Apparatus for inflating and deflating

a technology of inflating and deflating apparatus, applied in the field of apparatus, can solve the problems of high cost and complicated process of conventional apparatus, and achieve the effects of simple and fast process, low cost, and simple and fast installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

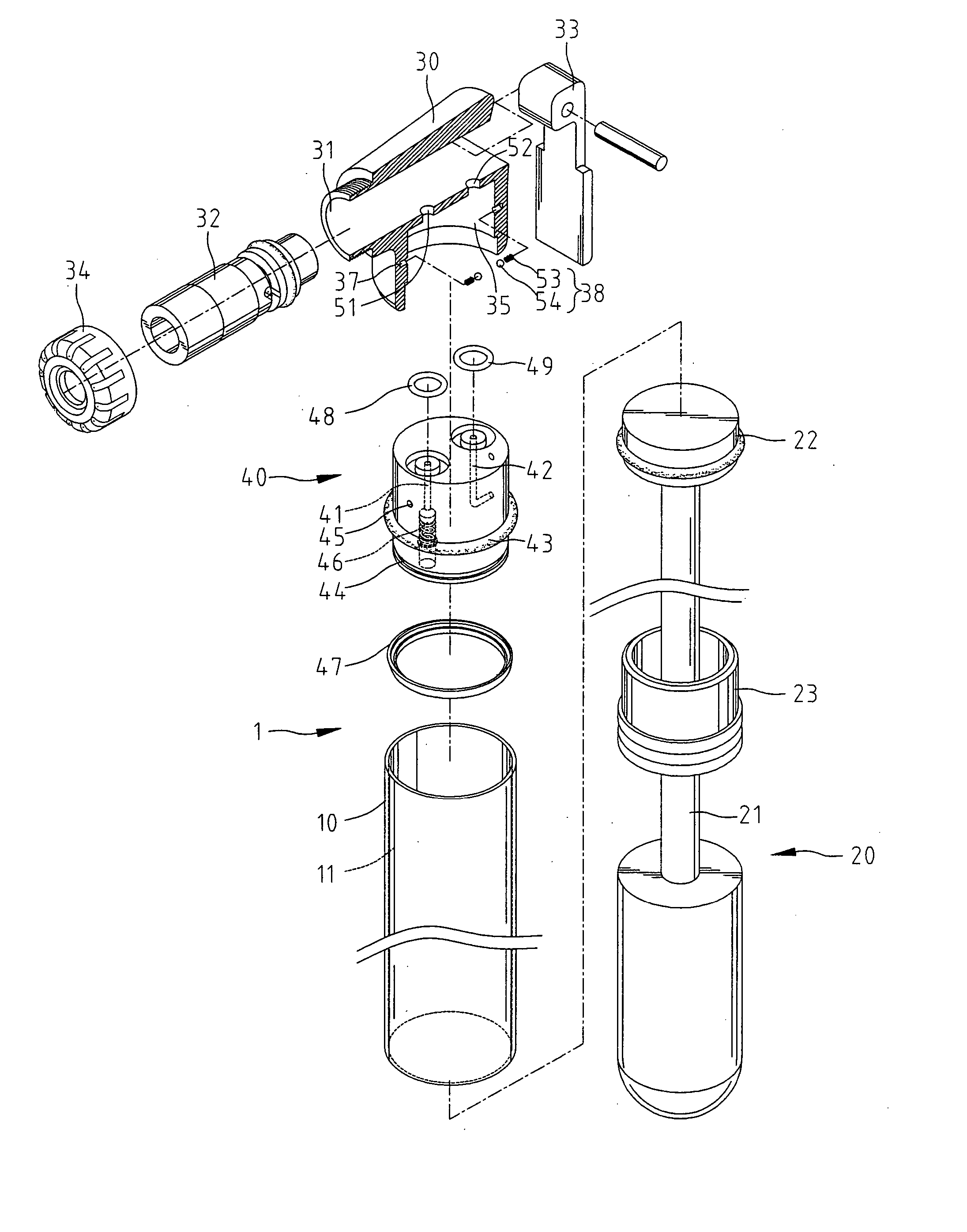

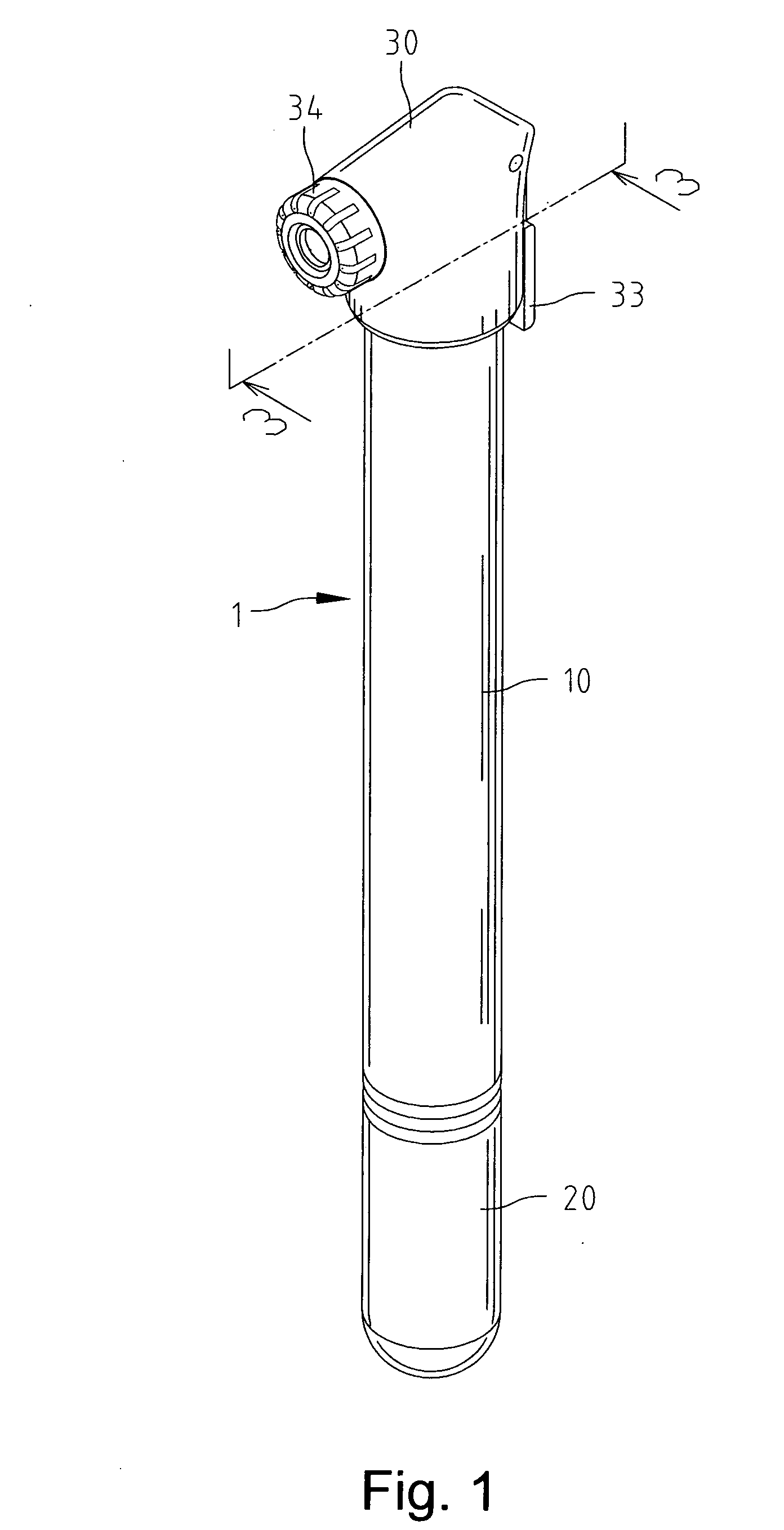

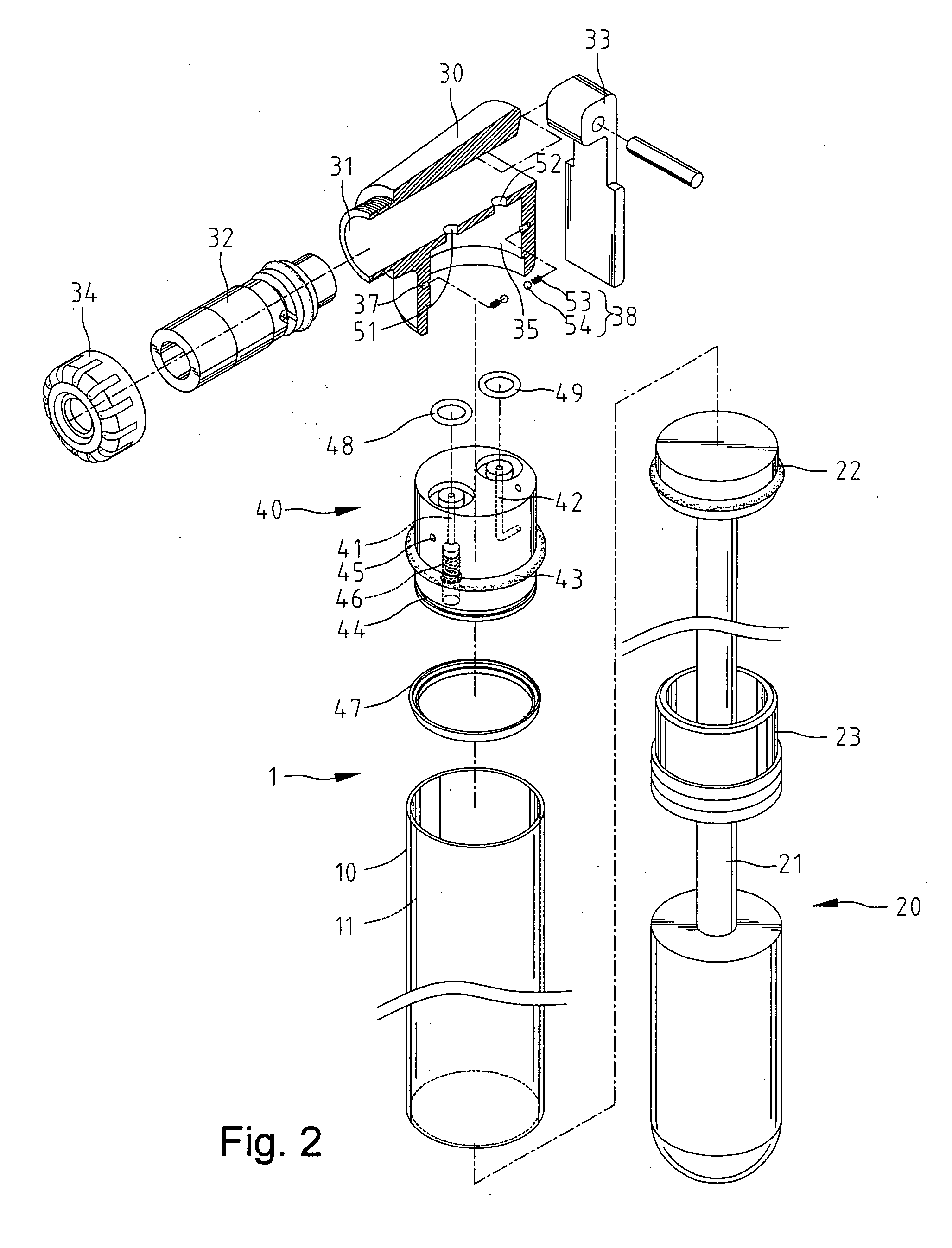

[0028] Referring to FIGS. 1 through 3, there is shown an apparatus 1 for inflating and deflating according to the present invention. The apparatus 1 includes a cylinder 10, a piston 22 put in the cylinder 10, a valve 40 provided on the cylinder 10 and a nozzle 30 provided on the valve 40.

[0029] The cylinder 10 defines a space 11 with a first open end and a second open end.

[0030] A piston rod 21 includes a first end connected with the piston 22 and a second end connected with a handle 20 for reciprocating the piston 22 in the cylinder 10. At the first open end of the cylinder 10, a seal 23 is provided between the cylinder 10 and the piston rod 21.

[0031] The block 40 is fit in the second open end of the cylinder 10. The block 40 defines a first passage 41 and a second passage 42. The first passage 41 extends from a first end of the block 40 to an opposite second end of the same. The second passage 42 extends from the first end of the block 40 to the periphery of the same. That is, t...

second embodiment

[0042]FIGS. 12 through 16 show an apparatus for inflating and deflating according to the present invention. The second embodiment is identical to the first embodiment except that the check valve 47 is arranged in an opposite direction. Accordingly, the second embodiment is operated in a different manner.

[0043] The apparatus 1 is ready for deflating. The first portion of the upper space 31 is communicated with the second passage 42 through the first aperture 51. The second portion of the upper space 31 is communicated with the first passage 41 through the second aperture 52. Although not shown, a valve of an inflatable object is inserted in the first portion of the upper space 31.

[0044] Referring to FIG. 13, the piston 22 is moved from the block 40. Air is drawn into the cylinder 10 from the inflatable object through the second passage 42. As best shown in FIG. 14, air cannot travel into the cylinder 10 from the exterior through the first passage 41 because of the check valve 46.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com