Optical recording medium, recording material, method of producing optical recording medium, and optical recording, reading and rewriting method

a technology of optical recording medium and recording material, which is applied in the direction of optical recording/reproducing/erasing methods, instruments, and thermography, etc., can solve the problems of inability to obtain sufficient sensitivity for use in practice and degradation of reading optical stability, and achieve excellent preservation stability and reading optical stability. , the effect of high corresponden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0118] On a polycarbonate disk-shaped substrate with a groove having a track pitch of 0.74 μm and a depth of about 500 Å formed thereon, a recording layer was formed by use of a target with the composition of Sb74.0Te21.0Ge5.0 as shown in TABLE 1 by DC magnetron sputtering under the following conditions:

Back pressure:1 × 10−7 TorrGas used:ArApplied power:0.5 kWGas pressure:2 mTorr

[0119] On the thus formed recording layer, a reflection layer made of AlTi with a thickness of 140 nm was formed, whereby an optical recording disk No. 1 of the present invention was fabricated.

PUM

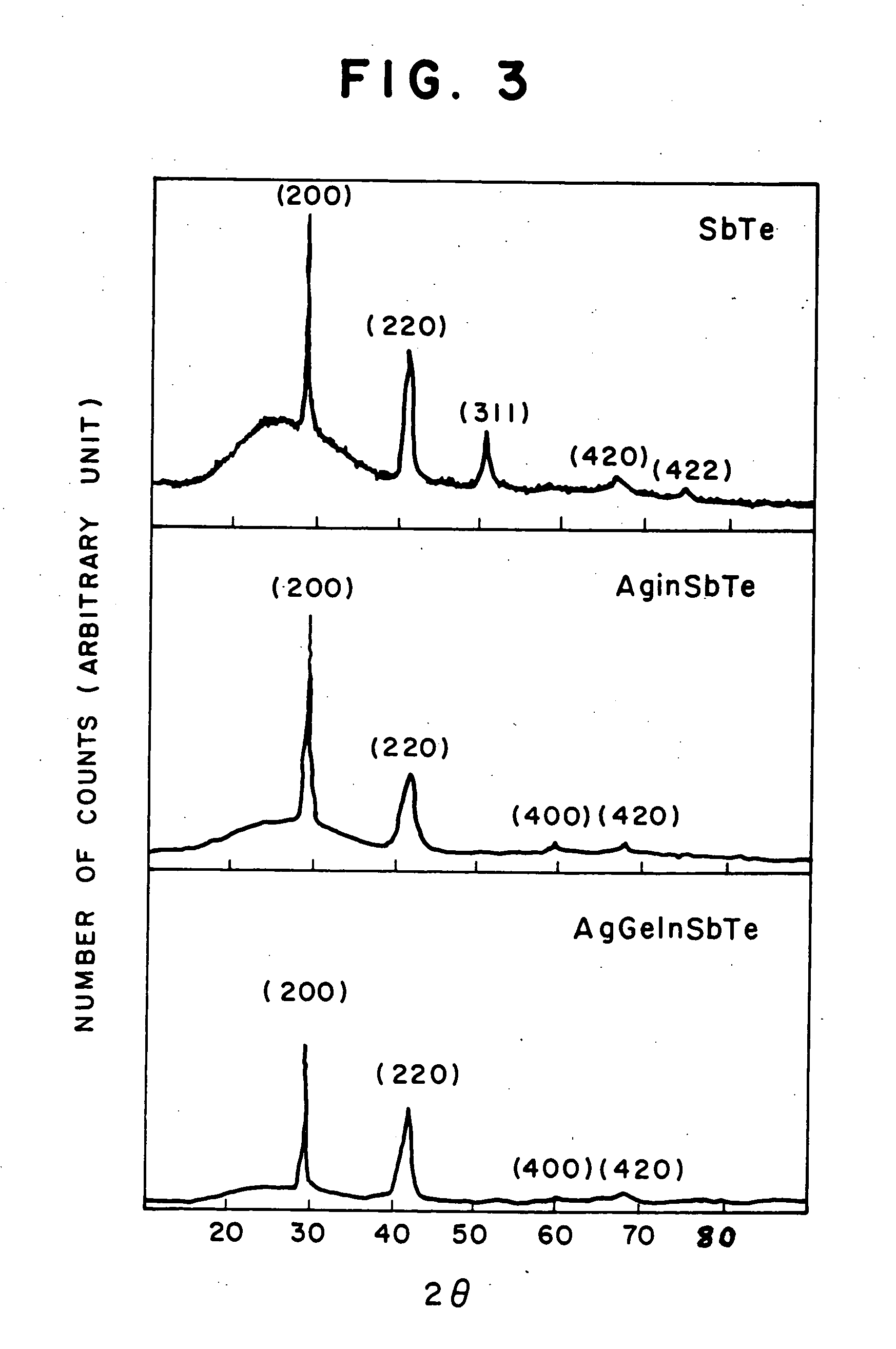

| Property | Measurement | Unit |

|---|---|---|

| Bragg (2θ) angle | aaaaa | aaaaa |

| Bragg (2θ) angle | aaaaa | aaaaa |

| Bragg (2θ) angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com