Gas-operated guns with demountable and interchangeable barrel sections and improved actuation cylinder construction

a technology of actuation cylinder and gas-operated guns, which is applied in the direction of weapons, weapon components, etc., can solve the problems of direct injection of gas into the working mechanism, serious dispersion of the resulting shots, etc., and achieve the effect of less expensive and greater accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

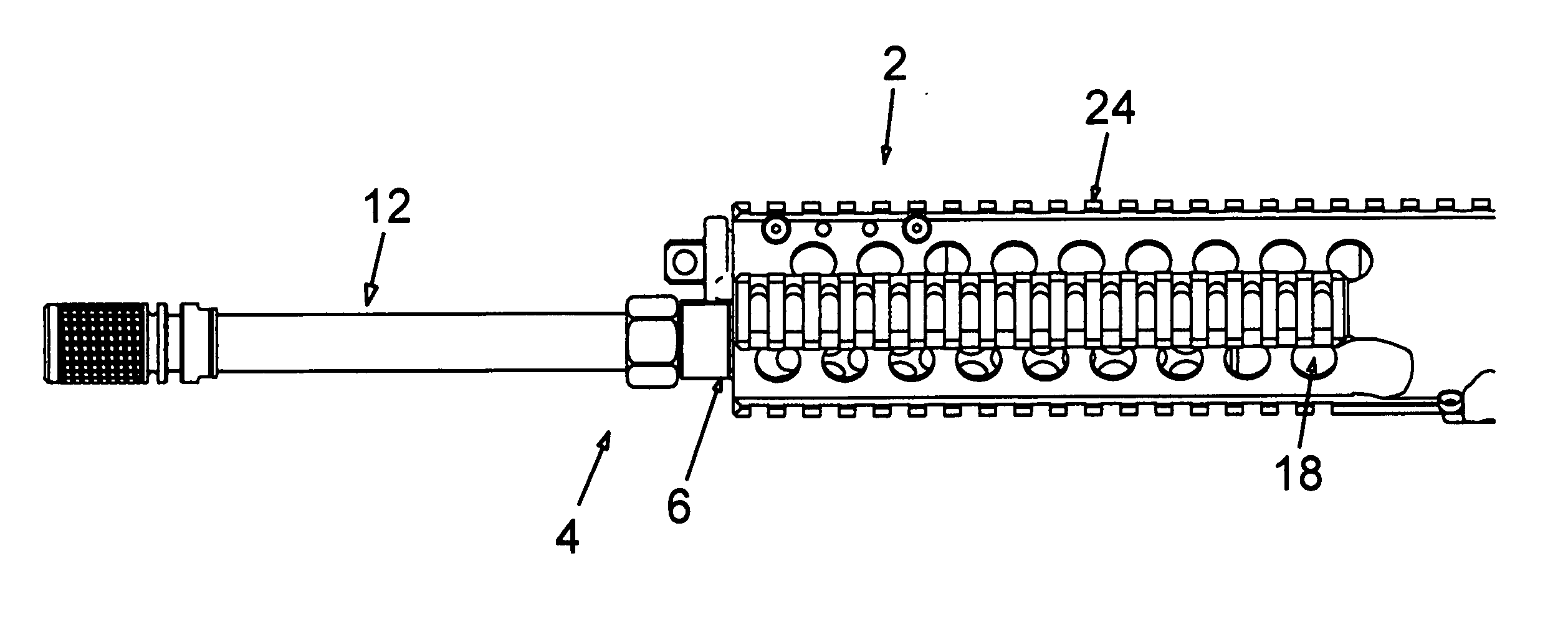

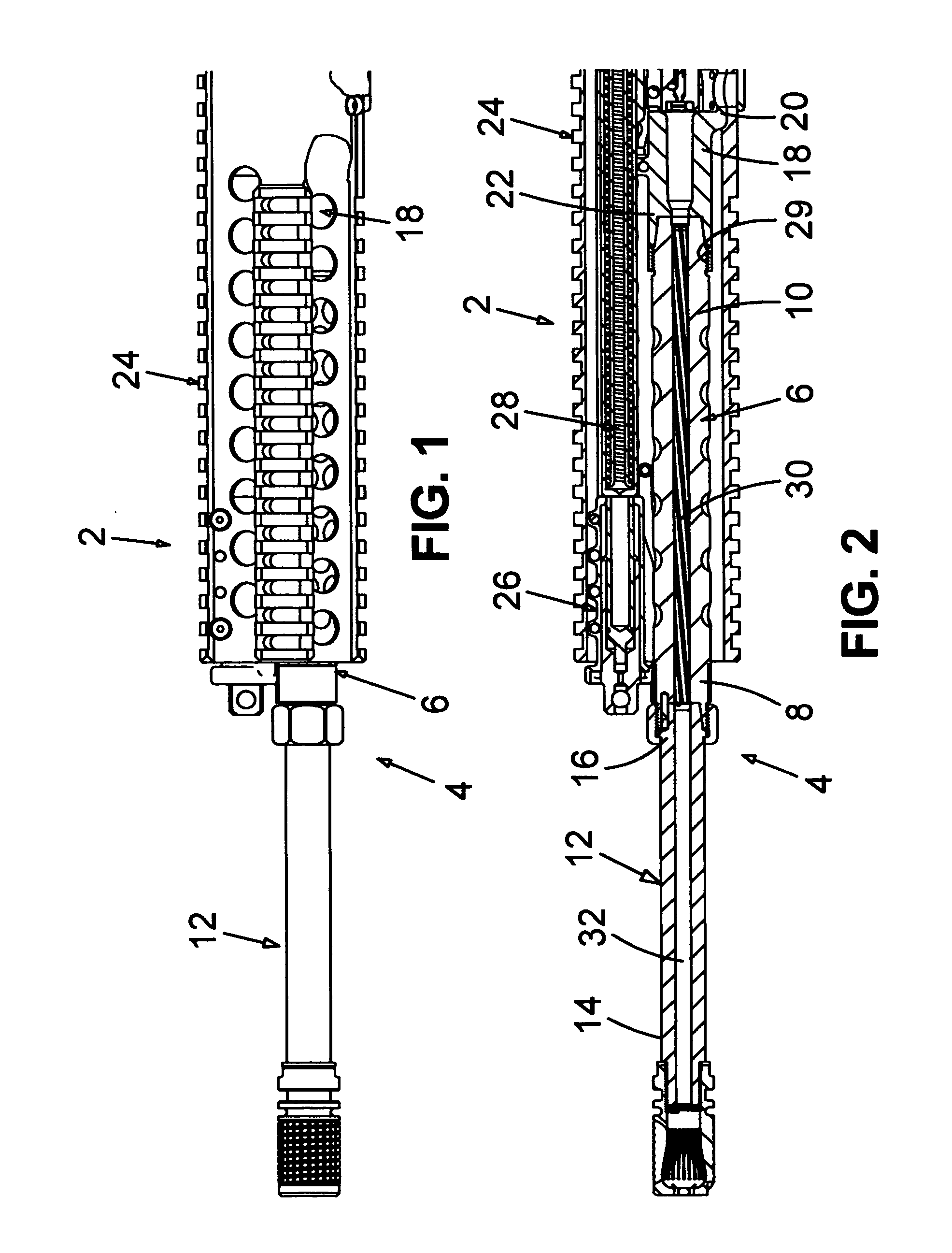

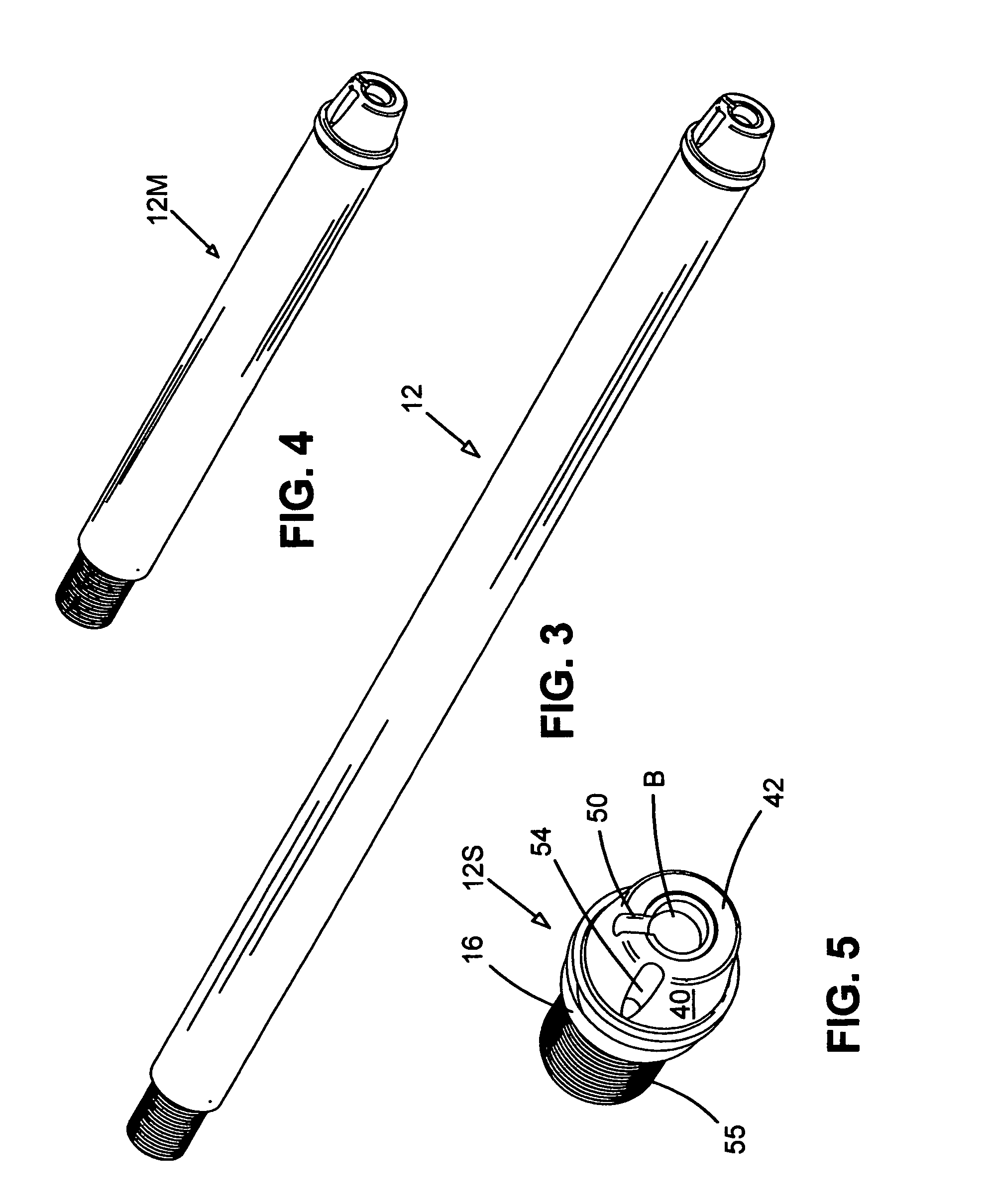

[0050] Referring in detail to the drawings beginning with FIGS. 1 & 2, the improved gun 2 of the invention comprises a bisectional barrel 4 having a breech section 6 defined by a breech front portion 8 and a breech rear portion 10 plus a demountable and interchangeable muzzle section 12 defined by a muzzle front portion 14 and a muzzle rear portion 16.

[0051] The gun 2 includes chamber 18 that is defined by a rear end 20 and front end 22. Chamber 18 is operatively connected by its front end 22 to breech rear portion 10.

[0052] The receiver 24 constitutes a major component of the gun 2. The rear end 20 of chamber 18 is mounted to receiver 24 to accept ammunition therein in known fashion of operation of M16 rifles. Also, an actuation cylinder 26 is mounted to the receiver 24 in manner explained further below.

[0053] Located within the receiver 24 there is a mechanical system 28, operated by the actuation cylinder 26, to perform in known manner the gun functions of unlocking, extractio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com