Masonry block anchor bolt assembly

a technology of anchor bolts and masonry blocks, applied in the direction of screws, threaded fasteners, mechanical equipment, etc., can solve the problems of grout seeping general practice not meeting specific code requirements, and grout leaking onto the front face of the masonry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will now be described more fully hereinafter with reference to the accompanying drawings, in which a preferred embodiment of the invention is shown. This invention may, however, be embodied in many different forms and should not be construed as limited to the embodiment set forth herein. Rather, this embodiment is provided so that this application will be thorough and complete, and will fully convey the true scope of the invention to those skilled in the art.

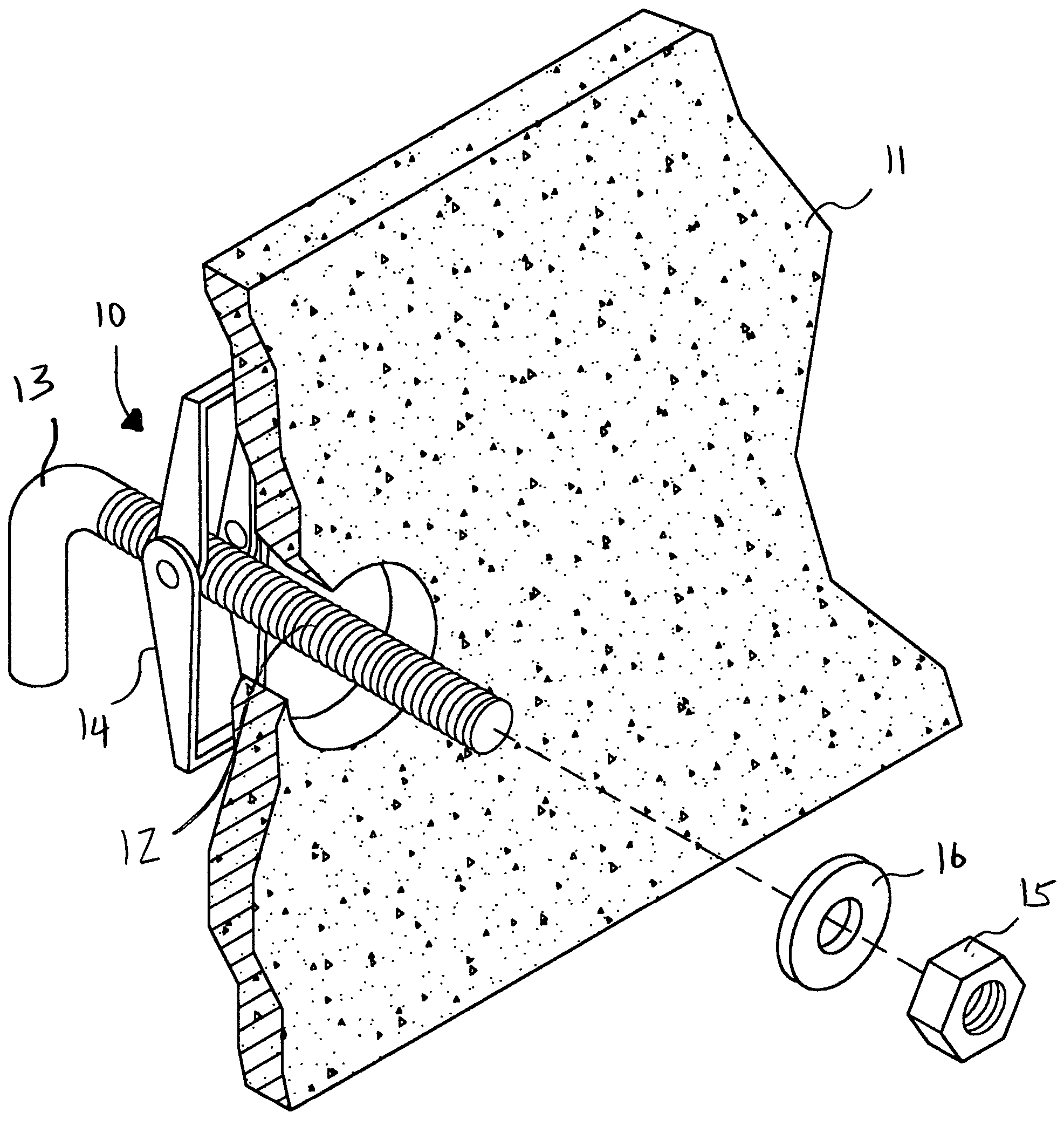

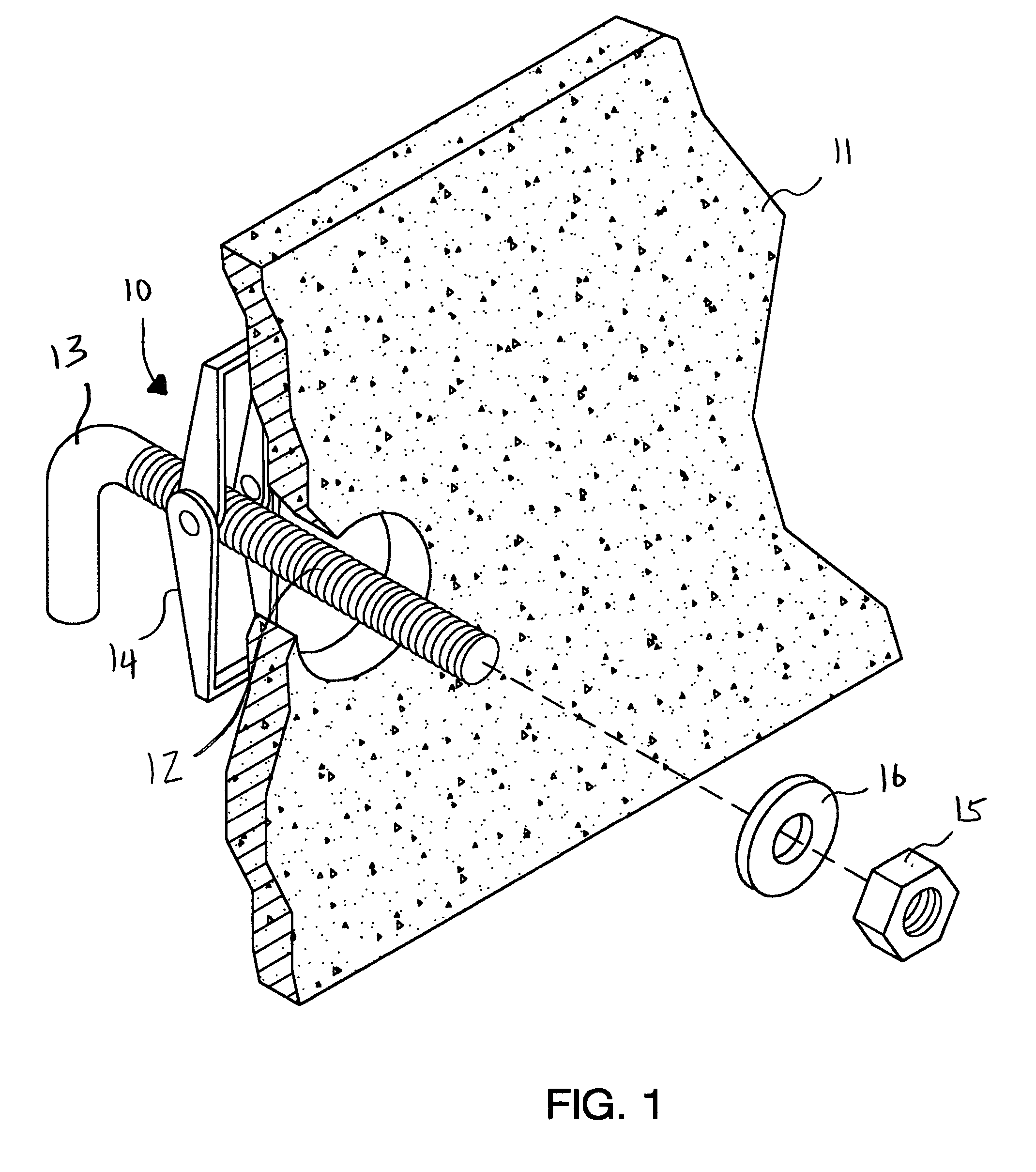

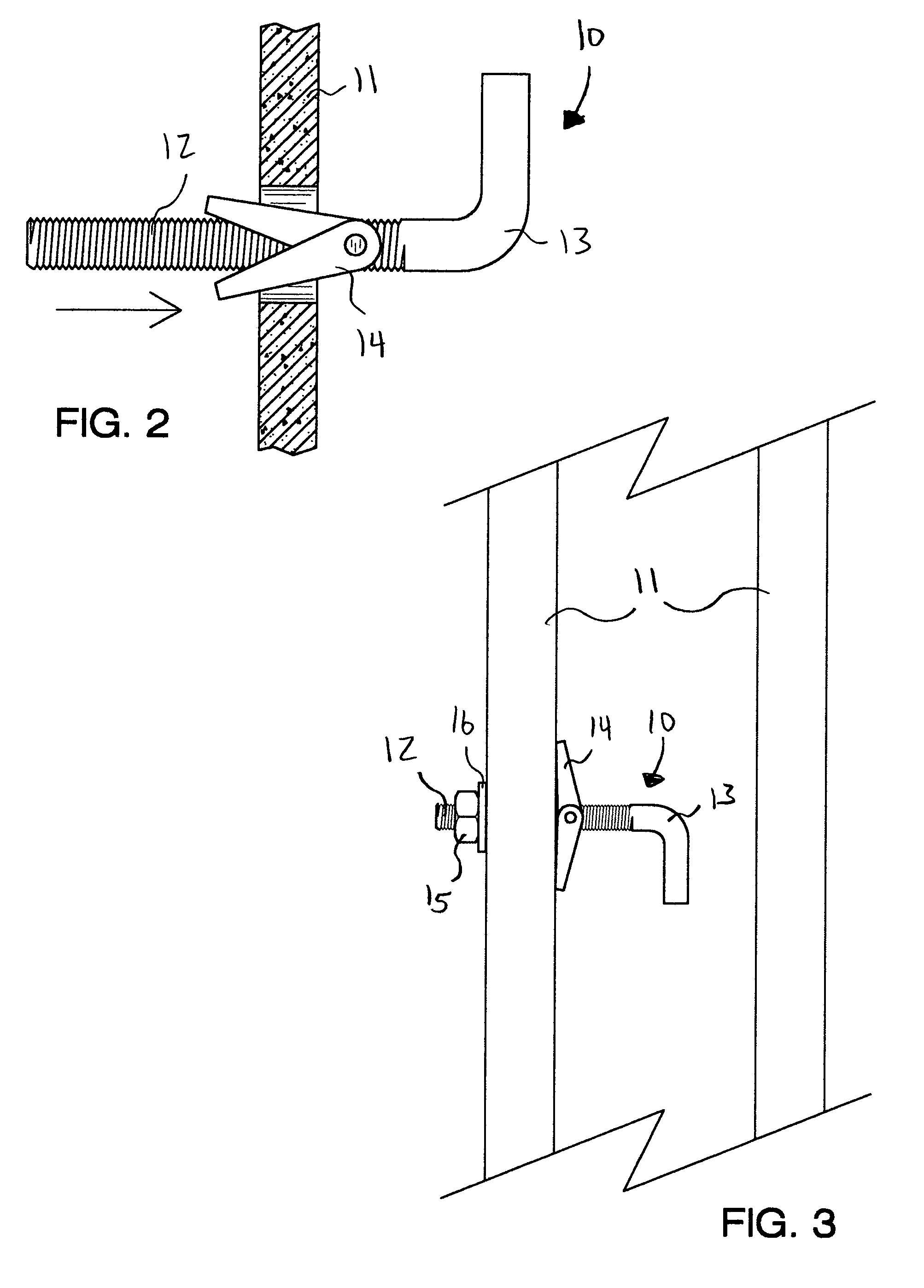

[0021] The assembly of this invention is referred to generally in FIG. 1 by the reference numeral 10 and is intended to provide an anchor bolt for use in the construction industry. It should be understood that the assembly 10 may be used in a variety of industries and should not be construed as having limited application to only the construction industry.

[0022] The assembly 10 includes a bolt having an elongate portion 12 and an arcuate end portion 13 integral therewith. The arcuate end portion 13 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap