Pump including a moving member provided with a central duct and a diaphragm having engagement means bearing against said central duct, and a receptacle fitted therewith

a technology of diaphragm and moving member, which is applied in the direction of piston pumps, positive displacement liquid engines, instruments, etc., can solve the problems of pushbutton jamming and known pump not providing full satisfaction, so as to reduce mechanical stress, facilitate diaphragm operation, and reduce mechanical stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

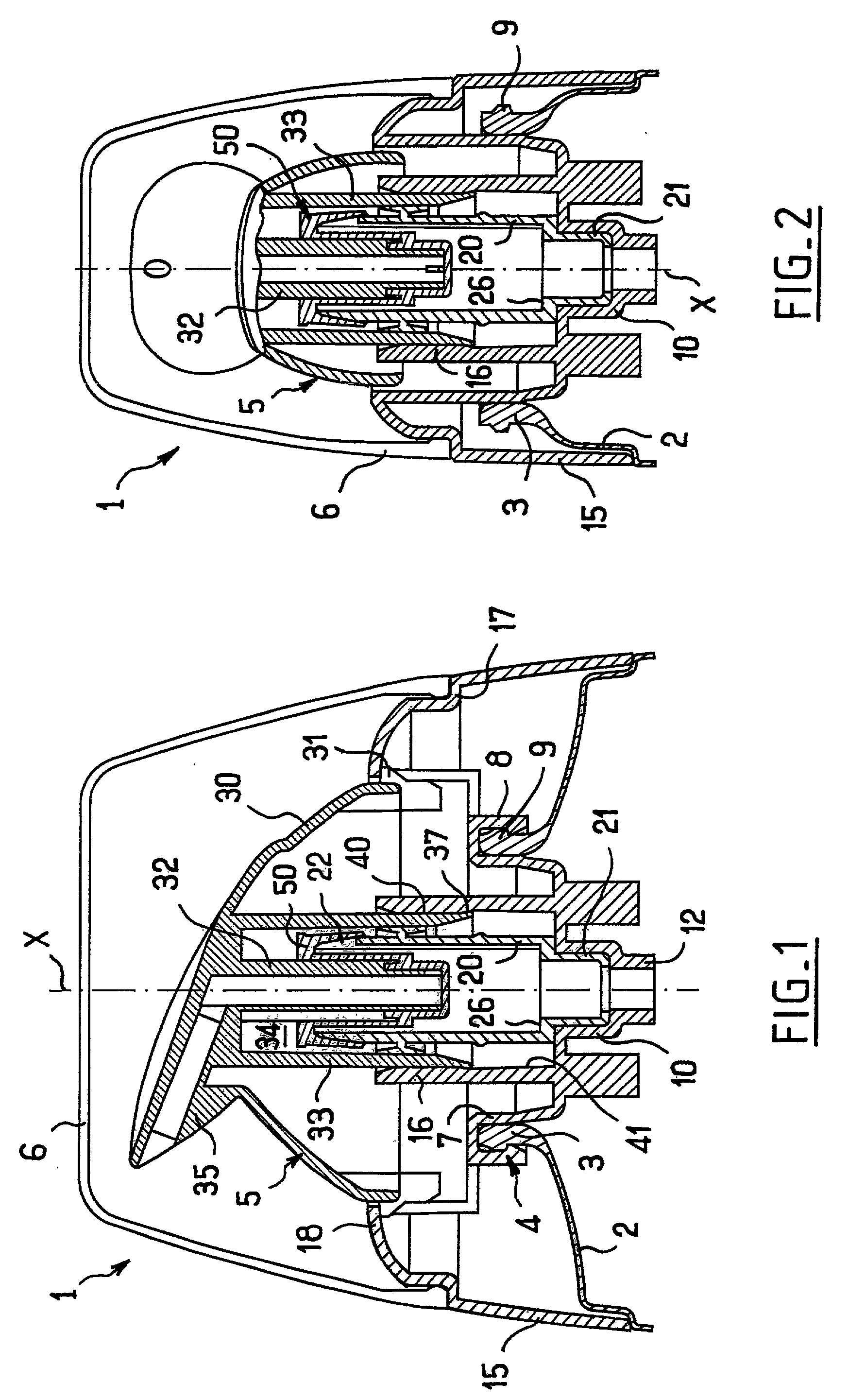

[0052] FIG. 1 shows a receptacle 1 having a tank-forming body 2, and the drawing shows only the top end thereof which defines a neck 3 onto which a support 4 is snap-fastened.

[0053] The support 4 constitutes a guide for mounting a pushbutton 5 to slide along an axis X, and it also serves to mount a removable closure cap 6 that covers the pushbutton 5 before first use thereof.

[0054] In the embodiment described, the support 4 has a sealing skirt 7 bearing in leakproof manner against the inside surface of the neck 3.

[0055] The sealing skirt 7 is extended radially firstly outwards by fixing tabs 8 that are snap-fastened on an annular rim 9 of the neck 3, and secondly inwards by a stepped wall 10 defining an endpiece 12 for connection to a dip tube (not shown).

[0056] An outer skirt 15 and a guide skirt 16 are made as a one-piece molding of plastics material together with the sealing skirt 7, the fixing tabs 8, and the stepped wall 10.

[0057] The outer skirt 15 extends around the neck 3 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com