Dust receptacle of robot cleaner and a method for removing dust collected therein

a robot cleaner and dust receptacle technology, which is applied in the direction of suction cleaners, cleaning filter means, cleaning equipment, etc., can solve the problems of troublesome in both cases, inconvenient and conventional methods of removing collected dust, and difficult to remove dus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

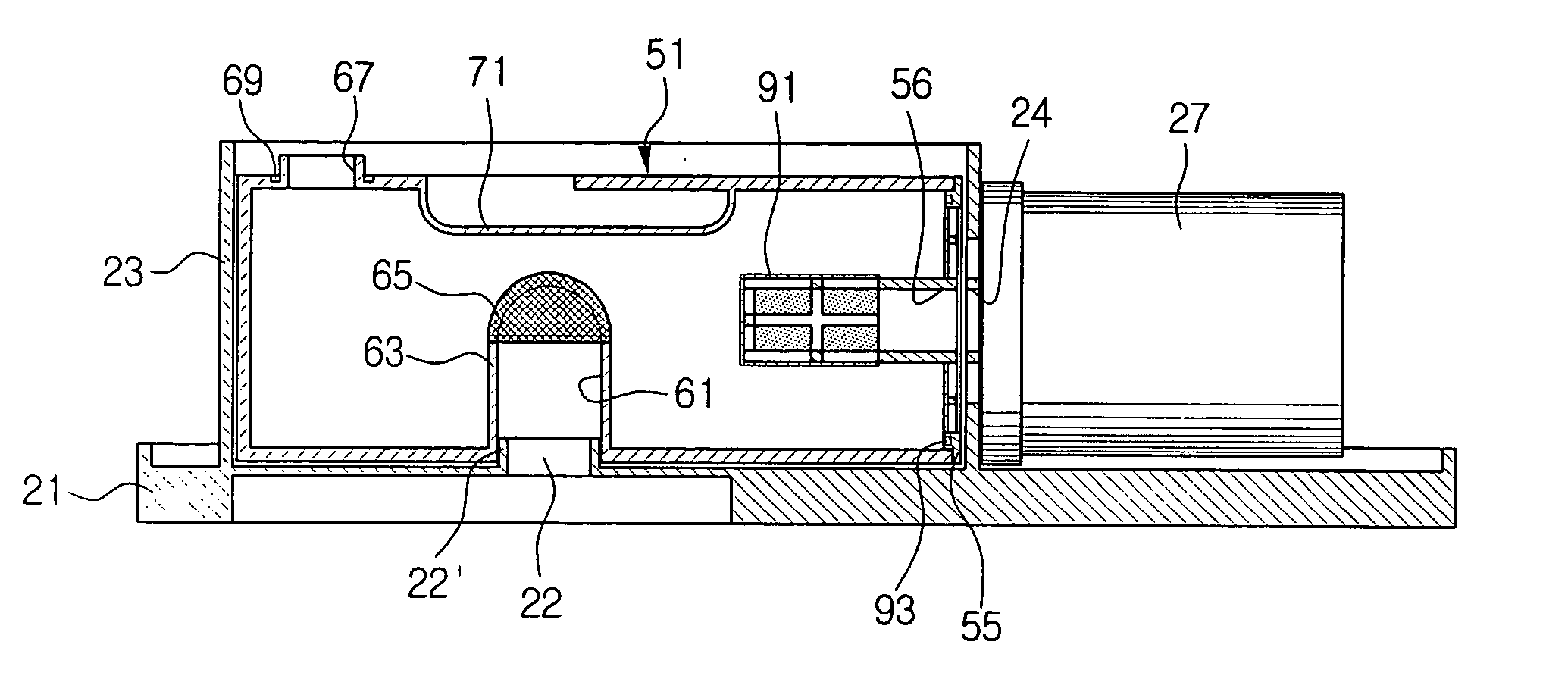

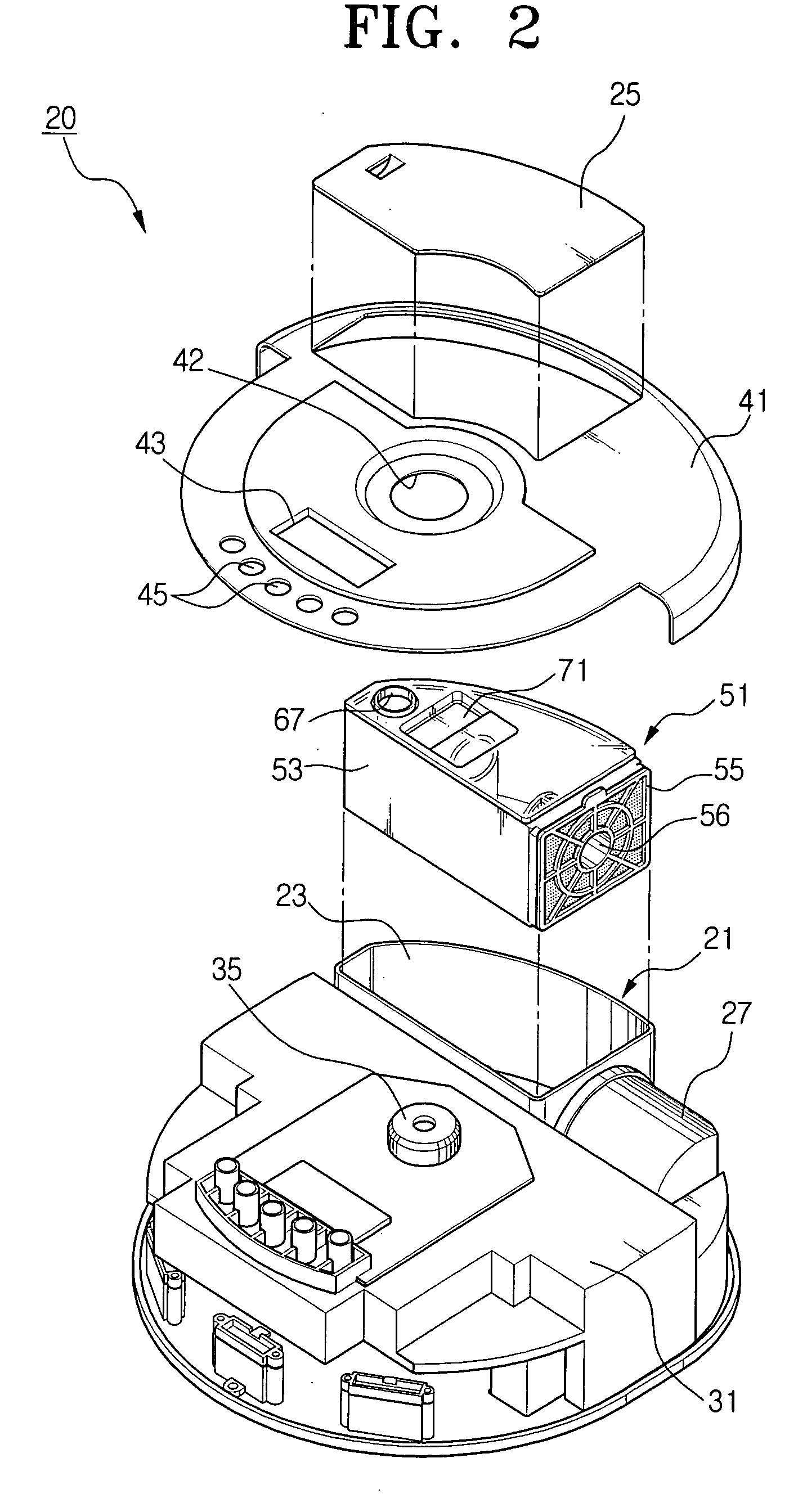

[0025] Hereinafter, an embodiment of the present invention will be described in detail with reference to the accompanying drawing figures.

[0026] In the following description, same drawing reference numerals are used for the same elements even in different drawings. The matters defined in the description such as a detailed construction and elements are nothing but the ones provided to assist in a comprehensive understanding of the invention. Thus, it is apparent that the present invention can be carried out without those defined matters. Also, well-known functions or constructions are not described in detail since they would obscure the invention in unnecessary detail.

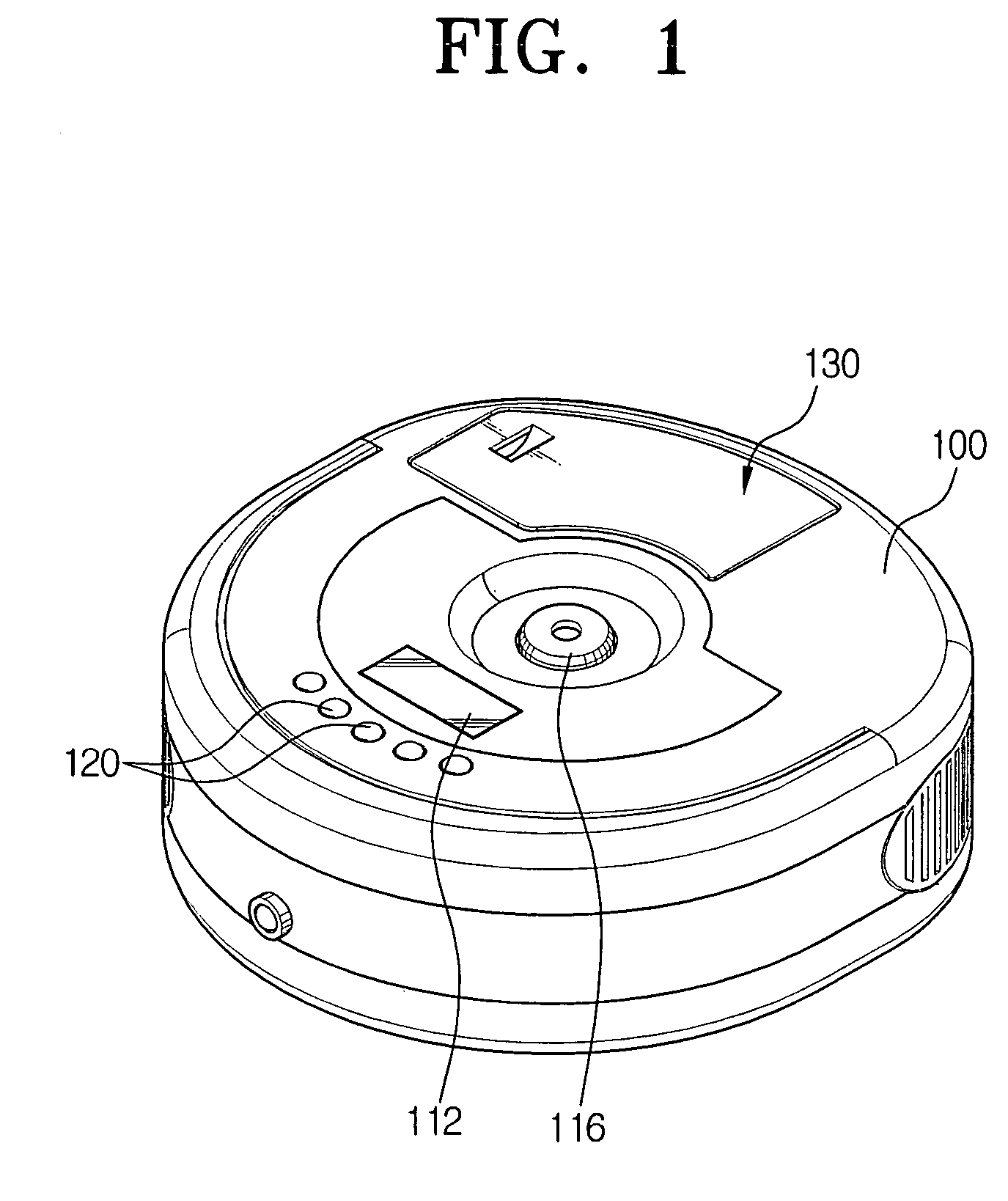

[0027]FIG. 1 is a perspective view of a robot cleaner applying a dust receptacle according to the present invention. The robot cleaner 20 has an upper casing 41. In a center of the upper casing 41, an image-capturing unit exposure hole 42 (FIG. 2) is formed, and at one side of the upper casing 41, a display window 43 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com