontal movement component is transmitted to the bracket 3. In this manner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com