Drive circuit for el display panel

a drive circuit and display panel technology, applied in static indicating devices, instruments, relays, etc., can solve the problems of difficult to implement a large high-resolution display panel of the former type, difficult control methods, relatively expensive,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

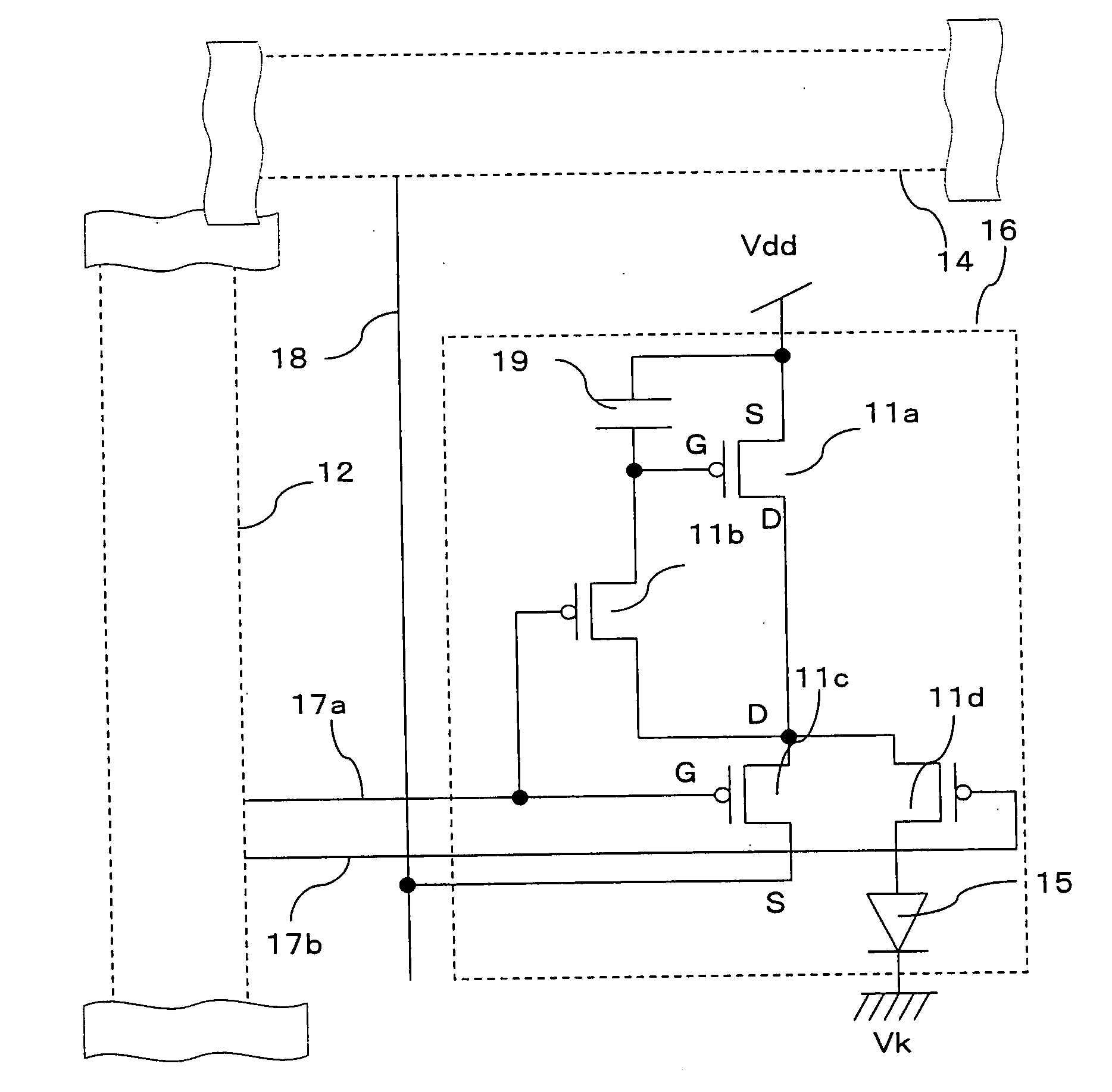

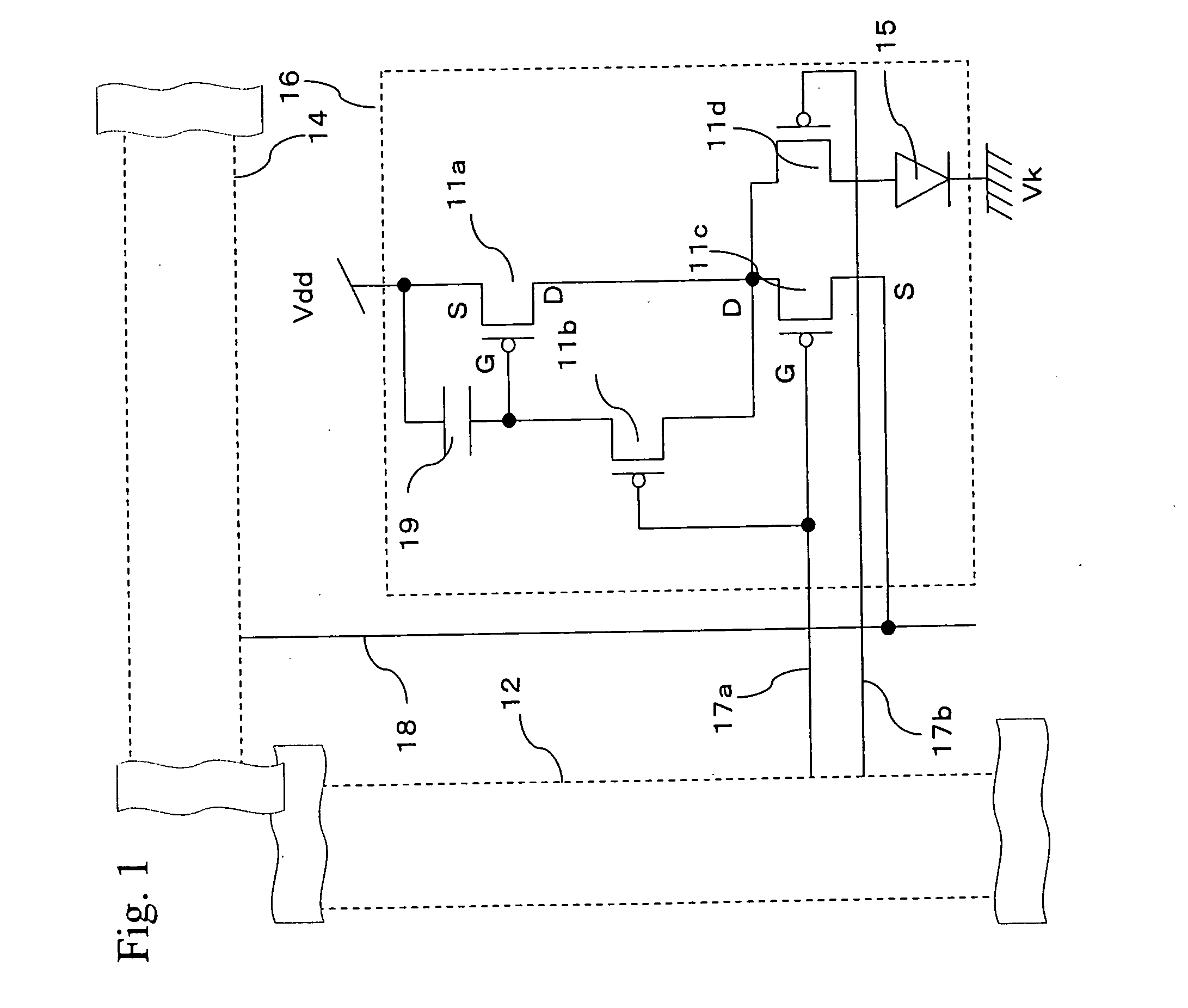

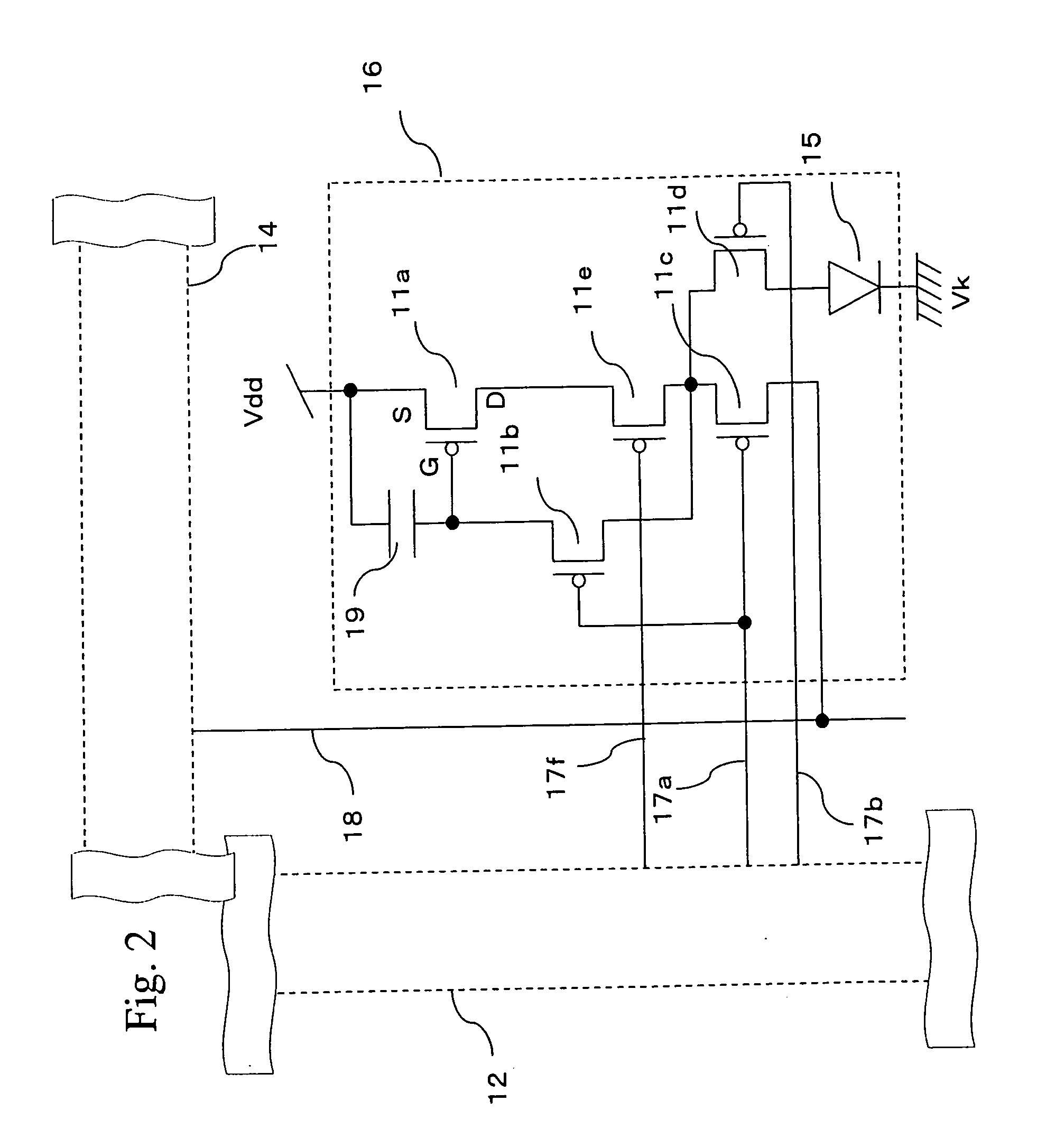

Image

Examples

Embodiment Construction

[0458] Some parts of drawings herein are omitted and / or enlarged / reduced herein for ease of understanding and / or illustration. For example, in a sectional view of a display panel shown in FIG. 11, a thin encapsulation film 111 and the like are shown as being fairly thick. On the other hand, in FIG. 10, a sealing lid 85 is shown as being thin. Some parts are omitted. For example, although the display panel according to the present invention requires a phase film such as a circular polarizing plate to prevent reflection, the phase film is omitted in drawings herein. This also applies to the drawings below. Besides, the same or similar forms, materials, functions, or operations are denoted by the same reference numbers or characters.

[0459] Incidentally, what is described with reference to drawings or the like can be combined with other examples or the like even if not noted specifically. For example, a touch panel or the like can be attached to a display panel in FIG. 8 to provide an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com