Engine compartment structure of a work machine

a technology for work machines and engine compartments, applied in the direction of machines/engines, snow cleaning, tractors, etc., can solve the problems of difficult to improve cooling efficiency, high temperature inside the engine compartment, complex inside the engine compartment structure,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Preferred embodiment in accordance with the present invention will be described in detail with reference to the accompanying drawings.

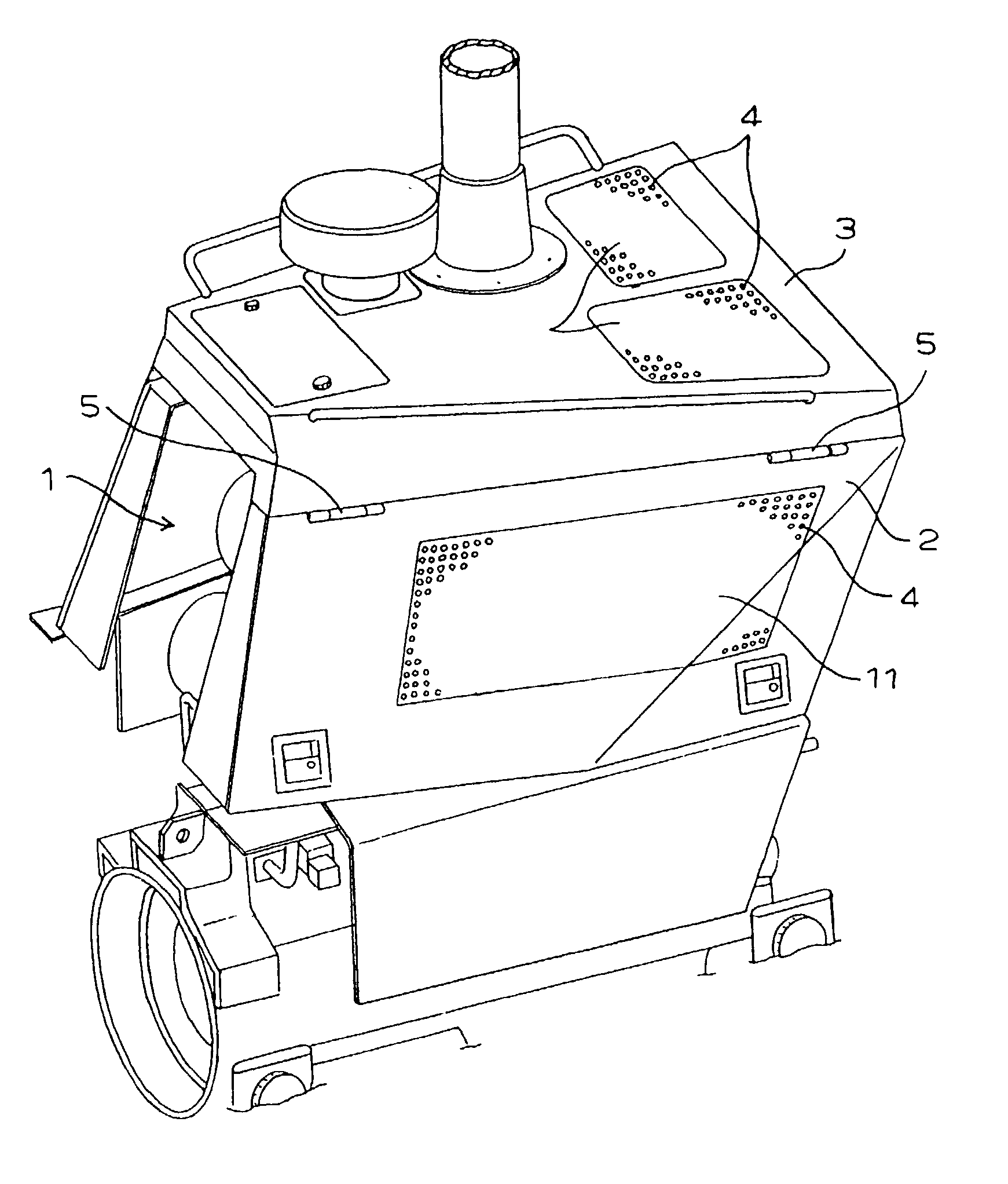

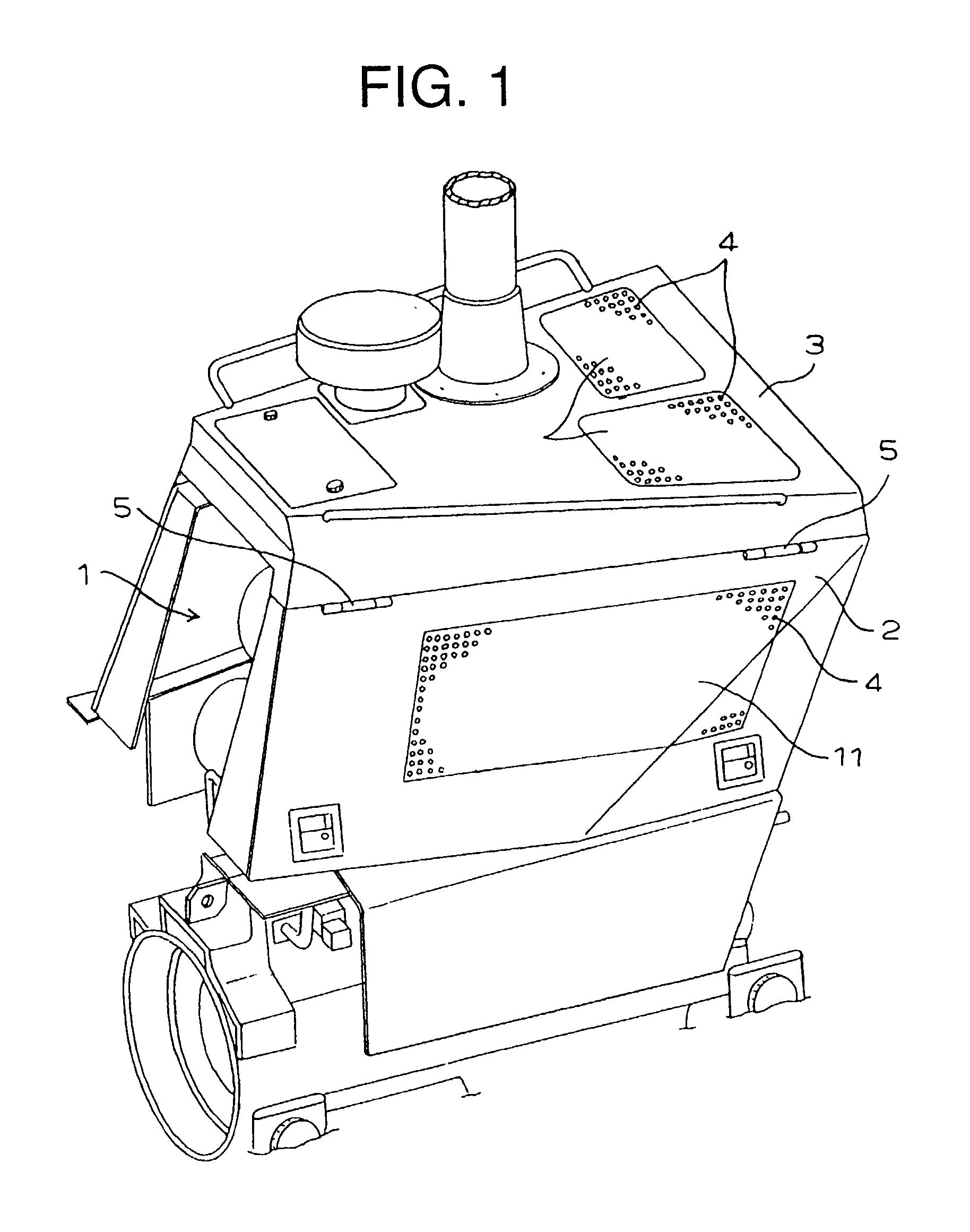

[0035] FIG. 1 schematically shows a perspective view of side covers 2 and a hood 3 which cover an engine compartment 1. The side covers 2, which are on right and left sides, can be opened and closed respectively by hinges 5. The side cover 2 is attached with a metal plate 11, which is provided with a plurality of punch holes to form vents 4. In place of the punch holes, the vents may be a metal plate which is formed with a plurality of slit-like opening portions, or a mesh sheet material. Further, in place of using the metal plate, punch holes or slit-like opening portions may be formed directly on the side cover 2.

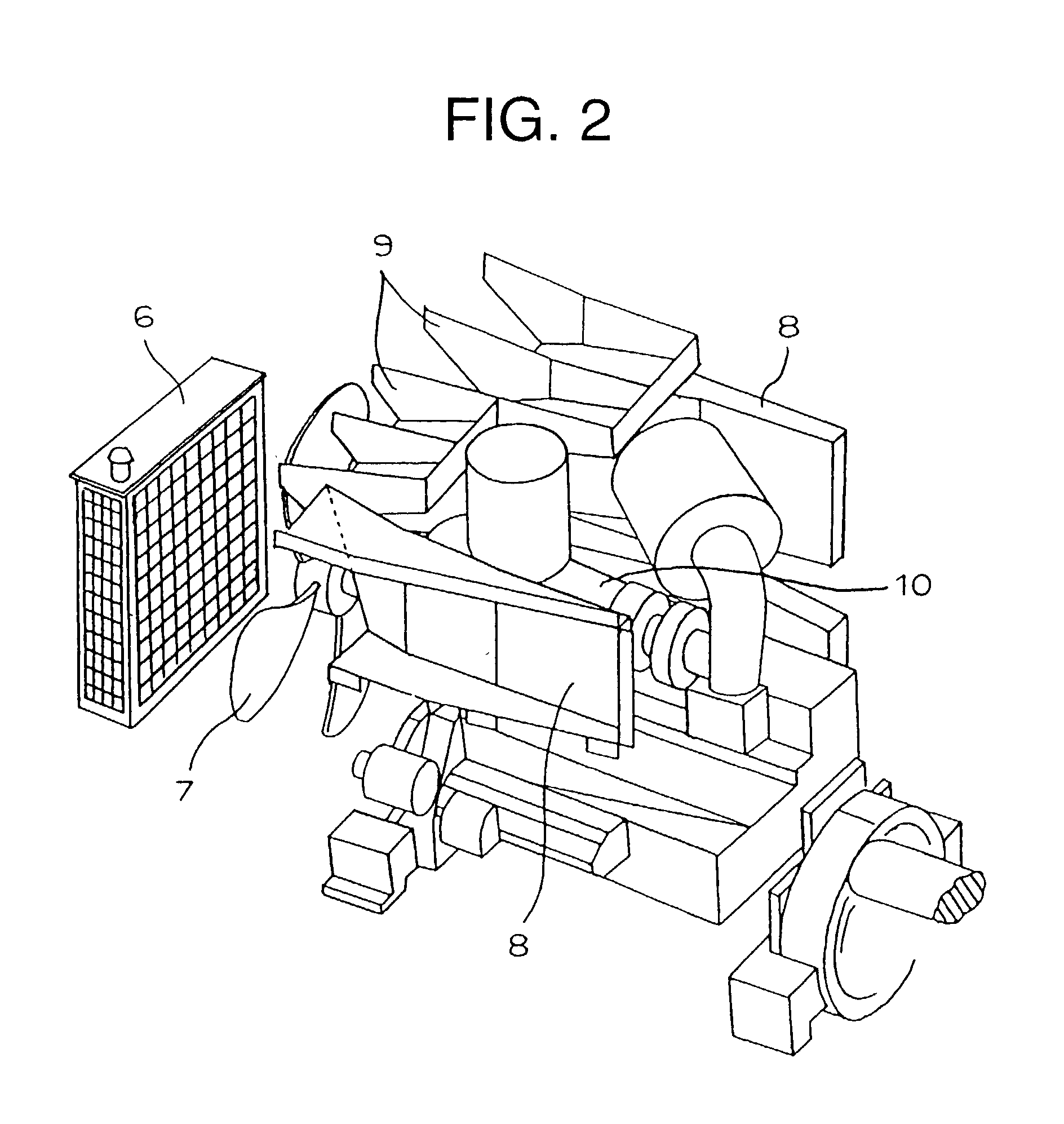

[0036] FIG. 2 schematically shows a perspective view of the inside of the engine compartment 1 from which the side covers 2 and the hood 3 are taken away. An engine 10 and the other devices are arranged within the engine compartment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com