Shock absorber for a rifle

a shock absorber and rifle technology, applied in the direction of weapons, butts, weapon components, etc., can solve the problems of recoil leaving shoulders sore or bruised, force transfer to be absorbed largely by the user, etc., to prevent the immediate impact force transfer of momentum, reduce the likelihood of injury or bruise, and reduce the impact correspondingly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is a shock absorber for use on a rifle, particularly shotguns and other rifles having a significant recoil kick.

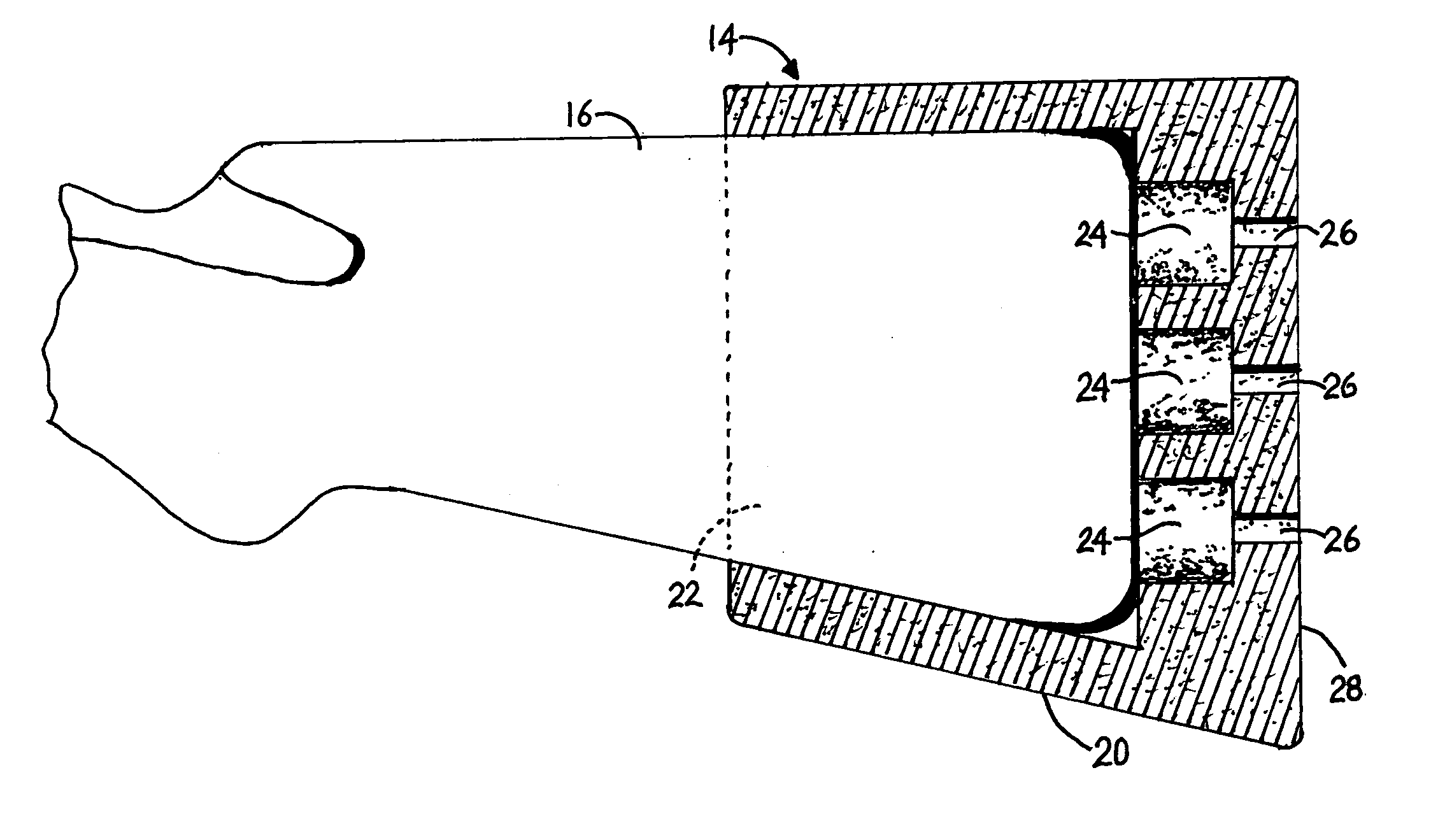

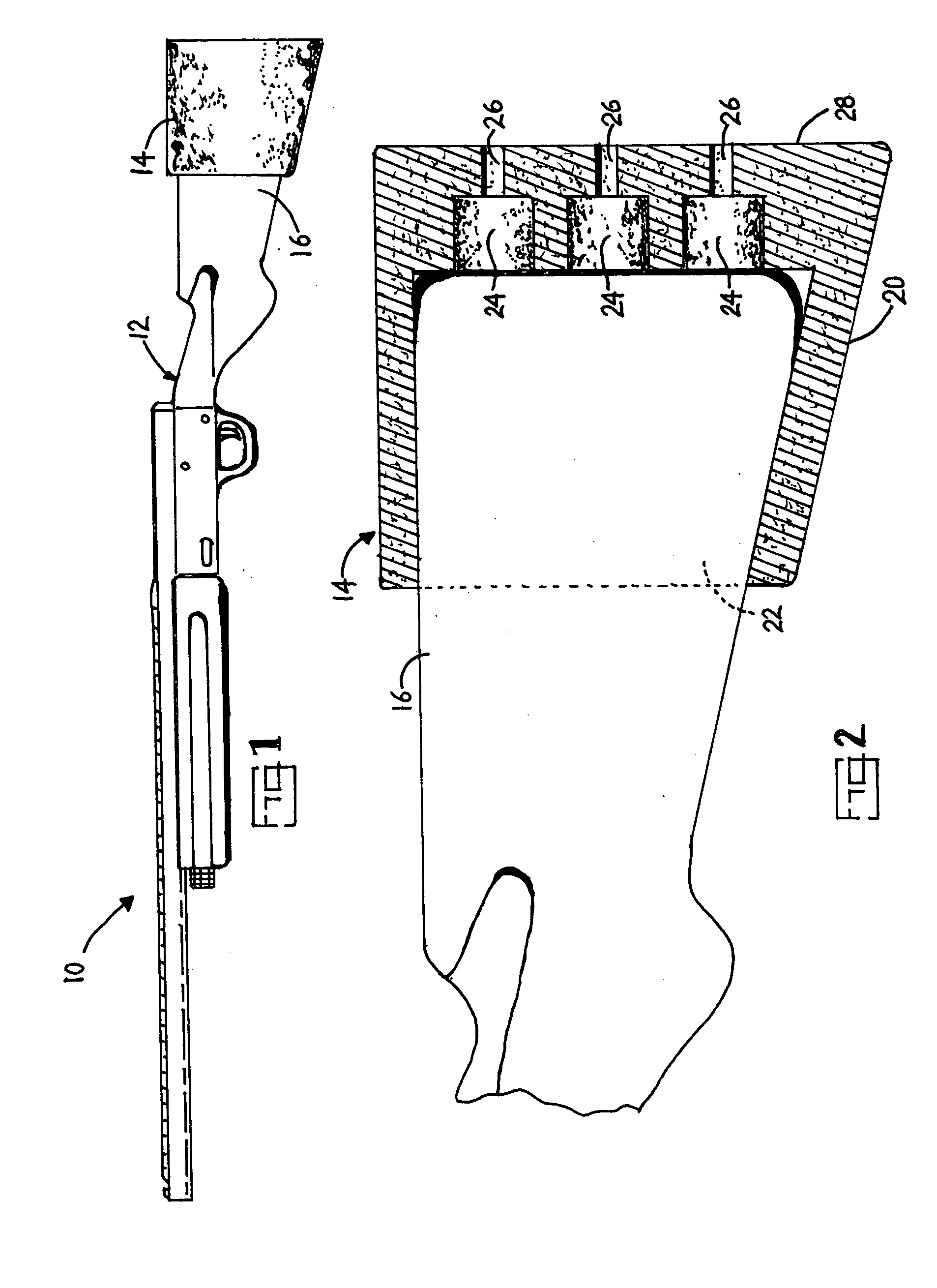

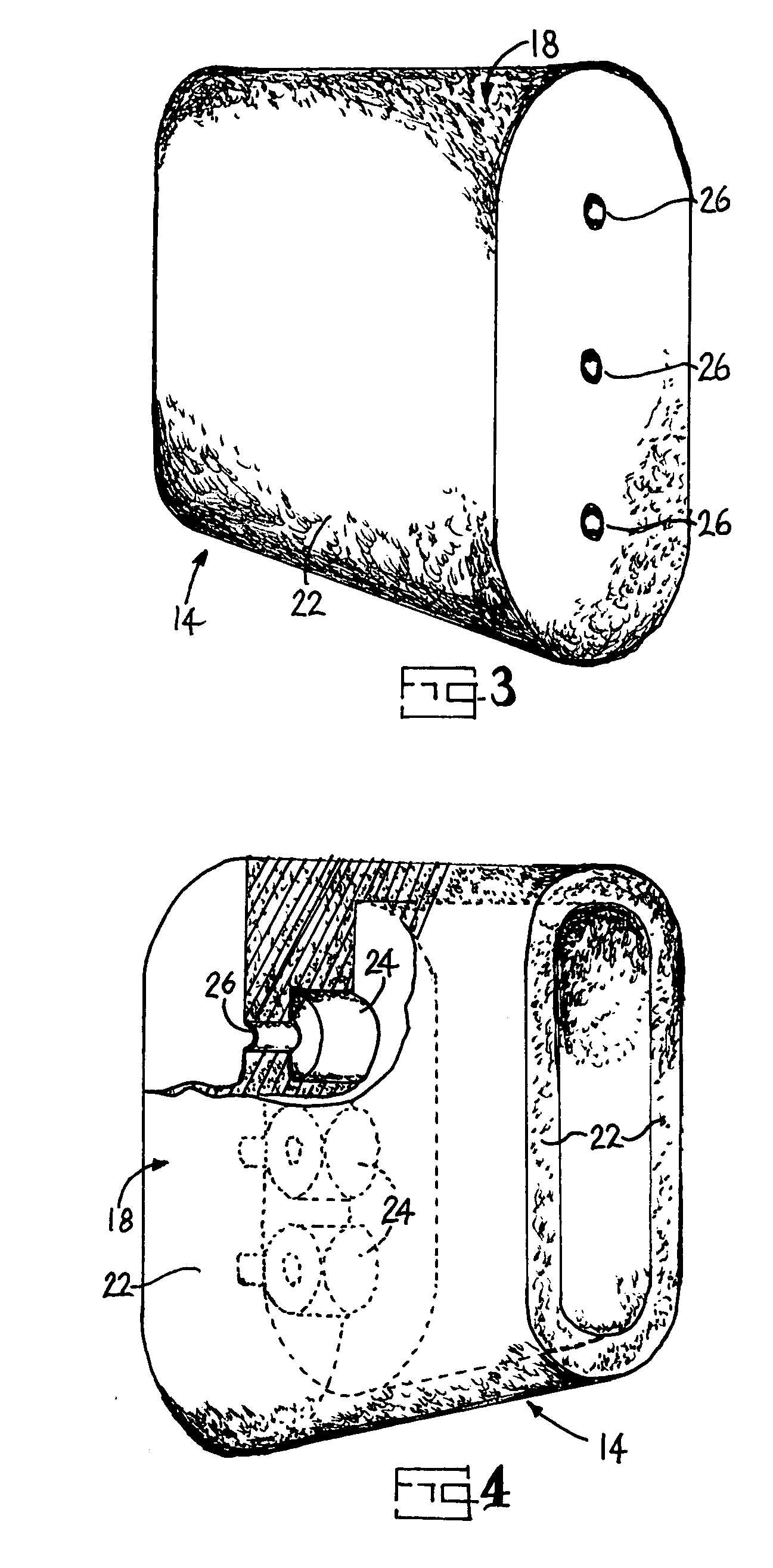

[0019] The shock absorber according to the present invention and as illustrated in the accompanying drawings fits like a sleeve or cup over a portion of the stock of a rifle. The rifle of FIG. 1, generally indicated by the reference number 10 has a stock 12 with a shock absorber 14 carried thereon. Shock absorber 14 thus is positioned, when rifle 10 is held in the standard shoulder-firing position, between stock 12 and the shoulder of the user with the butt 16 of rifle 10 (see FIG. 2) firmly seated in shock absorber 14.

[0020] Shock absorber 14 is made entirely of foam rubber, either synthetic or natural foam rubber, and preferably of neoprene (closed cell flexible) or urethane foam. It may be made in colors such as camouflage colors, hunter orange or in basic black. Because it is resilient, it may be slipped onto and off stock 12 easily just ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com