Height-adjustment mechanism for an armrest

a technology of height adjustment and armrest, which is applied in the direction of chairs, vehicle components, vehicle arrangements, etc., can solve the problems of low quality, design may not appear to be of high quality, and the user may not feel the quality of the armrest adjustment mechanism, and achieve the effect of low cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

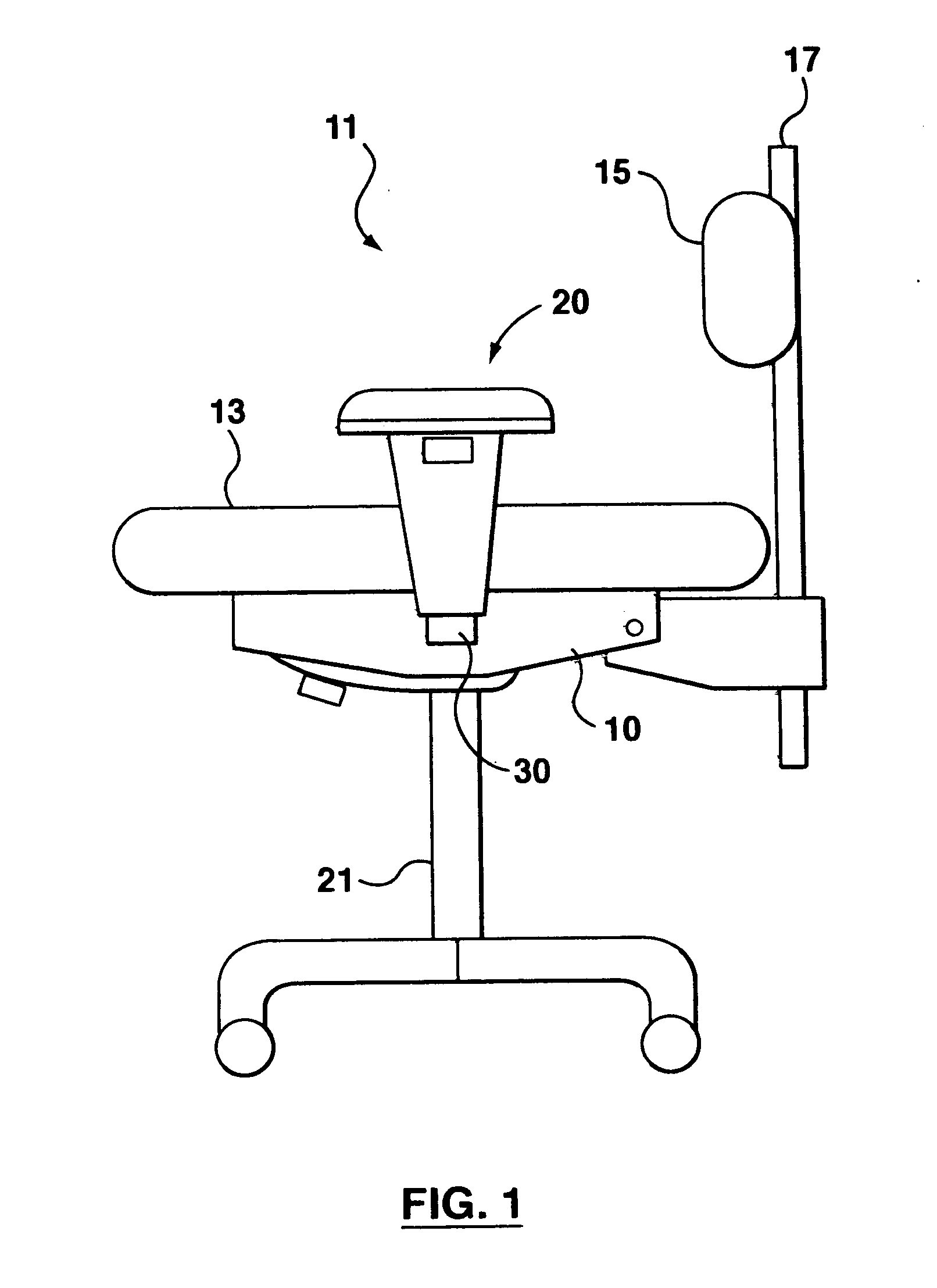

[0026] Referring to FIG. 1, shown is an illustrative chair 11 that may embody the present invention. The chair 11 has a chair seat 13 mounted on a chair seat frame 10 and supported by a chair seat support 21. A backrest 15 is supported on a backrest support 17, and the backrest support 17 is mounted on the chair seat frame 10. The chair 11 may further include a pair of armrests, each armrest including a height-adjustment mechanism 20 supported on an armrest support 30.

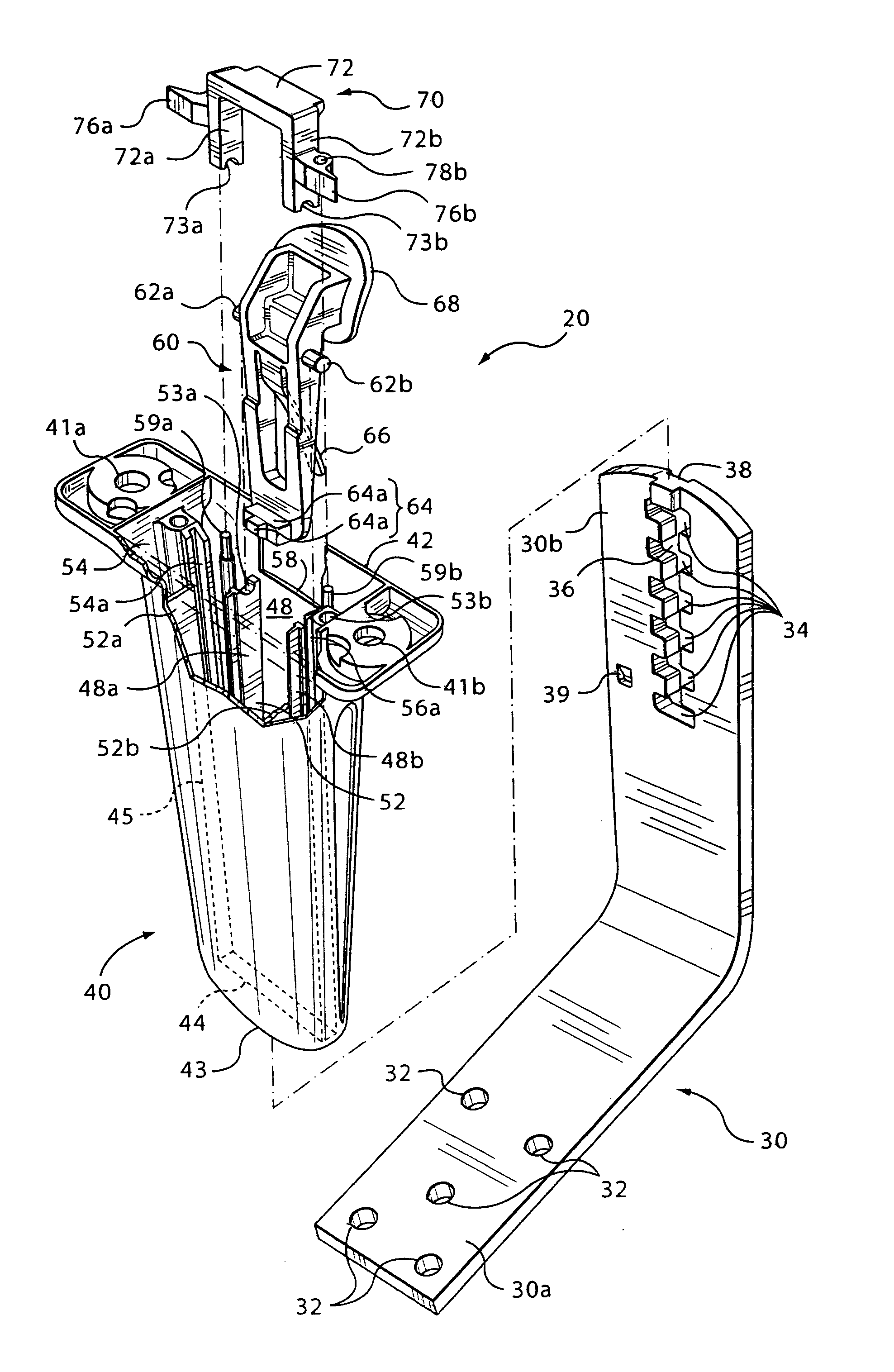

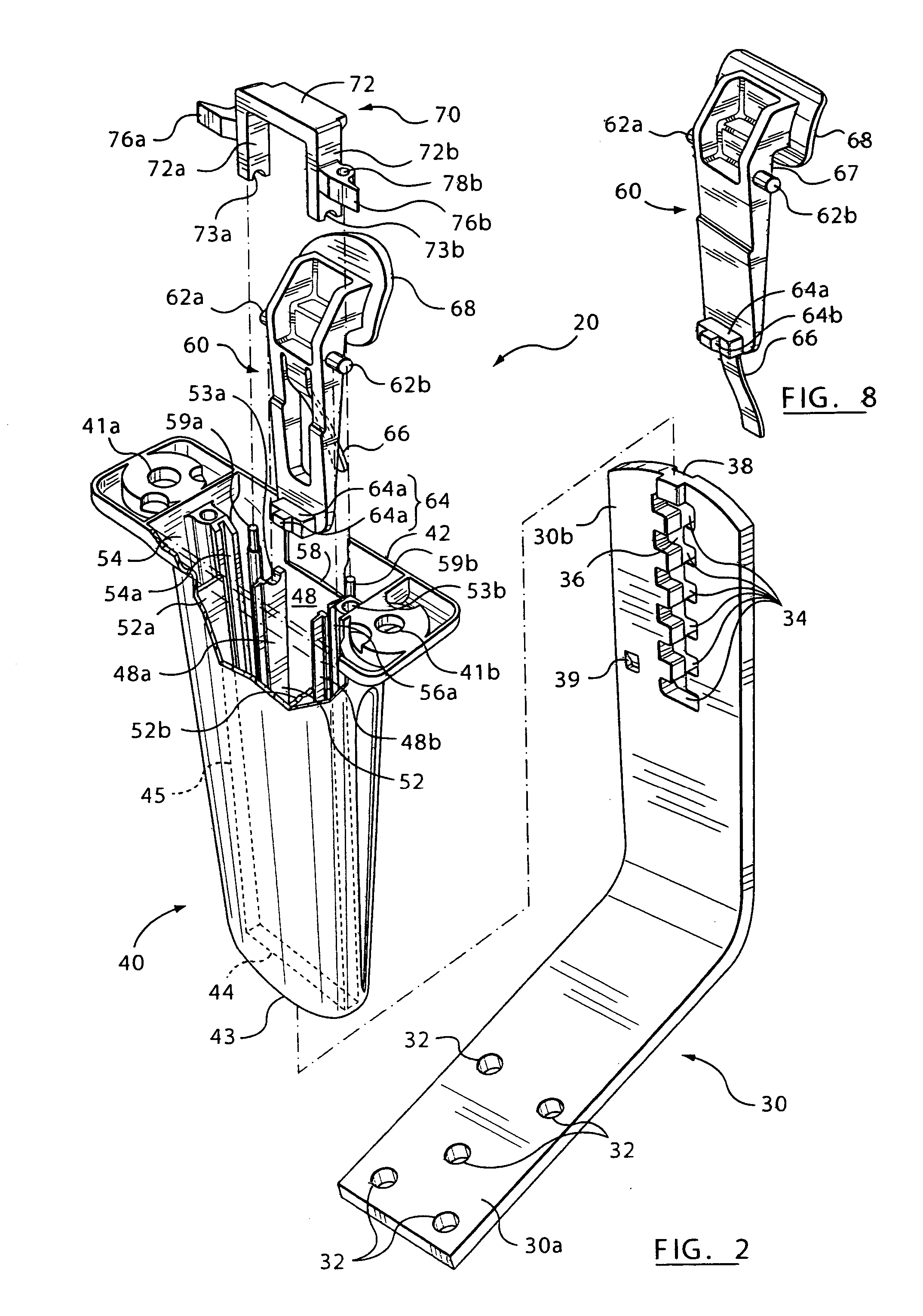

[0027]FIG. 2 shows an exploded perspective view of a height-adjustment mechanism 20 in accordance with an exemplary embodiment of the invention. As shown, the height-adjustment mechanism 20 may include a sleeve 40, a leverage body 60, and a locking member 70. The sleeve 40, with leverage body 60, are adapted to mount to, and engage, the armrest support 30, as explained below.

[0028] In the exemplary embodiment, the support 30 is an L-shaped bar having a first arm 30a and a second arm 30b. In use, the first arm 30a is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com