Retractable cover with biasing mechanism for covering structures

a technology of a sliding mechanism and a retractable cover, which is applied in the direction of curtain accessories, curtain suspension devices, building components, etc., can solve the problems of securing or storing the window or door cover, the process of manipulating the same cover for either or both use and storage, and the person getting cold or wet, so as to achieve convenient storage and protect from the elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

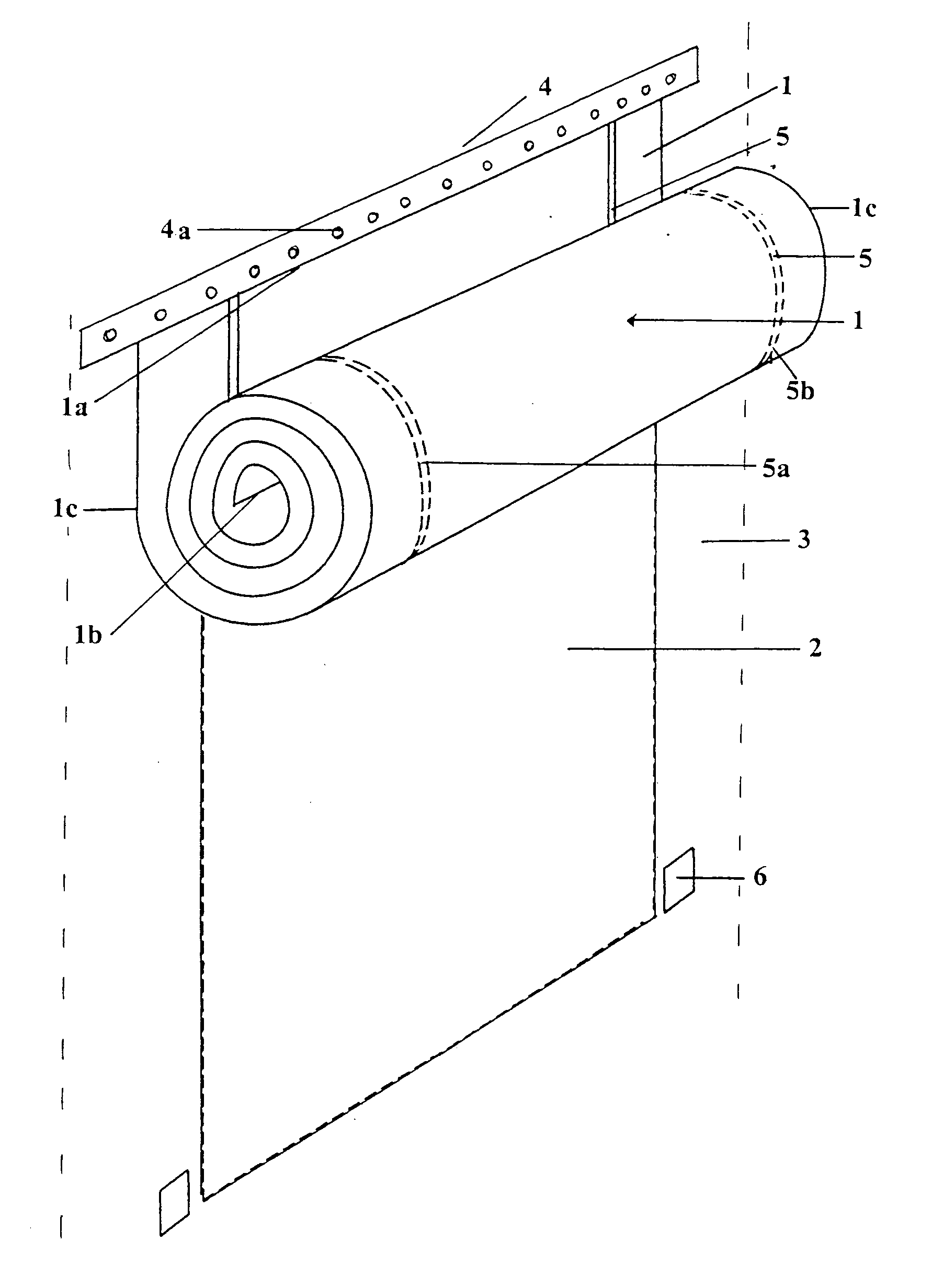

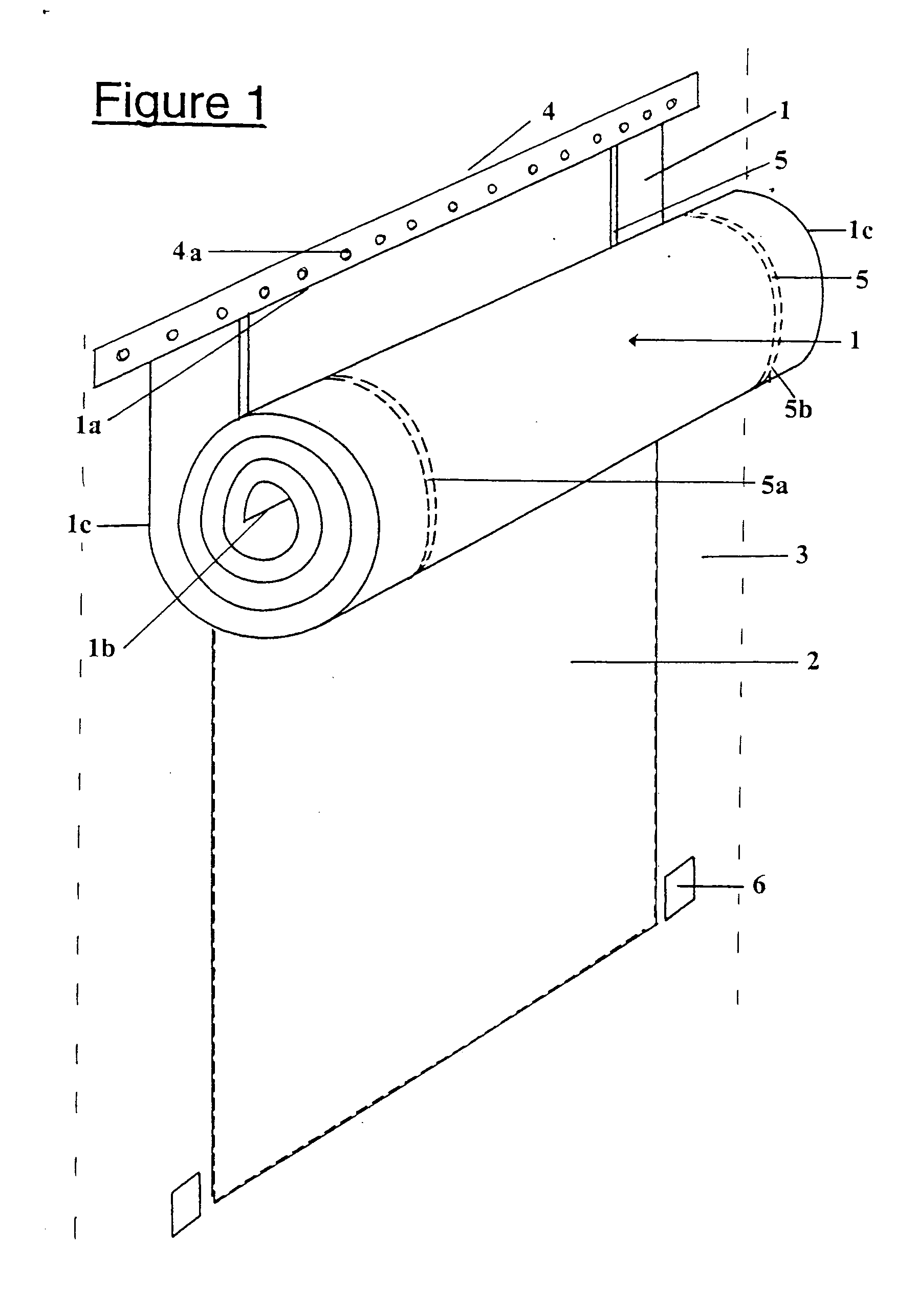

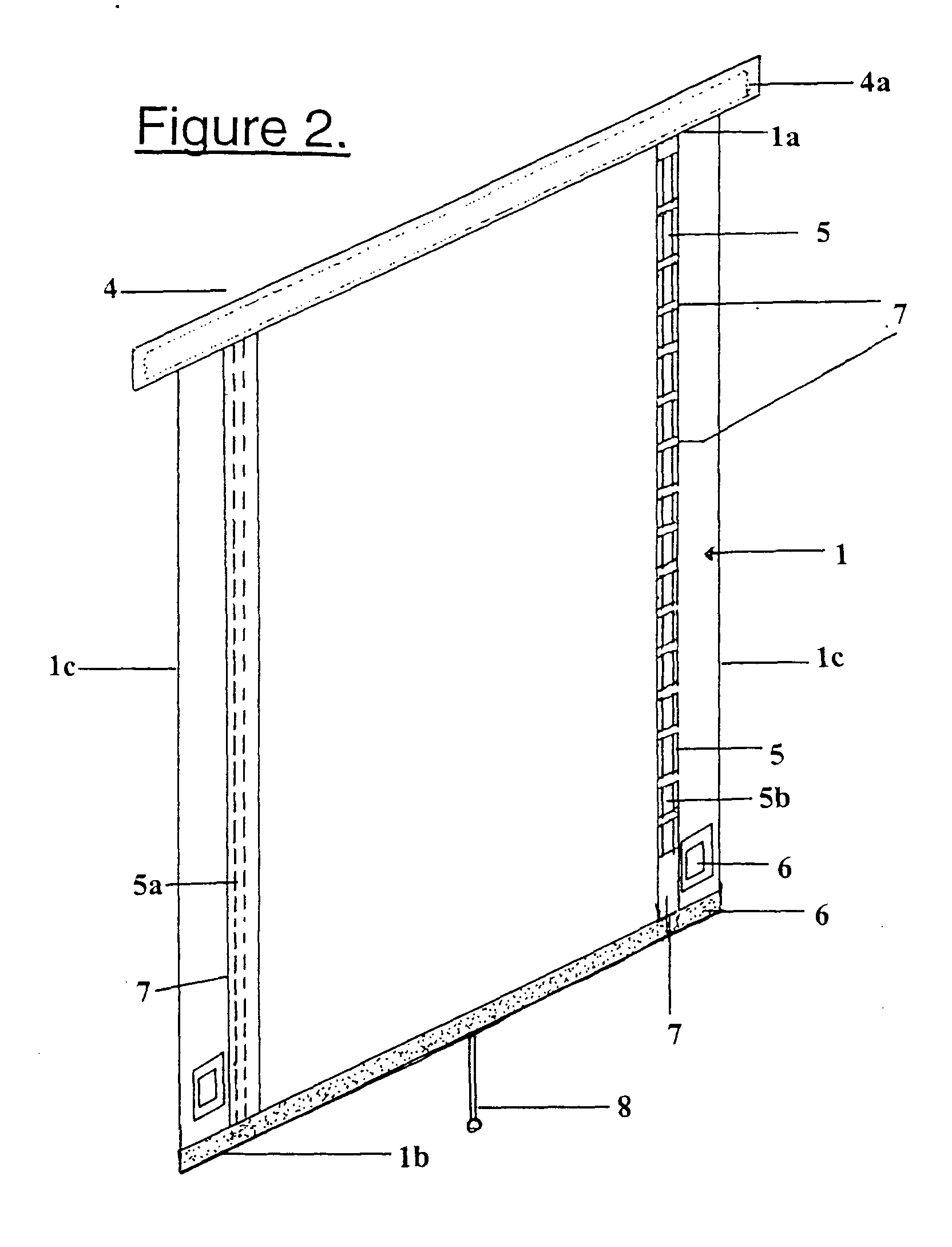

[0089] With reference to the diagrams by way of example only, there is provided a retractable cover 1 with biasing means 5 for covering structures 3.

[0090] The cover 1 as illustrated in FIG. 1 is made from substantially flexible materials, such as fabric, canvas, plastic materials, rubber, and so forth. The cover 1 includes a top edge 1a, a bottom edge 1b, and two side edges 1c. The cover 1 is substantially rectangular in shape. However, the shape of the cover 1 is variable between embodiments and is dictated by the structure's size and shape with which the cover is used.

[0091] The cover 1 may be secured in relation to the structure, at any one or more of the edges of the cover, depending on the function the cover is designed to fulfill. The structure it is covering, in the illustrated example, is an opening 2, such as a window or doorway of a tent 3, for example. The cover is therefore secured to the surround adjacent the structure. In the illustrated examples, the cover is secur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com