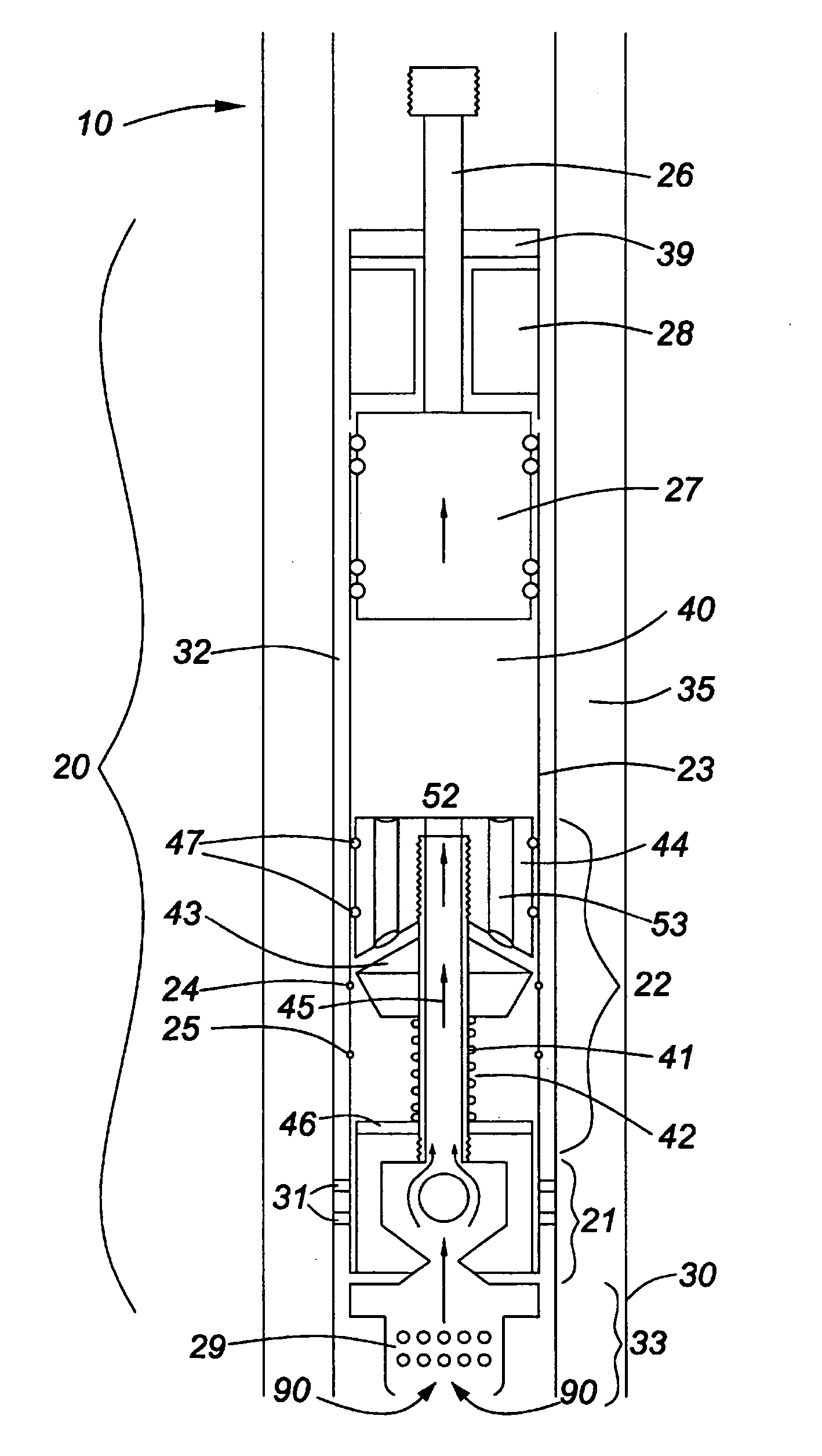

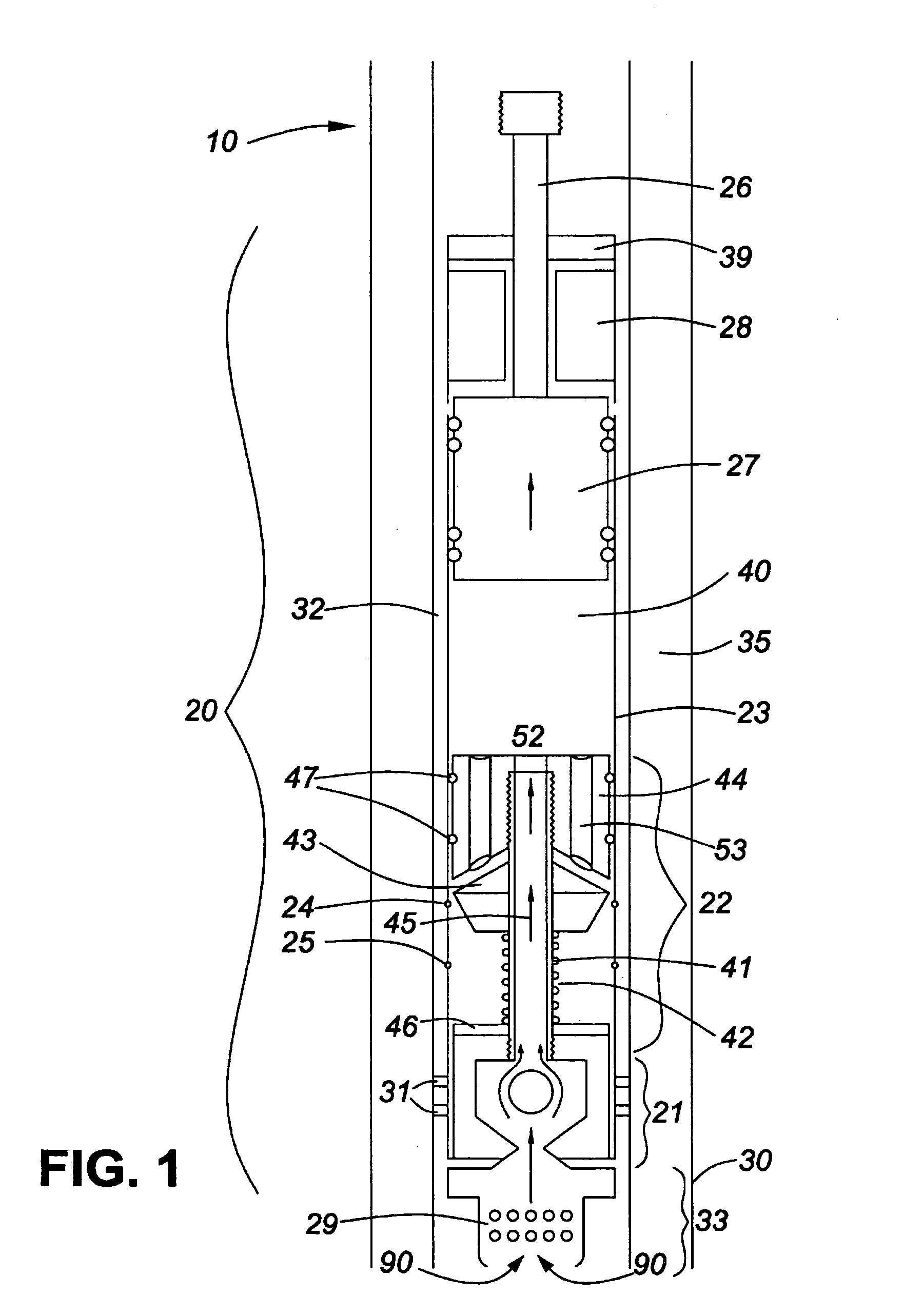

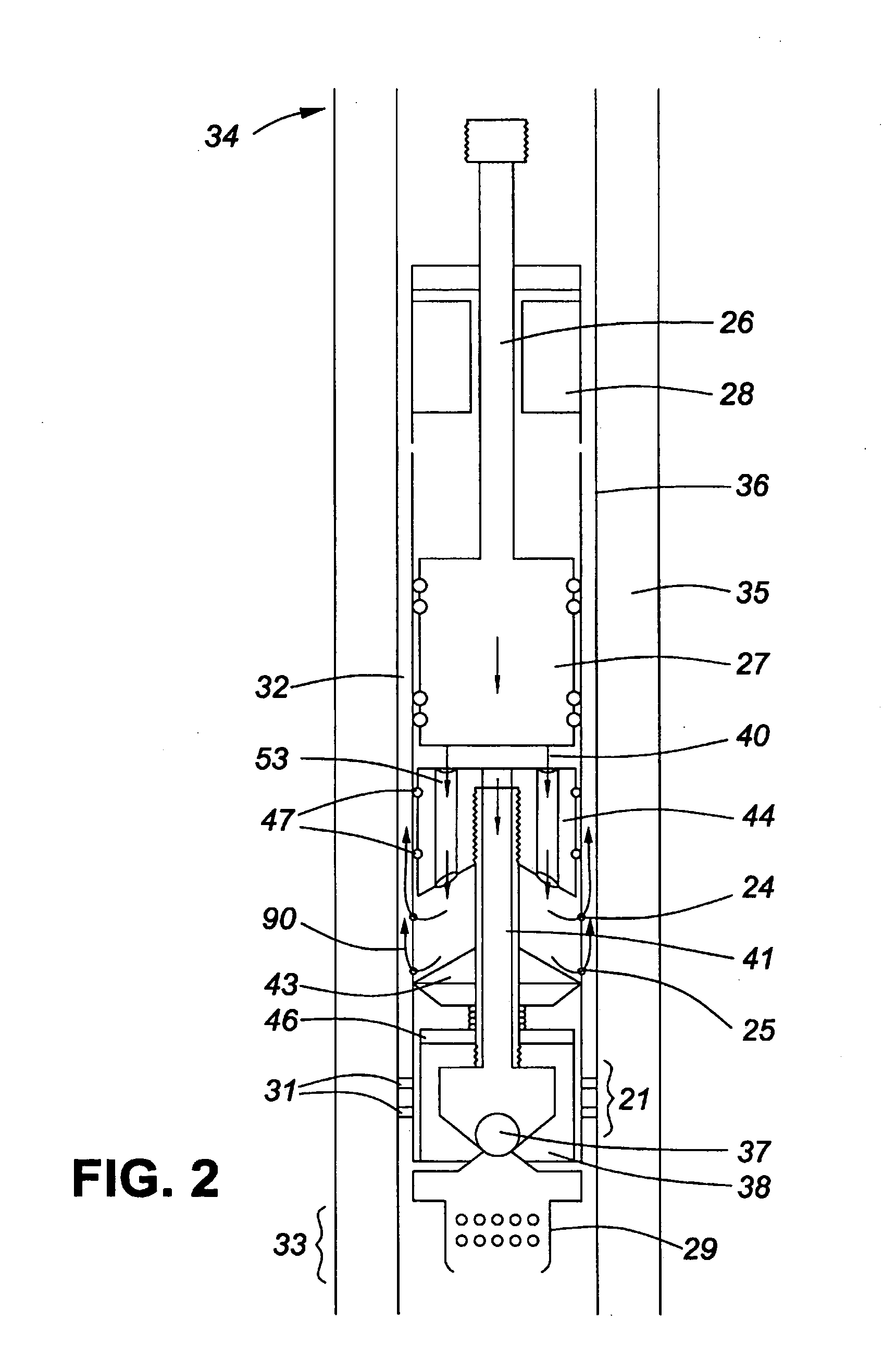

Anti gas-lock pumping system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

[0055] The anti gas-lock valve described above was placed within a pump into a downhole production well in Central Alberta, and was operated for 14 days. The pump produced 1000 L / h of oil, and maintained this efficiency for the entire duration of the test, indicating that the pump did not experience gas-lock. It was observed that both oil and gas were pumped into the annulus exterior of the pump barrel, to the top of the well. It was further evident that the entire contents of the pumping chamber was fully displaced with each downstroke of the plunger, this was also indicative that the pump would not be subject to gas locking.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com