Wheel action force detector for detecting axle forces absent brake torque

a technology of action force detector and axle force, which is applied in the direction of force/torque/work measurement apparatus, electric control, instruments, etc., can solve the problems of insufficient precision control of slip ratio, inability to obtain minimum braking distance, and inability to maximal braking force, so as to achieve easy measurement, reduce acceleration distance, and reduce braking distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The following are preferred embodiments of the invention and should by no means be construed as limiting the scope of the invention as defined in the claims.

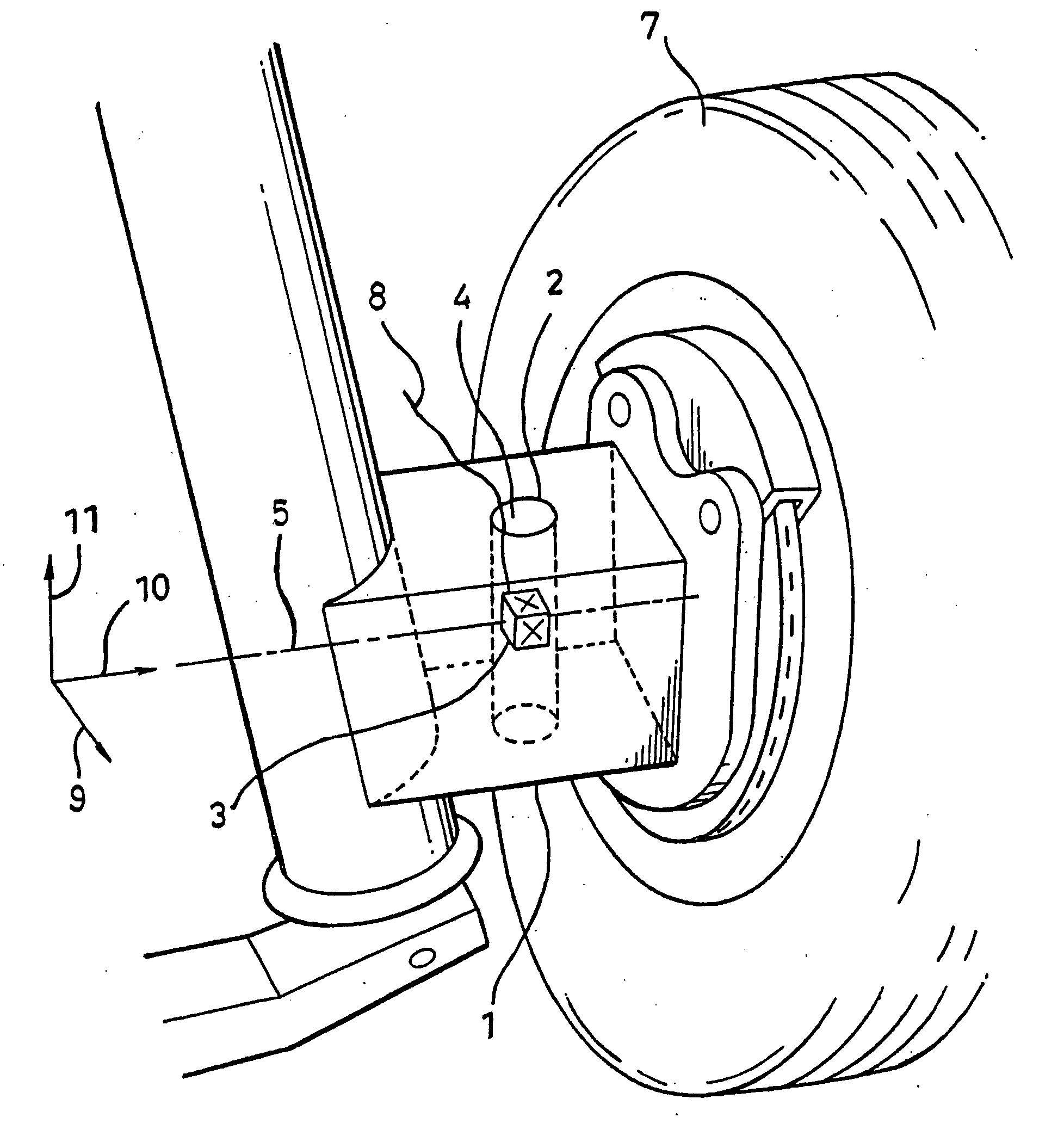

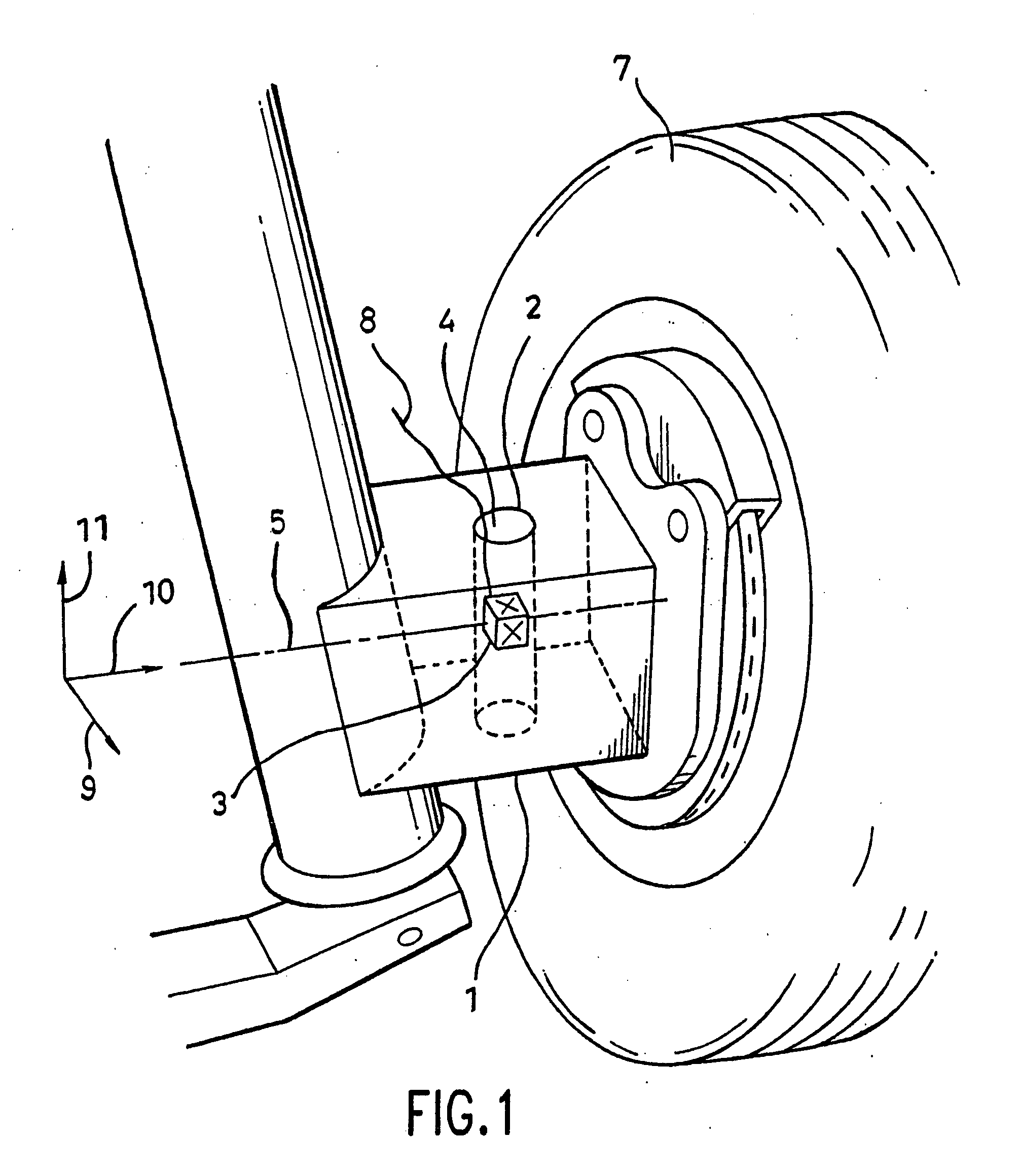

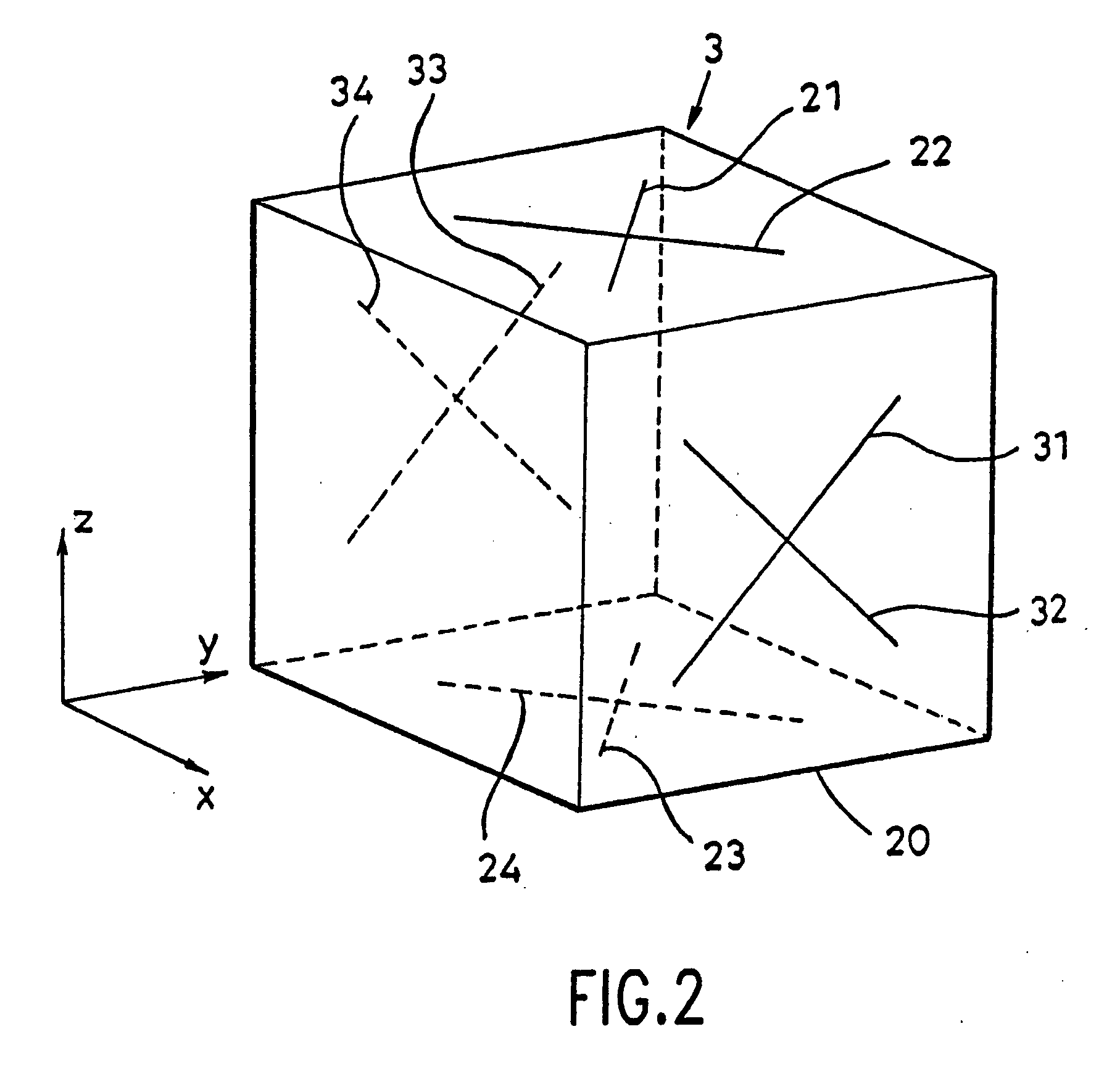

[0051] Specific examples of the device for measuring action force of a wheel for measuring the road surface friction coefficient are shown in FIGS. 1, 2 and 3. FIG. 1 shows the installation state of a stress detection sensor. FIG. 2 shows a stress detection sensor and FIG. 3 shows a signal processing circuit. As an example, there is shown the case in which the stress detection sensor is mounted in the axle of a driven wheel of a car having the strut type suspension structure which is often used in automobiles. From the top to the bottom of an axle (a knuckle in this example), a hole 2 is formed along a direction 11 perpendicular to the road surface and intersecting the centerline (stress neutral line) of the axle. The diameter of the hole 2 may for example be about 5 mm to about 10 mm. Here, the axle centerline (stress ne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| road surface friction coefficient | aaaaa | aaaaa |

| road surface friction coefficient | aaaaa | aaaaa |

| road surface friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com