Washing method in washing machine including semi-drying cycle and control apparatus therefor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Reference will now be made in detail to the embodiments of the present invention, examples of which are illustrated in the accompanying drawings. The embodiments are described below to explain the present invention by referring to the figures.

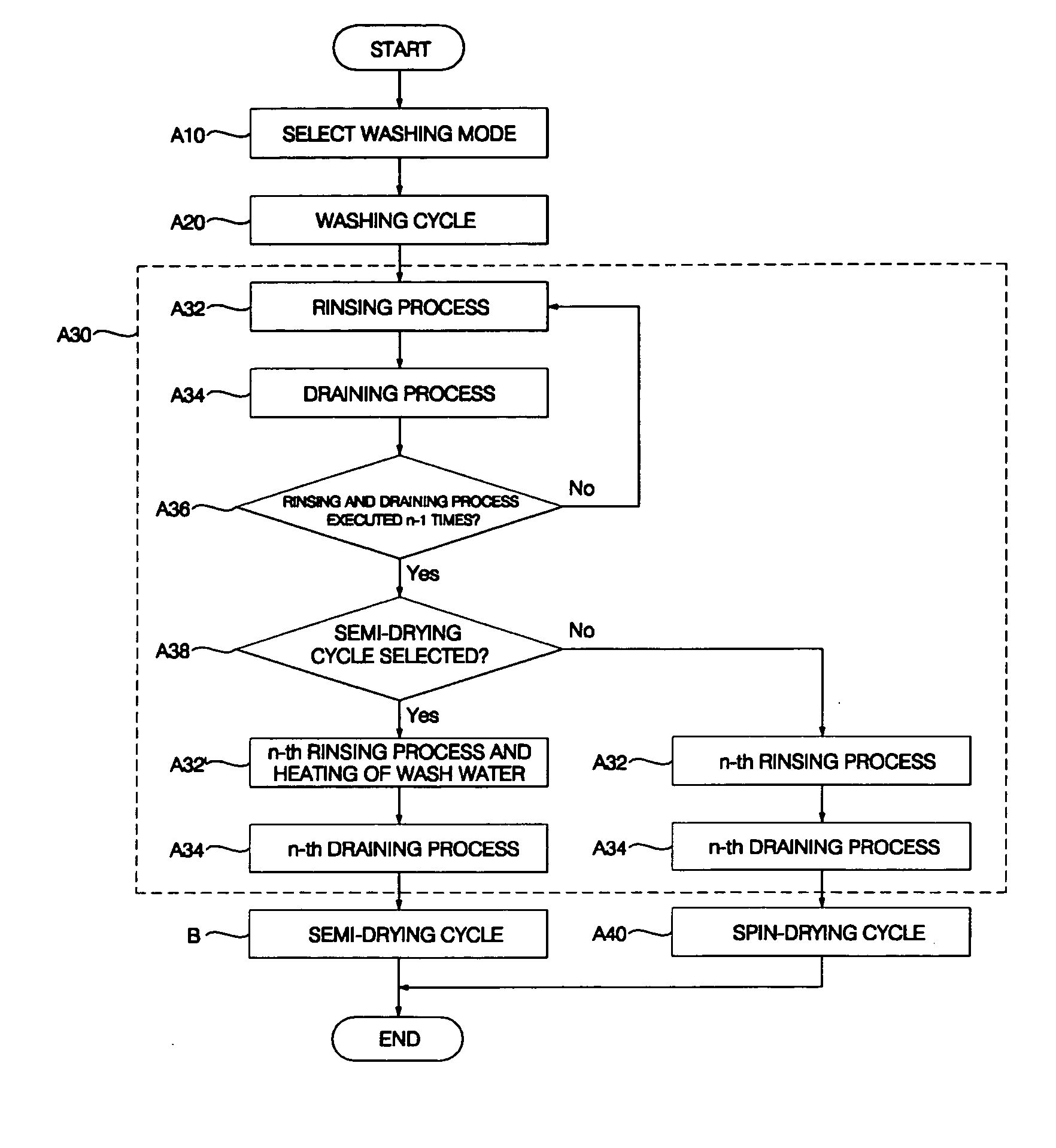

[0058]FIG. 3 is a flow chart illustrating a washing method in a washing machine, which includes a semi-drying cycle according to a first embodiment of the present invention.

[0059] This washing method will now be described in detail with reference to FIG. 3.

[0060] When a desired washing mode is selected through a control apparatus, which is shown in FIGS. 11 and 12 or FIG. 13, and adapted to allow the user to select a desired washing mode, and to display the progress of the selected washing mode (A10), a washing cycle A20 is first executed to remove stains from clothes, and a rinsing cycle A30 is subsequently executed to rinse the clothes with clean water. After completion of the rinsing cycle A30, a spin-drying cycle A40 adapted to ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com