Device for producing an unvulcanized rubber member for tire manufacturing

a technology of rubber parts and rubber parts, which is applied in the direction of tyre beads, transportation and packaging, and other domestic objects, can solve the problems of deterioration of the external appearance deformation of the surface decrease of the commercial value of the fabricated tire, so as to achieve efficient expulsion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

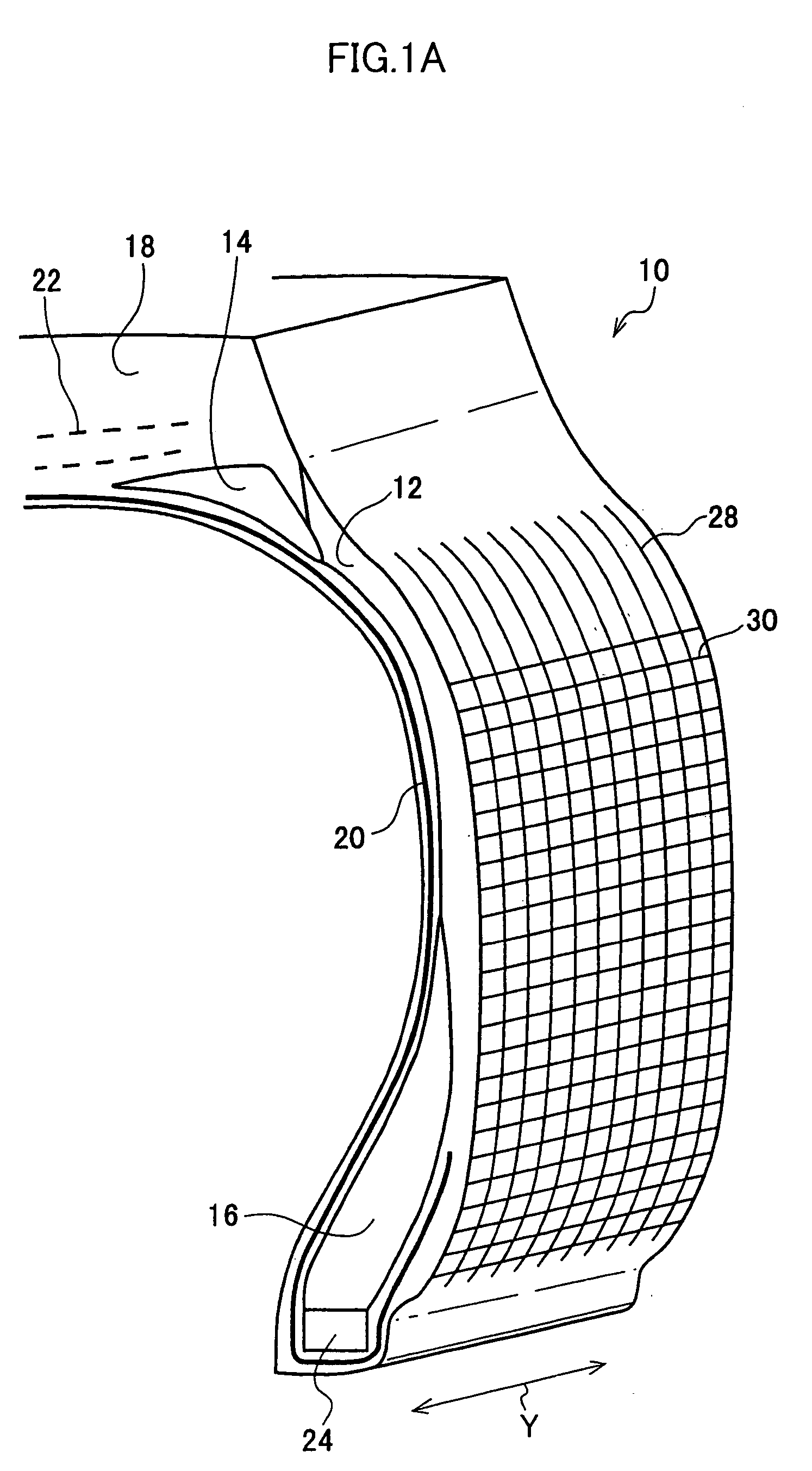

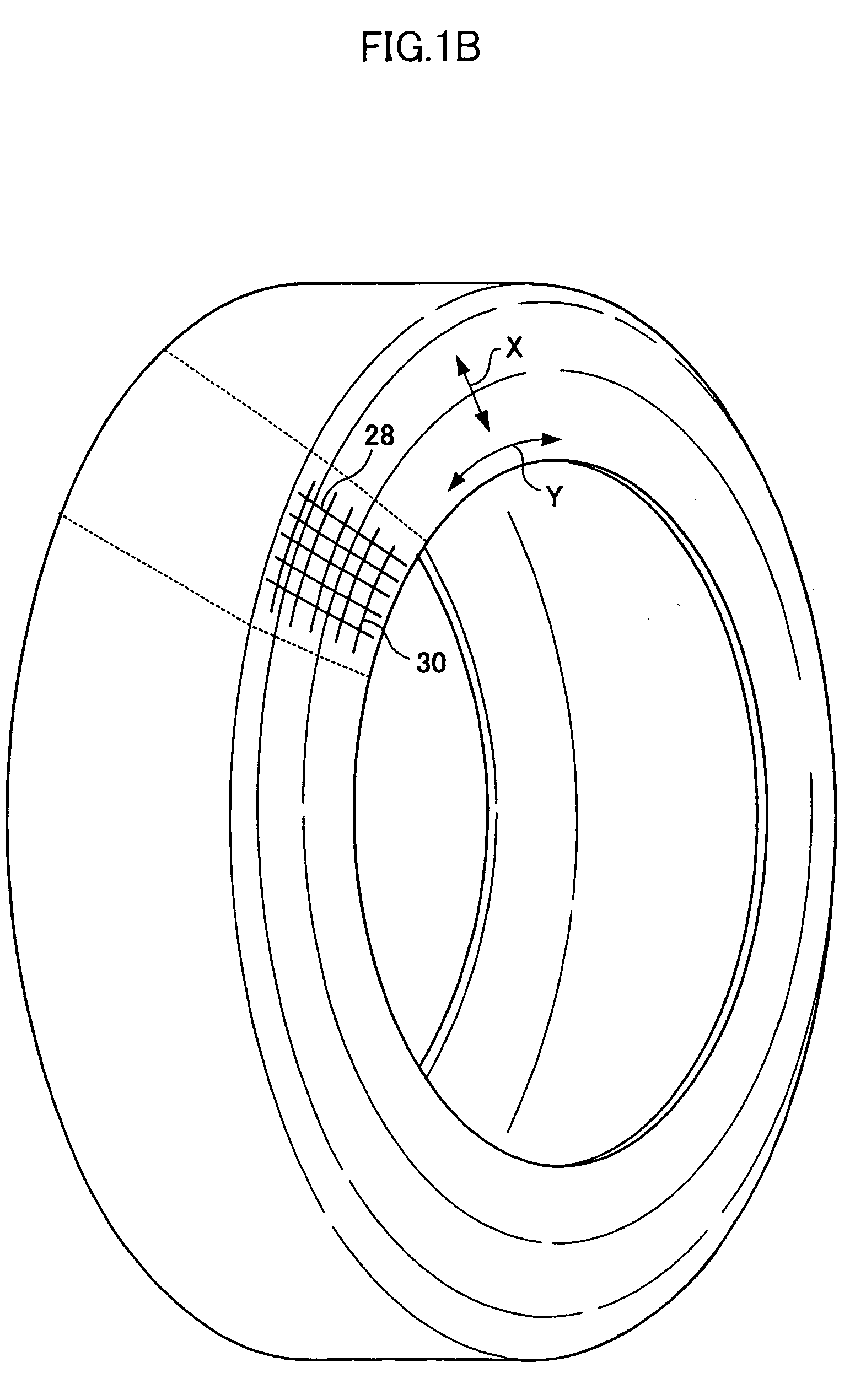

[0045]FIG. 1A shows a cross section of a green tire 10 prior to vulcanization. In FIG. 1A, there are shown a sidewall portion structural member 12, a belt-cushion portion structural member 14, a bead-reinforcement portion structural member (bead filler) 16, a tread portion structural member 18, a carcass 20, a belt 22, and a bead core 24. Further, FIG. 1B is a schematic perspective view of the entire green tire including the portions shown in FIG. 1A (however, only structures necessary to understand FIG. 1A are shown).

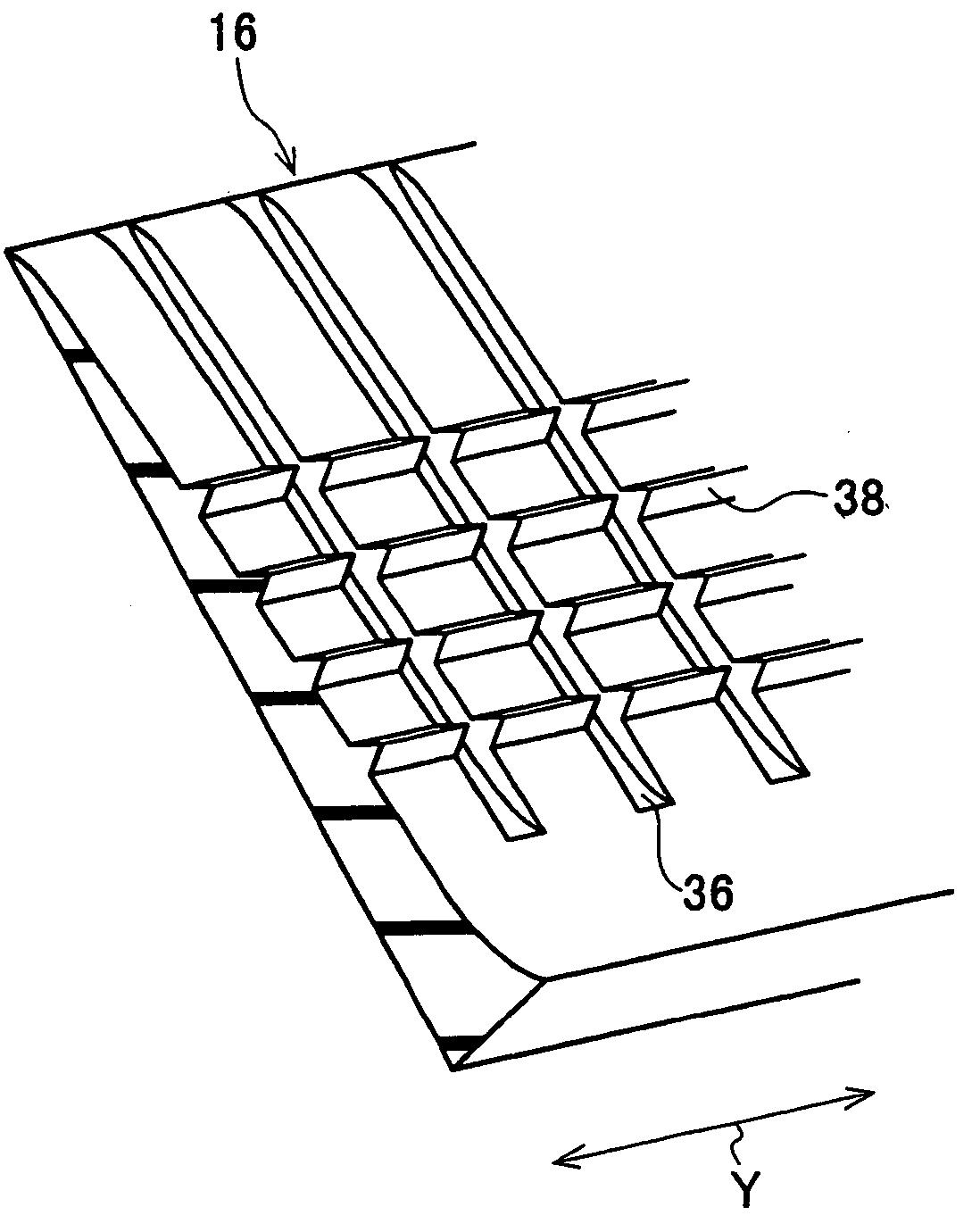

[0046] As shown in FIG. 2, a plurality of grooves 28 which extend along a direction corresponding to a radial direction of a tire (direction of arrow X), and a plurality of rib-protrusions 30 that intersect the grooves 28 and extend in a direction corresponding to a circumferential direction of the tire (direction of arrow Y) are formed on a surface of the sidewall portion structural member 12 formed of unvulcanized rubber (i.e., a surface of the side wall portion str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com