Disposable self-shielding unit dose syringe guard

a self-shielding, syringe technology, applied in the field of syringes, can solve the problems of limiting the relative sliding relationship between the shield and the body, and achieve the effects of reducing manufacturing costs, preventing substantial lateral movement of the syringe within the body during use, and facilitating mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

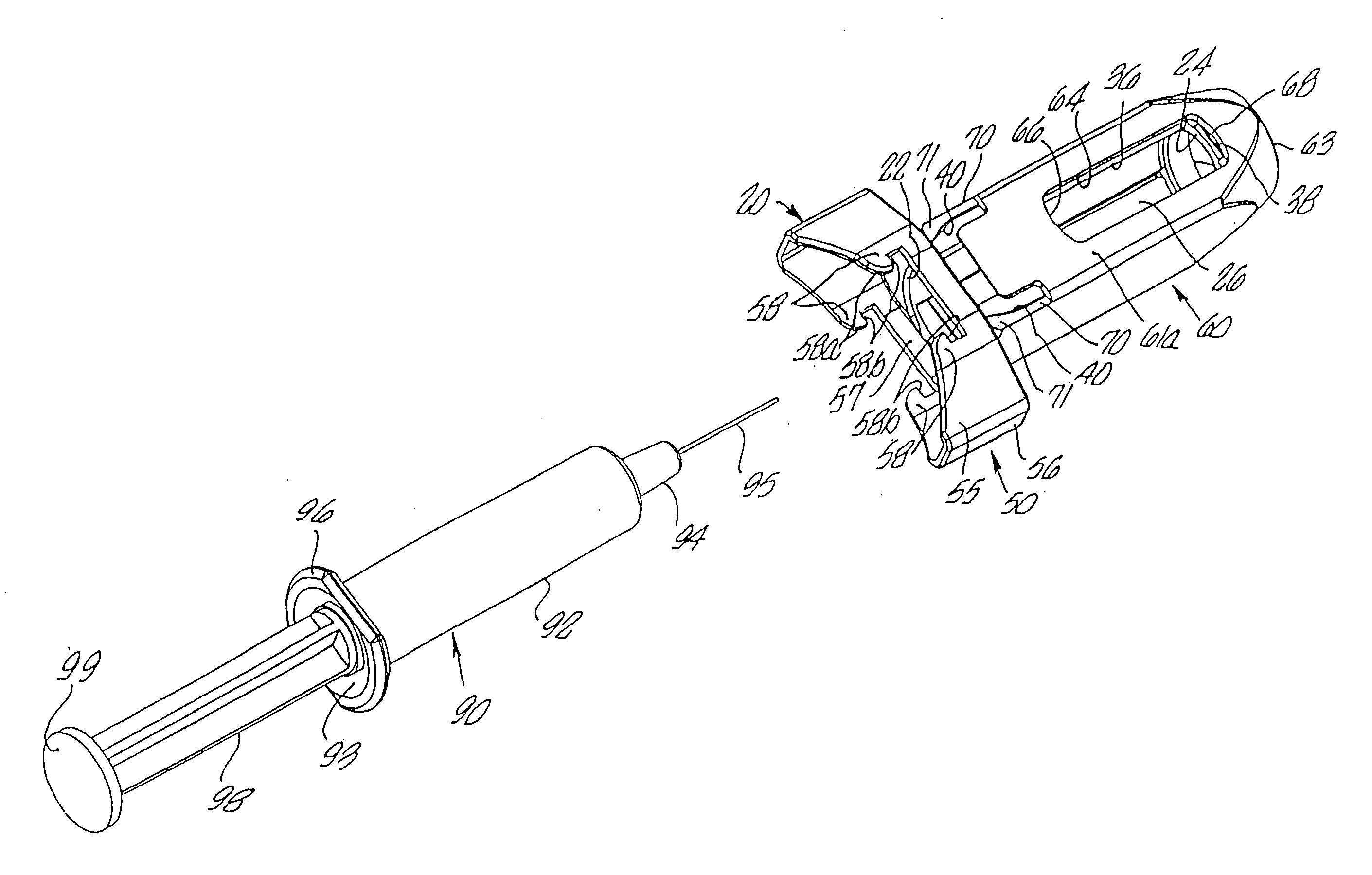

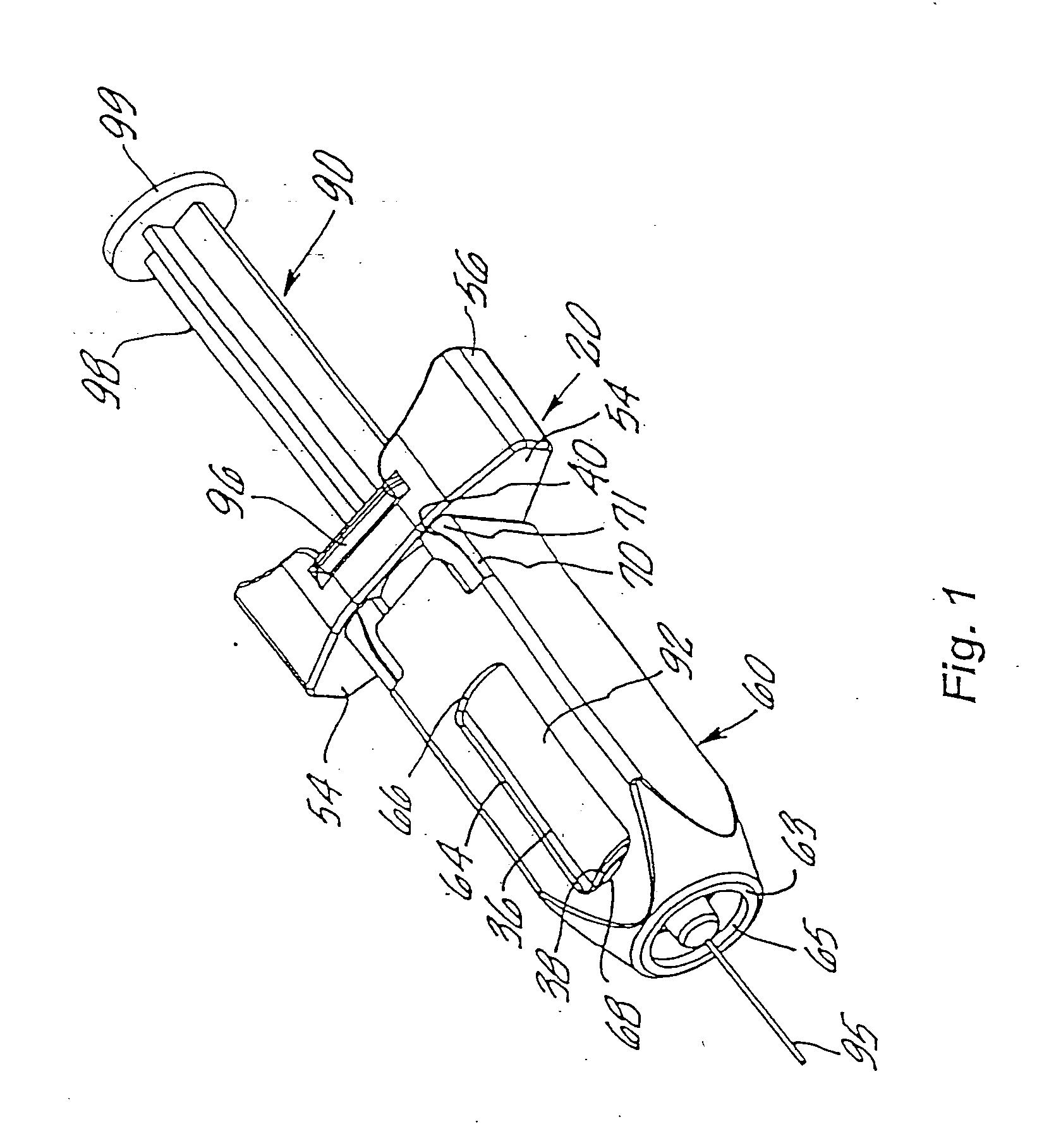

[0073] Turning to the drawings, FIG. 1 shows a first preferred embodiment of the present invention, namely a syringe guard 10 for holding a pre-filled unit dose syringe 90. Generally, the guard 10 comprises two-parts, namely a housing or body 20 for receiving and holding the pre-filled syringe 90, and a protective case or shield 60 slidably attached to the body 20. Both the body 20 and the shield 60 are generally molded from plastic, such as polypropylene, K-Resin®) (synthetic resinous polymers of butadiene and styrene), or polycarbonate, and are preferably clear and substantially colorless to facilitate observation of the pre-filled syringe received therein. Alternatively they may be translucent or opaque, and may be colored, such as a latex color, or a flesh tone, such as off-white, brown, or black.

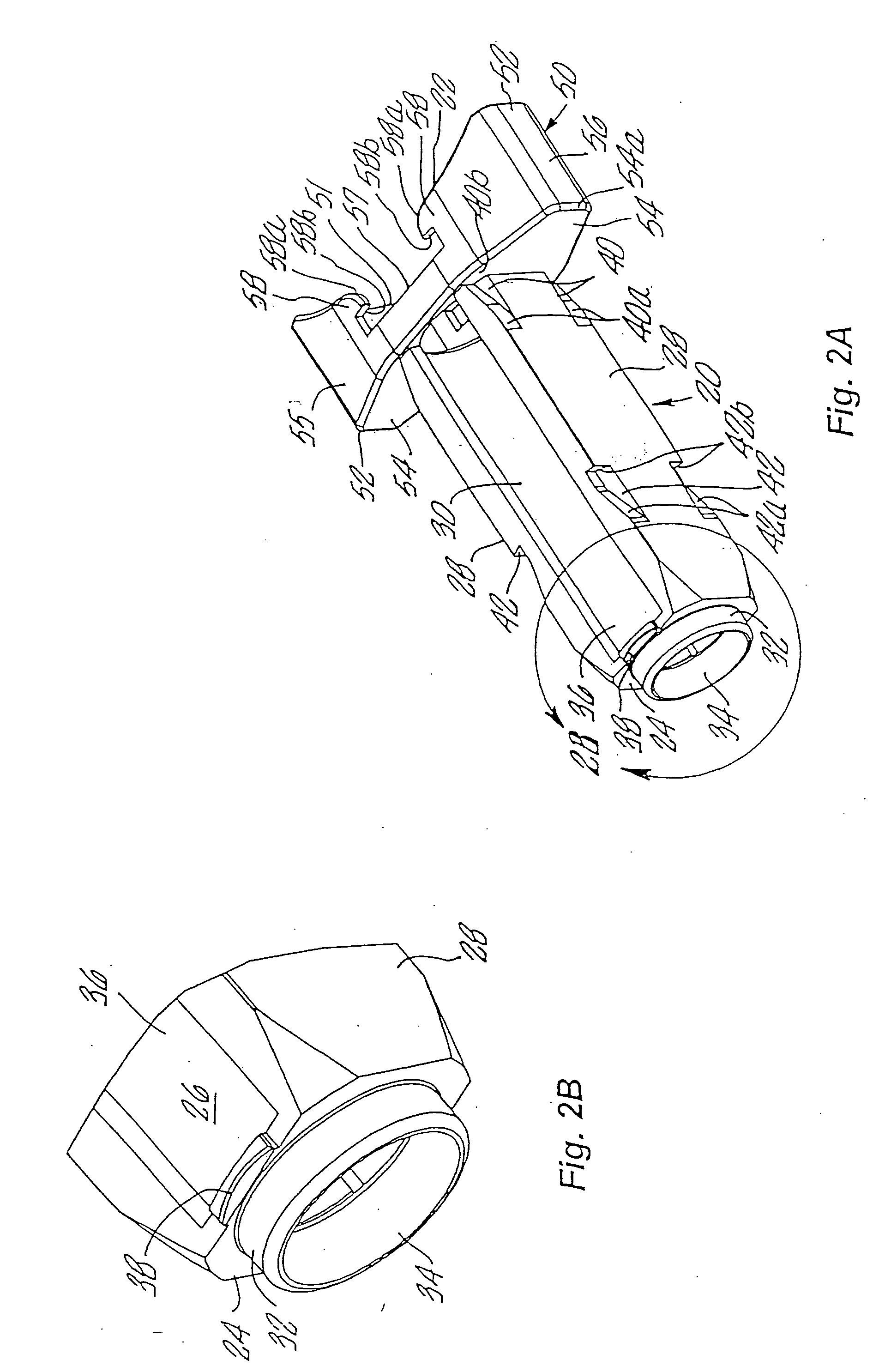

[0074] Turning to FIGS. 2A, 2B and 2C, the body 20 is an elongate member, preferably having a substantially rectangular cross-section, comprising two side rails 28, an open proximal en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com