Method and apparatus for aerodynamic/hydrodynamic testing of a model

a hydrodynamic and aerodynamic testing technology, applied in the direction of waterborne vessels, structural/machine measurement, vessel construction, etc., can solve the problems of affecting other measurements, affecting the flow, and unsatisfactory waves, so as to improve the aerodynamic and hydrodynamic testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

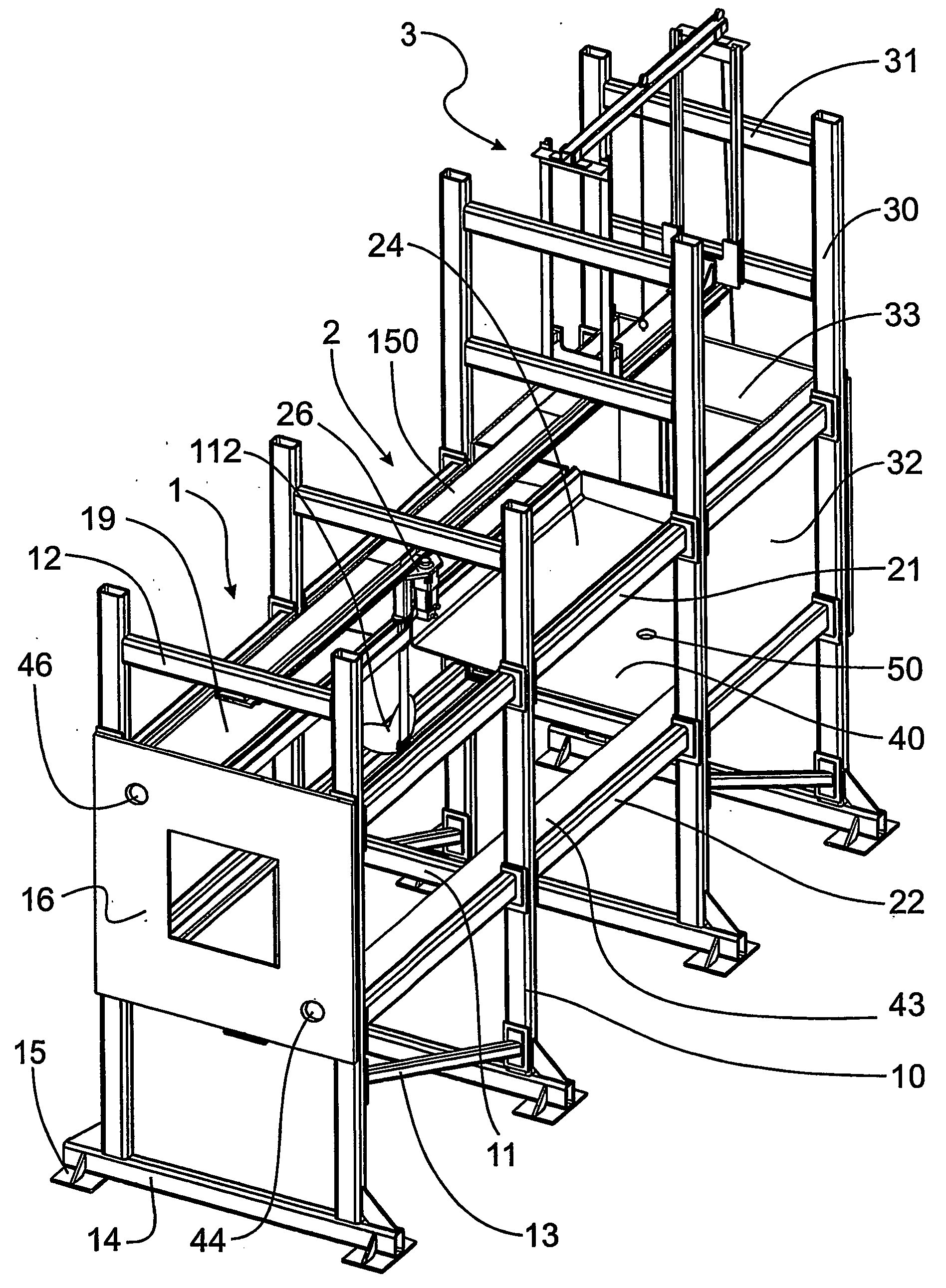

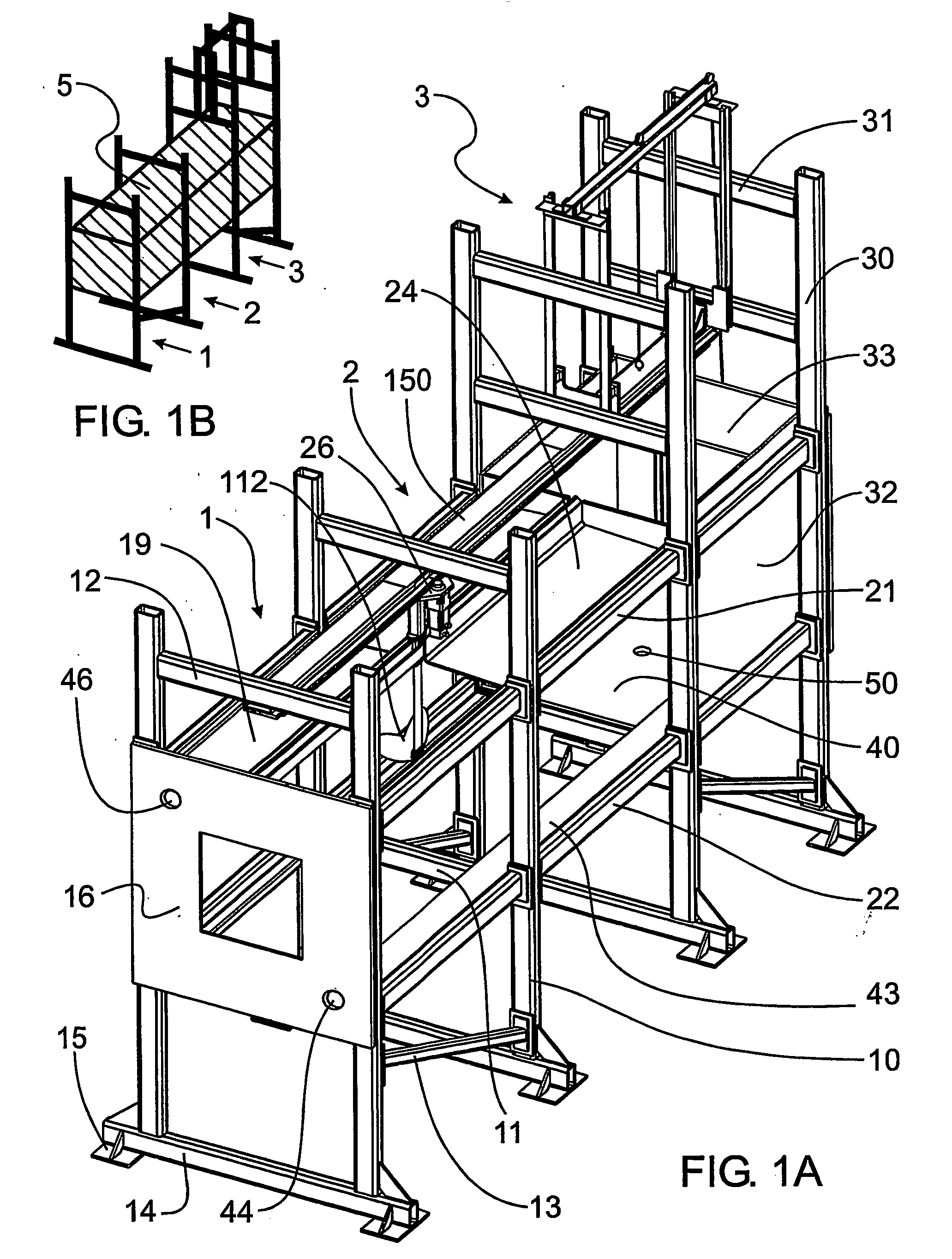

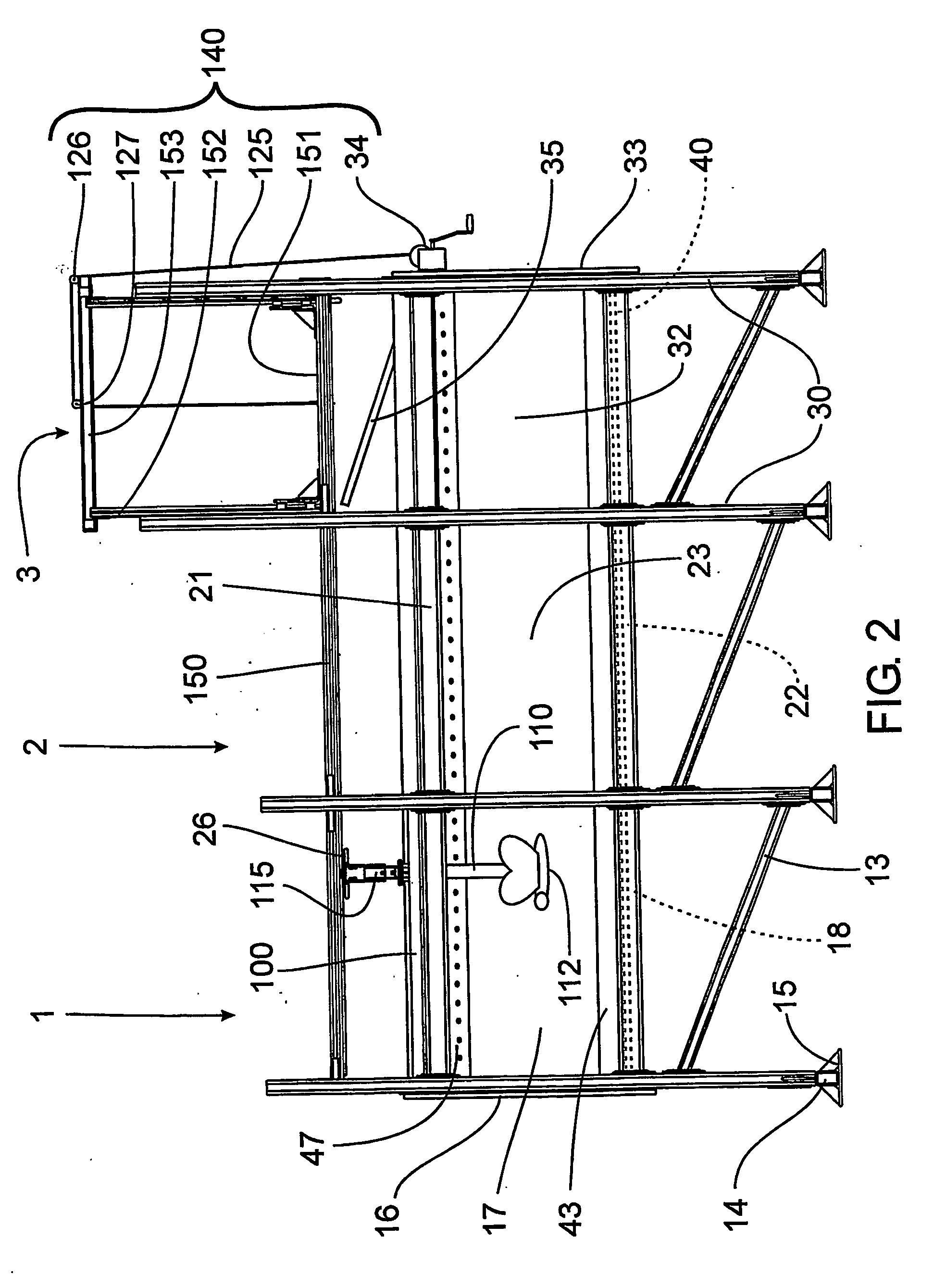

[0032] Generally, the present invention provides an apparatus, designed to conduct aerodynamic and hydrodynamic tests at very low Reynolds numbers, that addresses the problems encountered in conventional facilities when used under these conditions. The apparatus provides an enclosure for a test medium, which substantially eliminates any free surface between the medium and its surroundings, while permitting a model to move through the medium. The fluid contained in the tank is fully surrounded by and in contact with the walls, floor and roof, thereby substantially eliminating the possibility of a free surface. A method of using such an apparatus is also provided.

[0033] Preferably, the test medium is a mixture of two or more liquids where some have high viscosity and others have low viscosity, such that the viscosity of the test medium can be adjusted by changing the ratio between the components.

[0034] A first embodiment of the present invention is shown in FIGS. 1A, 1B, 2, 3A and 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com