Template system for locating and cutting wall or ceiling openings

a technology for locating and cutting ceiling openings, applied in the direction of cables, instruments, constructions, etc., can solve the problems of affecting the alignment and attachment of the wall plate covering the outlet, affecting the stability, and being less able to support and secure the gang box, so as to achieve quick and efficient positioning of cutouts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

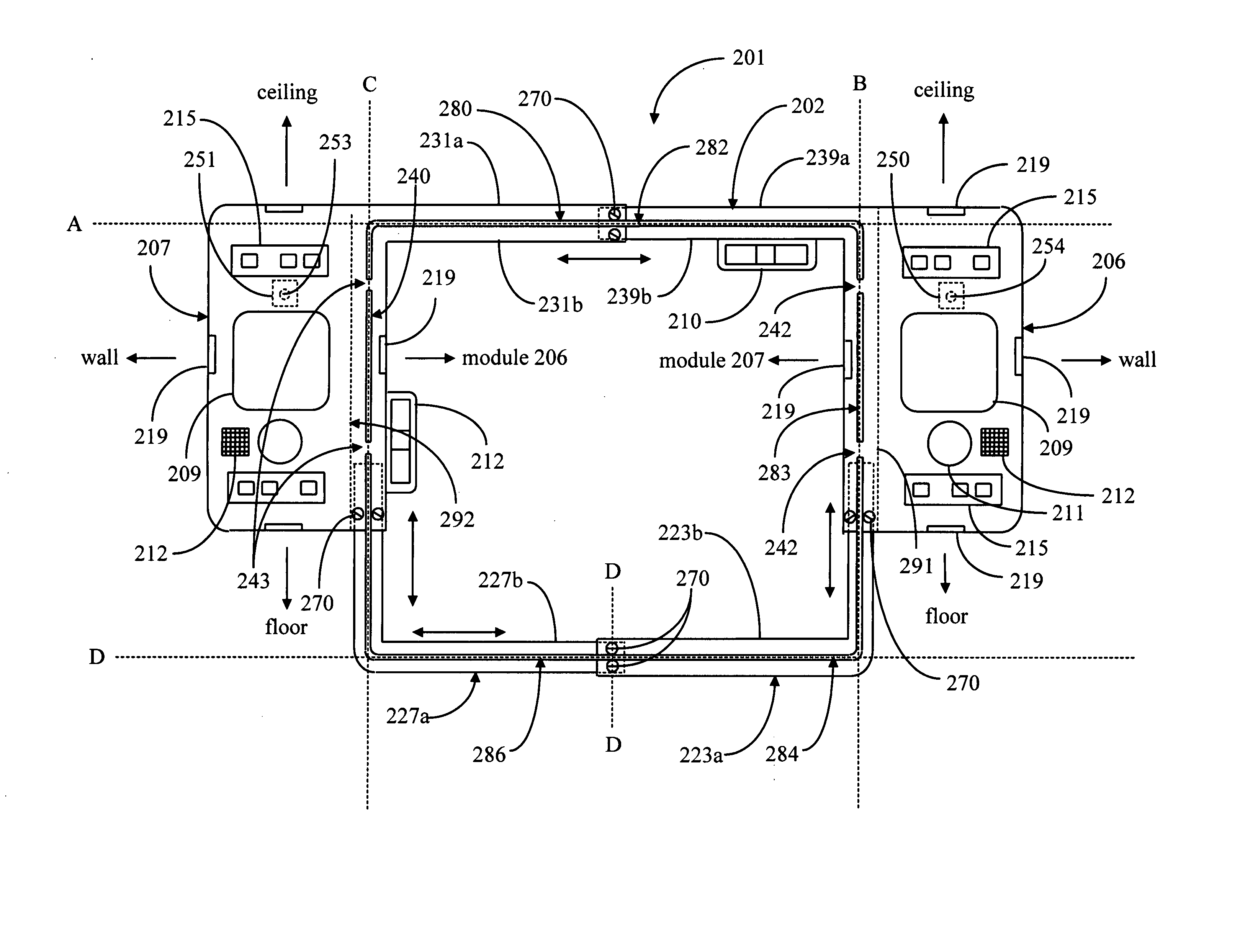

[0036]FIG. 1 illustrates an outline for an opening to be cut into a section of drywall, for both a single and a dual gang box opening, located adjacent to, and aligned with a vertical framing stud within a wall, to which a gang box is to be mounted. Drywall 11 covers stud 13 as is typical in the construction of a wall. Typically the outline of a rectangular cutout for a gang box is marked or scribed upon the outer surface of drywall 11, in a preferred position for installing either a single or dual gang box to stud 13. In order for proper alignment of the newly installed gang box, the left vertical edge of the cutout outline, represented by line 20 in the illustration, is adjacent to, and aligned with the right vertical edge of stud 13, represented as surface 15. In the illustration an outline for the cutout required for a single-gang opening is represented by the rectangular shape formed by line 19 intersected by lines 21 and 22, the rectangular outline having a width of dimension ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com