Ophthalmic lens with optimal power profile

a technology of power profile and ophthalmology, applied in the field of ophthalmology, can solve the problems of awkward back and forth between normal and intermediate lenses, inability to tolerate intermediate mono-vision by most individuals, and inability to adjust the power profil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] As used herein “manifest refraction” means a user's subjective best correction for an eye. The “manifest corrective refractive power” means a refractive power required for achieving a user's subjective best correction for an eye.

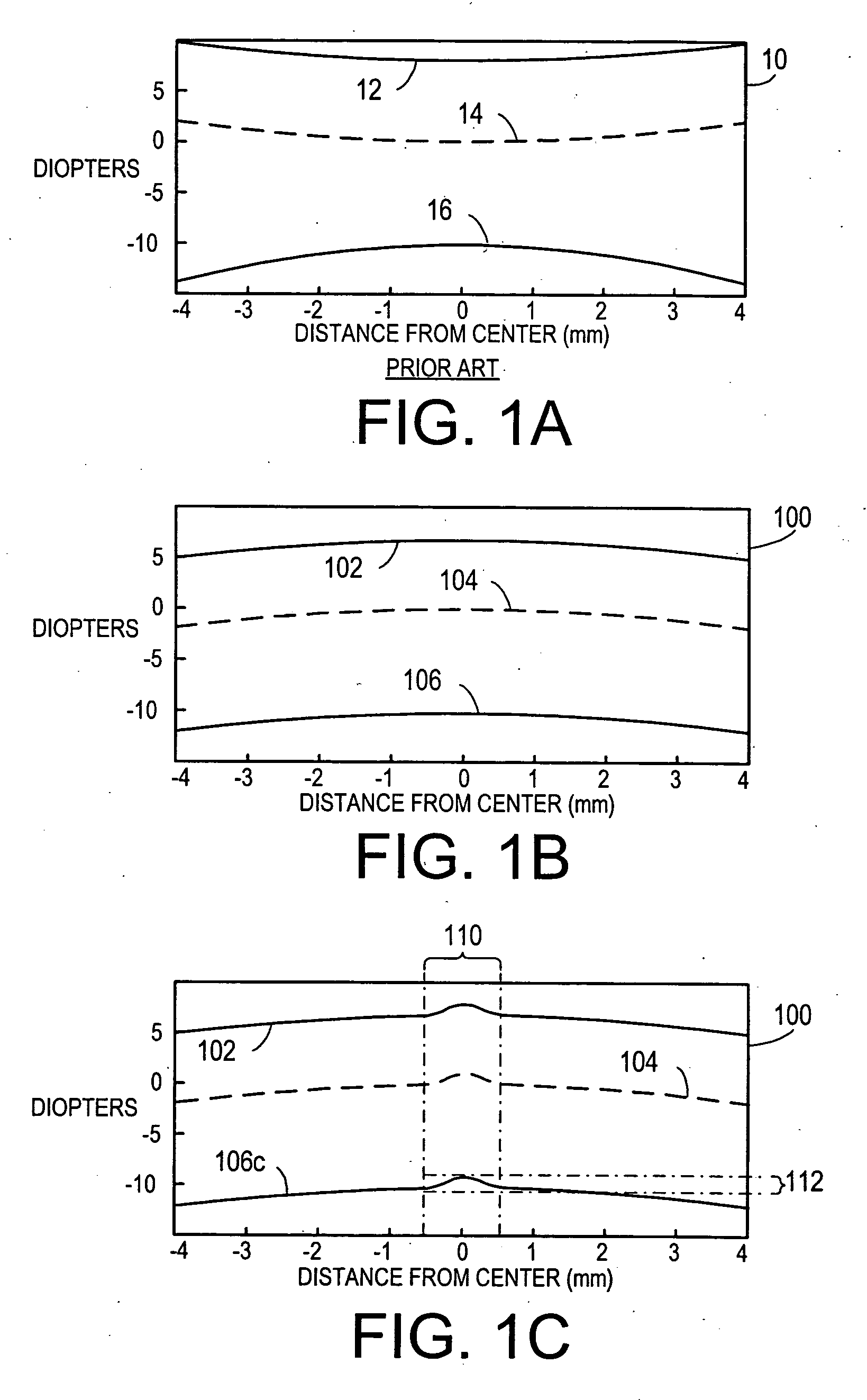

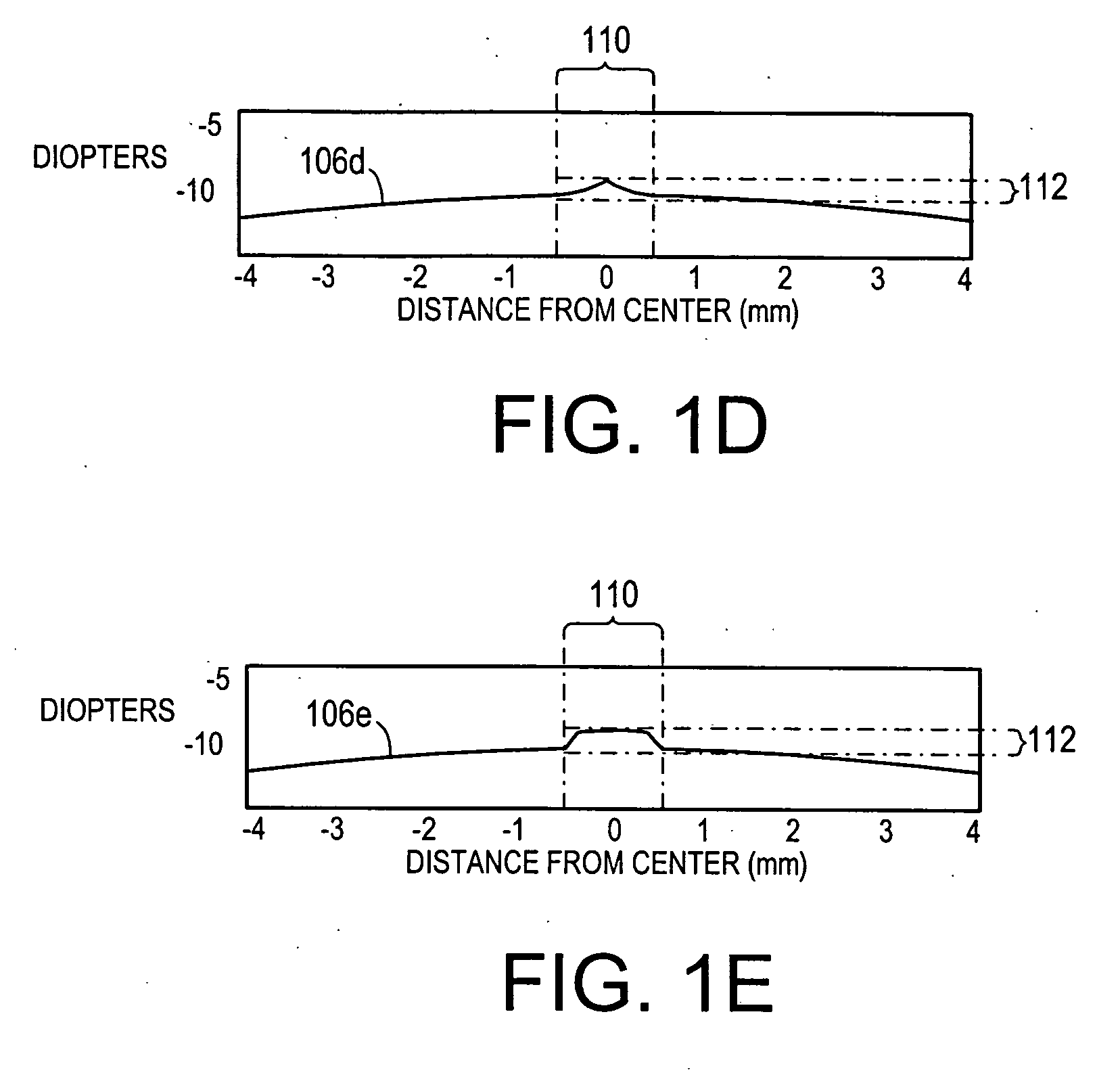

[0026] As used herein “negative spherical aberration” in reference to a lens means that the optical power decreases as the value of diameter increases. The amount of spherical aberration depends on the diameter. For a lens having a negative spherical aberration, its optical power at the center is larger than an optical power at any diameter. It should be understood that where a lens having a negative power (e.g., −6 diopters), its optical power at any diameter is more negative than its optical power at the center.

[0027] One embodiment of the invention is a lens that cancels the nominal amount of spherical aberration of the eye, which is approximately 1 diopter at a 6 mm diameter pupil for an adult, regardless of the eye's sphero-cylindrical manifest...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com